19

English

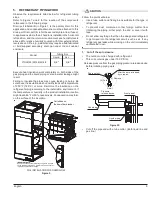

9.5.1

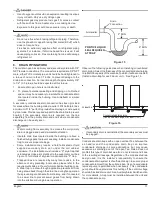

ELECTRIC HEATER ON/OFF

TEMPERATURE SETTING

When an auxiliary heater is installed and controlled by the indoor unit,

the heater ON/OFF temperatures, Ton and Toff, can be selected

individually by switching the 1st code and 2nd code according

to

the

following table.

Heater

2 Stage

nd

Heater

1 Stage

st

Heat Pump

ON

ON

ON

OFF

OFF

OFF

TEMPERATURE

1.8°F

1.8°F

Toff + S*

Ton + S*

SP (Set Point)

*“

S” Value varies automatically based on the room temperature trend

ELECTRIC HEATER & HEAT PUMP OPERATION MODE

Figure 25

ON

OFF

SP (Set Point)

Heater

2

nd

Stage

ON

OFF

1.8

F

1.8

F

Ton + S*

Heater

1

st

Stage

TEMPERATURE

*‘‘S” Value varies automatically based on the room temperature trend

ELECTRIC HEATER OPERATION MODE

Figure 26

Perform on-site setting using the remote controller.

Temperature difference must be 3.6ºF or more between “Ton”

and “Toff” to activate setting(s).

°F (°C)

01*

02

03

04

05

06

Ton

1

-7.2

(-4.0)

-6.3

(-3.5)

-5.4

(-3.0)

-4.5

(-2.5)

-3.6

(-2.0)

-2.7

(-1.5)

Toff

2

-3.6

(-2.0)

-2.7

(-1.5)

-1.8

(-1.0)

-0.9

(-0.5)

0

(0)

0.9

(0.5)

SYMBOL

MODE

NO.

FIRST

CODE

SECONE CODE NO.

11(21)

*Factory Set

9.6

DRY MODE 2.0

14(24)-5-XX

•

Choose dry mode settings as per following table:

XX

01 (*)

02

DRY

mode

Set Point =

Room

Temperature

Set Point

became same

as cooling

mode set point

Mode No. 14(24)

First Code No. 5

Second Code No. XX

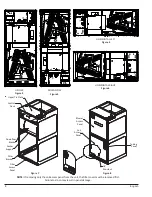

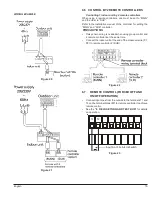

10.

ACCESSORIES

1.

Installation of the humidifier, economizer and air purifier (UV

lamp)

Humidifier, economizer (11.5VA each terminal) and air

purifier (UV lamp) are sold separately. For the method of

installation, refer to the manual provided with each optional

product.

•

If the unit is installed with an electric heater, install the optional

product at a location where it is not exposed directly to the

heat from the electric heater. Direct exposure to heat can

result in an equipment malfunction or fire.

2.

Connect the wires.

•

Run the wires through knockout hole.

•

Connect the wires to the terminal block of the product. Refer

to wiring diagram inside the unit for wire connections.

3.

On-site setting of air purifier/humidifier.

Terminal Name

Input/output signal

CONTROL ON/OFF

Outputs: indoor unit ON

(AC 24V) 11.5VA or less

ECONOMIZER 2

Output: indoor unit cooling

THERMO ON (AC 24V) 11.5VA or less

ECONOMIZER 1

Receives input: Economizer operation ON (Dry

contact)

HUMIDIFIER

Receives input: Humidifier operation ON (Dry

contact)

AIR CLEANER

Receives input: Air purifier operation ON (Dry

contact)