21

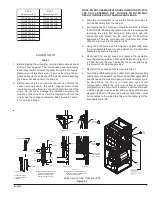

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

NOTES:

1. PLACE RED WIRES ON 208 V TERMINAL OF 2-TRANSFORMER

(TR1/TR2) FOR 208 VAC OPERATION.

2. MANUFACTURER'S SPECIFIED REPLACEMENT PARTS MUST BE

USED WHEN SERVICING.

3. IF ANY OF THE ORIGINAL WIRES AS SUPPLIED WITH THIS UNIT

MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING

MATERIAL HAVING A TEMPERATURE RATING OF AT LEAST 105°C.

USE COPPER CONDUCTORS ONLY.

4. UNIT MUST BE PERMANENTLY GROUNDED AND CONFIRM TO

N.E.C AND LOCAL CODES.

5. DISCARD CONNECTOR PL1 WHEN INSTALLING OPTIONAL HEAT

KIT.

6. REMOVE SHORT RED CIRCUITING WIRE AND PUT AUX ALARM

SWITCH WHEN INSTALLING AUX ALARM SWITCH.

7. USE N.E.C CLASS 2 WIRE.

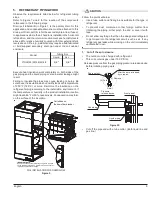

INTEGRATED CONTROL:

POWER/HEATER KIT/

DISCONNECT SWITCH

CONNECTOR

PL1, PL2

COMPONENT CODES:

F1U, F2U

TR1, TR2

TRANSFORMER

FUSE LINK

COLOR CODES:

BL - BLUE

RD - RED

YL - YELLOW

OR - ORANGE

BL - BLACK

GY - GREY

BR - BROWN

GR - GREEN

WH - WHITE

PU - PURPLE

LOW VOLTAGE

LOW VOLTAGE FIELD

HIGH VOLTAGE

HIGH VOLTAGE FIELD

JUNCTION

TERMINAL

PLUG CONNECTION

EQUIPMENT GND

FIELD GROUND

0140A00500-A

X1A

X3A

X38A

BS1

X12A

X13A

HAP

X8A

THERMISTOR

(HEAT EXCHANGER 1, 2)

MPU

MULTI

TENANT

(OPTION)

EEV COIL

M

K1R

K3R

TB6

TB8

K2R

HEATER KIT

OUTPUT

LEARN

PS

TB5

TB4

(ACC-OUT)

3

6

5

9

8

7

10

11

12

RD

BK

RD

BR

BL

BL

RD

FLASH

WRITER

OR

GY

RD

YL

BK

PU

YL

HEATER KIT

BK

GR

GROUND LUG

CONNECTION DISABLED

INSTALLING AUX ALARM (ALARM)

24VAC

COM

COM

208

VAC

230

VAC

208

VAC

230

VAC

TR1

(SEE NOTE 1)

TR2

(SEE NOTE 1)

H2P

(COM STAT)

H3P (RX DATA)

X33A

PCB

(OPTION)

REMOTE SENSOR

(OPTION)

X4A

X35A

X23A

CAPACITY SETTING

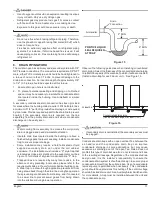

X1M

T1

P2

P1

T2

F2

1

2

R

C

ECONOMIZER (OPTION)

HUMIDIFIER (OPTION)

AIR CLEANER (OPTION)

EXTERNAL CONTACT (OPTION)

OUTPUT FOR

CONTROL ON/OFF

(OPTION)

OUTPUT FOR

ECONOMIZER 2

(OPTION)

X7A

FAN

1

ECM MOTOR

BK

RD

PL1

PL2

9

3

2

6

5

4

7

8

1

BK

RD

DISCONNECT SWITCH WIRING

PL1

PL2

9

7

8

4

5

6

3

2

1

PL3

PL4

TRANSFORMER

CONNECTOR

PL3, PL4

RELAY IN

(ACC-IN)

BK

RD

GY BL

X5A

TB1

TH1

TB2

TR1

TB10

TB3

TH2

TR2

TB7

COM

F1U

F2U

SEE NOTE 7

TB5

TB4

~ ~

WH

BR

BL

GR

RD

BK

BK

RD

RD

208/230

VAC

~ ~

TRANSMISSION WIRING

REMOTE CONTROLLER WIRING

(SEE NOTE 4)

(SEE NOTE 5)

TO

24VAC

BK

2

4

WH

(SEE NOTE 6)

WIRING ADAPTER

INDOOR UNIT PCB

RD

F1

MOTOR

X2M

RELAY OUT

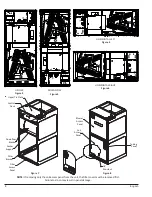

12. Wiring Diagram