D - KIMAC00512-09EN - 20/40

Relief Valves

As a safety precaution and to meet code requirements, each chiller is equipped with pressure relief valves

located on the coil condenser, evaporator, heat recovery condenser (if supplied) and liquid receiver for the

purpose of relieving excessive refrigerant pressure (caused by equipment malfunctioning, fire etc.) to the

atmosphere.

Oil Heater

The oil separator is equipped with an immersion electric heater that is installed in a tube that can be

removed without disturbing the oil or opening the refrigerant circuit.

Evaporator water flow and pressure drop

Balance the chilled water flow through the evaporator. The flow rates must fall between the minimum and

maximum values. Flow rates below the minimum values shown will result in laminar flow that will reduce efficiency,

cause erratic operation of the electronic expansion valve and could cause low temperature cut-out. On the other

hand flow rates exceeding the maximum values shown can cause erosion , vibration and may cause the break on

the evaporator water connections and tubes. Measure the chilled water pressure drop through the evaporator at

field installed pressure taps. It is important not to include valve or strainer pressure drop in these readings.

Variable chilled water flow through the evaporator while the compressors are operating is not recommended. Set

points are based upon a constant flow and variable temperature.

Heat Recovery Condenser water flow and pressure drop

Heat recovery condensers are supplied without the headers connection on both water side, entering and

leaving. These Headers must be provided by the installer locally , including the wells pockets for

microprocessor control sensors.

Balance the hot water flow through the heat recovery condenser. The flow rates must fall between the minimum

and maximum values. Flow rates below the minimum values shown will result in laminar flow that will reduce

efficiency, cause erratic operation of the unit and could cause high pressure cut-out. On the other hand flow rates

exceeding the maximum values shown can cause erosion on the condenser water connections and tubes.

Measure the hot water pressure drop through the condenser at field installed pressure taps. It is important not to

include header, valve or strainer pressure drop in these readings. Variable hot water flow through the condenser

while the compressors are operating is not recommended. Set points are based upon a constant flow and variable

temperature.

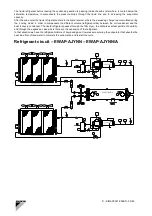

Leaving Connections

Entering Connections

Installer must provide the Headers

between the heat recovery

condenser to have only one supply

water connection and one return

water connection

Summary of Contents for EWAP 800-C18AJYNN

Page 1: ...D KIMAC00512 09EN 1 40 ...