Installation manual

5

R REMQ10~16P8 + REMHQ12P8Y1B

VRVIII System air conditioner

4PW48463-1A

6.

R

EFRIGERANT

PIPING

6.1.

Installation tools

Make sure to use installation tools (gauge manifold charge hose,

etc.) that are exclusively used for R410A installations to withstand the

pressure and to prevent foreign materials (e.g. mineral oils such as

SUNISO and moisture) from mixing into the system.

(The screw specifications differ for R410A and R407C.)

Use a 2-stage vacuum pump with a non-return valve which can

evacuate to –100.7 kPa (5 Torr, –755 mm Hg).

6.2.

Selection of piping material

1.

Foreign materials inside pipes (including oils for fabrication)

must be 30 mg/10 m or less.

2.

Use the following material specification for refrigerant piping:

■

Size: determine the proper size referring to chapter

"6.6. Example of connection" on page 9

.

■

Construction material: phosphoric acid deoxidized seamless

copper for refrigerant.

■

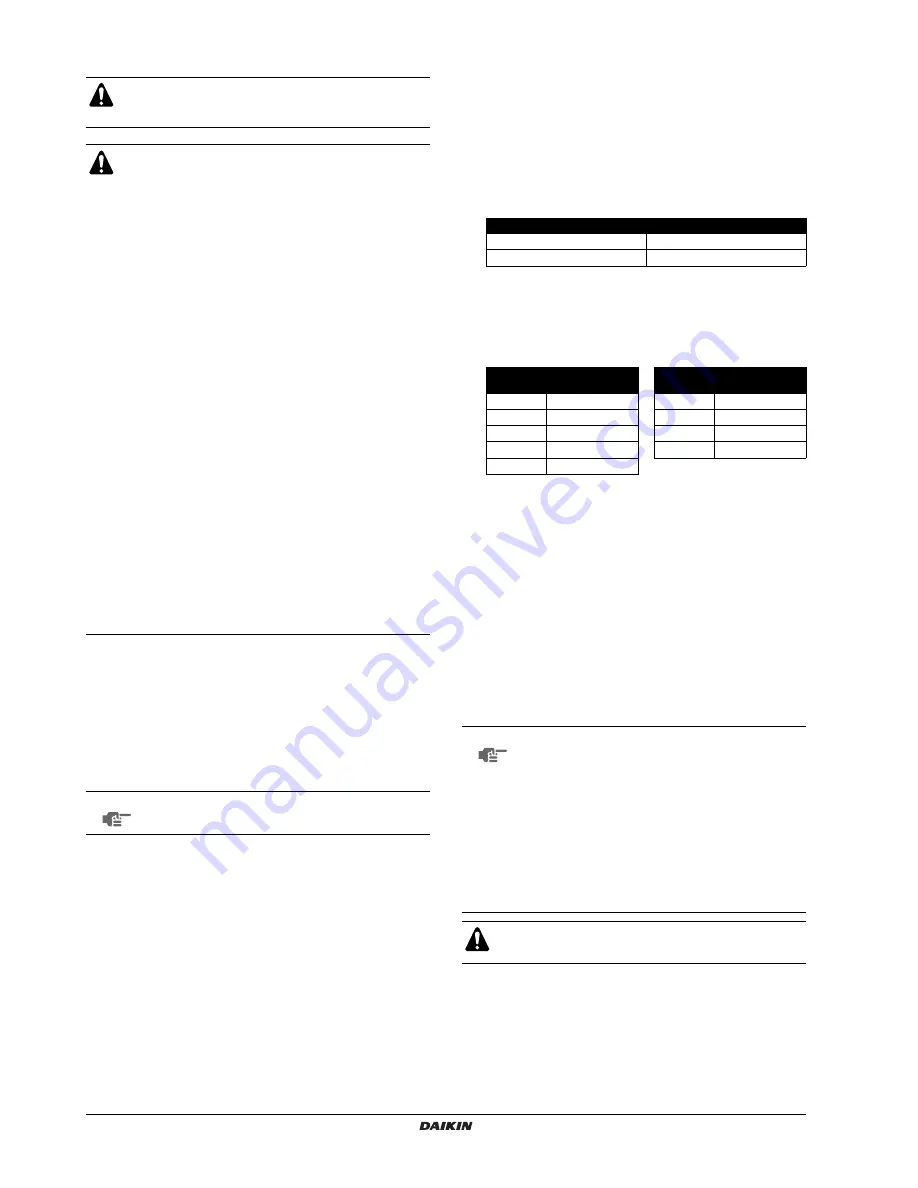

Temper grade: use piping with temper grade in function of the

pipe diameter as listed in the table below.

■

The pipe thickness of the refrigerant piping should comply

with relevant local and national regulations. The minimal pipe

thickness for R410A piping must be in accordance with the

table below.

3.

Make sure to use the particular branches of piping that have

been selected referring to chapter

"6.6. Example of connection"

on page 9

.

4.

In case the required pipe sizes (inch sizes) are not available, it is

also allowed to use other diameters (mm sizes), taken the

following into account:

■

select the pipe size nearest to the required size.

■

use the suitable adapters for the change-over from inch to

mm pipes (field supply).

6.3.

Pipe connection

Be sure to perform a nitrogen blow when brazing and to read the

paragraph

"Caution to be taken when brazing refrigerant piping" on

page 5

first.

Do not insert fingers, rods or other objects into the air

inlet or outlet. When the fan is rotating at high speed, it

will cause injury.

Use R410A to add refrigerant.

All field piping must be installed by a licensed refrigeration

technician and must comply with relevant local and

national regulations.

Caution to be taken when brazing refrigerant piping

Do not use flux when brazing copper-to-copper refrigerant

piping. (Particularly for the HFC refrigerant piping)

Therefore, use the phosphor copper brazing filler metal

(BCuP) which does not require flux.

Flux has extremely harmful influence on refrigerant piping

systems. For instance, if the chlorine based flux is used, it

will cause pipe corrosion or, in particular, if the flux

contains fluorine, it will damage the refrigerant oil.

Be sure to perform a nitrogen blow when brazing. Brazing

without releasing nitrogen into the piping will create large

quantities of oxidized film on the inside of the pipes,

adversely affecting valves and compressors in the

refrigerating system and preventing normal operation.

After completing the installation work, check that the

refrigerant gas does not leak.

Do not open stop valves until all field wiring is according to

the specifications (refer to

"8. Field wiring" on page 12

),

the checking of the unit has been completed and all

installation conditions are fulfilled (refer to

"10. Checking of

unit and installation conditions" on page 17

).

Toxic gas may be produced if the refrigerant gas leaks into

the room and comes in contact with a source of fire.

Ventilate the area immediately in the event of a leak.

In the event of a leak, do not touch the leaked refrigerant

directly. Frostbite may be caused.

NOTE

Make sure the pump oil does not flow oppositely into

the system while the pump is not working.

Pipe Ø

Temper grade of piping material

≤

15.9

O

≥

19.1

1/2H

O = Annealed

1/2H = Half hard

Pipe Ø

Minimal thickness

t (mm)

Pipe Ø

Minimal thickness

t (mm)

6.4

0.80

22.2

0.80

9.5

0.80

28.6

0.99

12.7

0.80

34.9

1.21

15.9

0.99

41.3

1.43

19.1

0.80

NOTE

The pressure regulator for the nitrogen released when

doing the brazing should be set to 0.02 MPa or less.

(See figure 10)

Do not use anti-oxidants when brazing the pipe joints.

Residue can clog pipes and break equipment.

1

Refrigerant piping

2

Location to be brazed

3

Nitrogen

4

Taping

5

Manual valve

6

Regulator

7

Nitrogen

Summary of Contents for REMQ8P9Y1B

Page 36: ...4PW48463 1A Copyright Daikin...