4

English

(d)

Where flammable gas may leak, where there is

carbon fiber, or ignitable dust suspension in the

air, or where volatile flammables such as thinner

or gasoline are handled. Operating the unit in such

conditions can cause a fire.

•

Take adequate measures to prevent the outside unit from

being used as a shelter by small animals. Small animals

making contact with electrical parts can cause

malfunctions, smoke, or fire. Instruct the customer to

keep the area around the unit clean.

•

Install the power supply and control wires for the indoor

and outdoor units at least 3.5 feet away from televisions

or radios to prevent image interference or noise.

Depending on the radio waves, a distance of 3.5 feet

may not be sufficient to eliminate the noise.

•

Dismantling the unit, treatment of the refrigerant, oil and

additional parts must be done in accordance with the

relevant local, state, and national regulations.

•

Do not use the following tools that are used with

conventional refrigerants: gauge manifold, charge hose,

gas leak detector, reverse flow check valve, refrigerant

charge base, vacuum gauge, or refrigerant recovery

equipment.

•

If the conventional refrigerant and refrigerator oil are

mixed in R-410A, the refrigerant may deteriorate.

•

This air conditioner or heat pump is an appliance that

should not be accessible to the general public.

•

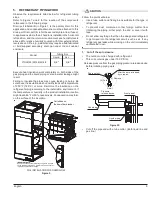

As design pressure is 450 psi, the wall thickness of field-

installed pipes should be selected in accordance with

the relevant local, state, and national regulations.

2.

BEFORE INSTALLATION

•

Entrust installation to the place of purchase or a qualified

serviceman. Improper installation could lead to leaks and, in

worse cases, electric shock or fire.

•

Use of unspecified parts could lead to the unit failing, leaks

and, in worse cases, electric shock or fire.

•

Be sure to read this manual before installing the indoor unit.

•

Be sure to mount an air filter (part to be procured in the field)

in the suction air passage in order to prevent water leaking,

etc.

The accessories needed for installation must be retained in

your custody until the installation work is completed. Do

not discard them.

1.

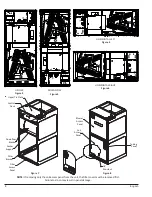

Decide upon a line of transport.

2.

Leave the unit inside its packaging while moving, until

reaching the installation site. Where unpacking is

unavoidable, use a sling of soft material or protective plates

together with a rope when lifting, to avoid damage or

scratches to the unit.

Be sure to check the type of R-410A refrigerant to be used

before installing the unit.

(Using an incorrect refrigerant will prevent normal operation

of the unit.)

For the installation of an outdoor unit, refer to the installation

manual attached to the outdoor unit.

2.1

PRECAUTIONS

•

Be sure to instruct customers how to properly operate the

unit (operating different functions, and adjusting the

temperature) by having them carry out operations themselves

while looking at the operation manual.

•

Do not install in locations where the air contains high levels

of salt such as that near the ocean and where voltage

fluctuates greatly such as that in factories, or in vehicles or

vessels.

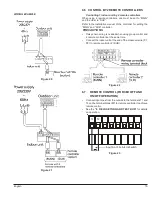

2.2

OPTIONAL ACCESSORIES

This indoor unit requires one of the operation remote controls

listed below.

Wired type

BRC1E73, BRC2A71

Remote Controller

FOR THE FOLLOWING ITEMS, TAKE SPECIAL CARE

DURING CONSTRUCTION AND CHECK AFTER

INSTALLATION IS FINISHED.

ITEMS TO BE CHECKED AFTER COMPLETION OF WORK