36

Gas

Rate

Range

Nominal

High Stage 3.2 to 3.8" w.c. 3.5" w.c.

Low Stage 1.6 to 2.2" w.c. 1.9" w.c.

Manifold Gas Pressure

Natural Gas

WARNING

HIGH VOLTAGE

Disconnect ALL electrical power and shut off

gas supply before servicing or installing this

unit. Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

WARNING

HIGH VOLTAGE

Disconnect ALL electrical power and shut off gas supply

before servicing or installing.

Gas

Rate

Range

Nominal

High Stage 9.7 to 10.3" w.c. 10.0" w.c.

Low Stage 5.7 to 6.3" w.c. 6.0" w.c.

Propane Gas

Manifold Gas Pressure

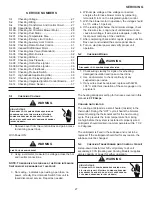

S-308A Checking Hot Surface Ignitor

120V Silicon Nitride Igniter - Daikin Brand model furnaces

use a 120V silicon nitride igniter for ignition. The normal

operating temperature is approximately 2156°F - 2678°F.

At room temperature the igniter ohm reading should be

from 37-68 ohms.

1. Place unit in heating cycle, measure current draw of

ignitor during preheat cycle.

The steady state current at 120V is 0.37 to 0.68

amps.

2. After checking and/or replacing of hot surface ignitor,

reinstall burner compartment door and verify proper

unit operation.

S-309 Checking For Flashback

Flashback will also cause burning in the burner venturi, but

is caused by the burning speed being greater than the gas-

air flow velocity coming from a burner port.

Flashback may occur at the moment of ignition, after a

burner heats up or when the burner turns off. The latter is

known as extinction pop.

Since the end results of flashback and delayed ignition

can be the same (burning in the burner venturi) a definite

attempt should be made to determine which has occurred.

If flashback should occur, check for the following:

1. Improper gas pressure - adjust to proper pressure

(See S-307

CHECKING GAS PRESSURE

).

2. Check burner for proper alignment and/or replace

burner.

3. Improper orifice size - check orifice for obstruction.

S-310 Checking Pressure Switch

The pressure control is a safety device to prevent the

combustion cycle from occurring with inadequate venting

caused by a restricted or blocked vent pipe. In addition

to the inducer pressure switch, S model furnaces have

a “front cover pressure switch” wired in series with the

gas valve. This pressure switch keeps the gas valve

from opening in the event of condensate backing up in

the secondary heat exchanger. This could occur from

improperly connected drains or a plugged drain tube.

WARNING

HIGH VOLTAGE

Disconnect ALL power before servicing or in

-

stalling this unit. Multiple power sources may

be present. Failure to do so may cause proper

-

ty damage, personal injury or death.

1. Remove burner compartment door to gain access to

pressure switch(es).

2. Remove wires from the pressure switch(es) electrical

terminals.

3. Remove the pressure control hose from the control

and interconnect with an inclined manometer as

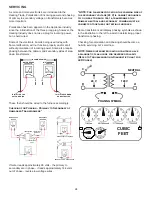

shown in the following figures.

4. With an ohm meter connected across the pressure

switch terminals; with the inducer running the switch

should close and the ohm meter should show a

complete circuit across the pressure switch. If the

switch is not closed, compare the negative pressure

to the closing point specified for the particular switch.

Either the switch is defective or the inducer / venting

system is inadequate.

S-311 High Altitude Application (USA)

A high altitude kit is required for installations above

7,000 ft. Refer to the accessory matrix in this manual to

determine the proper natural gas and LP gas high altitude

kit for your furnace.

S-312 Checking For Delayed Ignition

Delayed ignition is a delay in lighting a combustible mixture

of gas and air which has accumulated in the combustion

chamber.

Furnace design makes this extremely unlikely unless safety

controls have been by-passed or tampered with. Never

bypass or alter furnace controls.

If delayed ignition should occur, the following should be

checked:

SERVICING