6 Configuration

Installation and operation manual

14

EWAQ016~ EWYQ016~064CAW

Packaged air-cooled water chiller

4P489435-1B – 2017.10

To continue the configuration of the system, it is required to give

some input to the PCB of the unit. This chapter will describe how

manual input is possible by operating the pushbuttons/DIP switches

on the PCB and reading the feedback from the LEDs.

INFORMATION

If you get confused in the middle of the process, push BS1.

Then it returns to setting mode 1 (H1P is off).

6.2.2

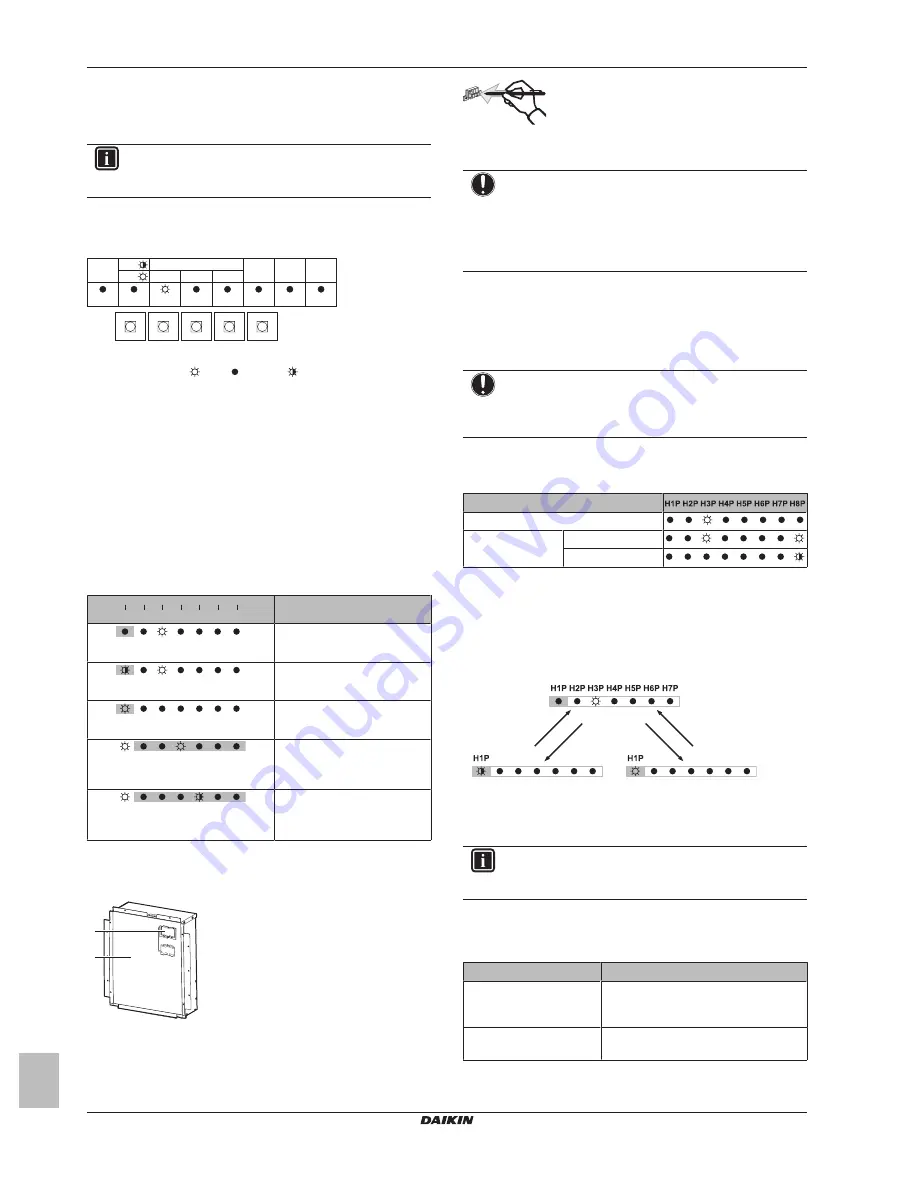

Field setting components

The components to make field settings are as follows:

BS2

SET

BS1

MODE

BS3

RETURN

BS4

TEST

BS5

RESET

H7P

MODE

TEST:

L.N.O.P. DEMAND

C/H SELECT

HWL:

IND MASTER SLAVE

MULTI

H1P

H2P

H3P

H4P

H5P

H6P

H8P

BS1~BS5

Pushbuttons

H1P~H8P

LEDs

ON (

) OFF ( ) Flashing (

)

Pushbuttons

Use the pushbuttons to make the field settings.

BS1

MODE: For changing the set mode

BS2

SET: For field setting

BS3

RETURN: For field setting

BS4

Not used

BS5

Not used

LEDs

The LEDs give feedback about the field settings, which are defined

as [Mode-Setting]=Value.

H1P

Shows the mode

H2P~H7P

Shows the settings and values, represented in binary code

H8P

NOT used for field settings, but used during initialisation

Example:

H1P H2P H3P H4P H5P H6P H7P

-

+

+

+

+

+

[

H1P

32 16

8

4

2

1]

Description

(H1P OFF)

Default situation

(H1P flashing)

Mode 1

(H1P ON)

Mode 2

+

+

+

+

+

0

0

8

0

0

0

(H2P~H7P = binary 8)

Setting 8

(in mode 2)

+

+

+

+

+

0

0

0

4

0

0

(H2P~H7P = binary 4)

Value 4

(in mode 2)

6.2.3

To access the field setting components

Remove the inspection cover to carry out field settings.

b

a

Operate the switches and pushbuttons with an insulated stick (such

as a closed ball-point pen) to avoid touching of live parts.

Make sure to re-attach the inspection cover into the electrical

component box cover after the job is finished.

NOTICE

Make sure that all outside panels, except for the service

cover on the electrical component box, are closed while

working.

Close the lid of the electrical component box firmly before

turning on the power.

6.2.4

To access mode 1 or 2

After the units are turned ON, the display goes to its default

situation. From there, you can access mode 1 and mode 2.

Initialisation: default situation

NOTICE

Be sure to turn on the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

Turn on the power supply of the outdoor unit, and turn on the

external operation switch. After initialisation, the display indication

state will be as below (default situation when shipped from factory).

Single unit

Multi-unit

Left unit (master)

Right unit (slave)

If the default situation is not displayed after 10~12 minutes, check

the malfunction code. Solve the malfunction code accordingly.

The HAP LED flashes to indicate normal microcomputer operation.

Switching between modes

Use BS1 to switch between the default situation, mode 1 and

mode 2.

BS1 [5 s]

BS1

BS1

BS1

a

c

b

a

Default situation (H1P OFF)

b

Mode 1 (H1P flashing)

c

Mode 2 (H1P ON)

BS1

Press BS1.

BS1 [5 s]

Press BS1 for at least 5 s.

INFORMATION

If you get confused in the middle of the process, press BS1

to return to the default situation.

6.2.5

To use mode 1

Mode 1 is used to monitor the status of the unit.

What

How

Accessing monitoring

mode 1

Once mode 1 is selected (push BS1

one time), you can select the wanted

setting. It is done by pushing BS2.

To quit and return to the

initial status

Press BS1.

Summary of Contents for EWAQ016CAW

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ...4P489435 1B 2017 10 Copyright 2017 Daikin 4P489435 1 B 00000004...