25

SERVICING

1/4

cu/ft

1/2

cu/ft

1

cu/ft

2

cu/ft

5

cu/ft

10

90

180

360

720

1800

11

82

164

327

655

1636

12

75

150

300

600

1500

13

69

138

277

555

1385

14

64

129

257

514

1286

15

60

120

240

480

1200

16

56

113

225

450

1125

17

53

106

212

424

1059

18

50

100

200

400

1000

19

47

95

189

379

947

20

45

90

180

360

900

21

43

86

171

343

857

22

41

82

164

327

818

23

39

78

157

313

783

24

37

75

150

300

750

25

36

72

144

288

720

26

34

69

138

277

692

27

33

67

133

265

667

28

32

64

129

257

643

29

31

62

124

248

621

30

30

60

120

240

600

31

--

--

116

232

581

32

28

56

113

225

563

33

--

--

109

218

545

34

26

53

106

212

529

35

--

--

103

206

514

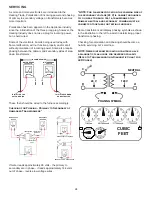

Size of Test Dial

GAS RATE -- CUBIC FEET PER HOUR

Seconds for

One

Revolution

1/4

cu/ft

1/2

cu/ft

1

cu/ft

2

cu/ft

5

cu/ft

36

25

50

100

200

500

37

--

--

97

195

486

38

23

47

95

189

474

39

--

--

92

185

462

40

22

45

90

180

450

41

--

--

--

176

439

42

21

43

86

172

429

43

--

--

--

167

419

44

--

41

82

164

409

45

20

40

80

160

400

46

--

--

78

157

391

47

19

38

76

153

383

48

--

--

75

150

375

49

--

--

--

147

367

50

18

36

72

144

360

51

--

--

--

141

355

52

--

--

69

138

346

53

17

34

--

136

340

54

--

--

67

133

333

55

--

--

--

131

327

56

16

32

64

129

321

57

--

--

--

126

316

58

--

31

62

124

310

59

--

--

--

122

305

60

15

30

60

120

300

GAS RATE -- CUBIC FEET PER HOUR

Seconds for

One

Revolution

Size of Test Dial

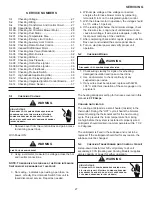

Combustion Quality

Combustion quality can be affected by several factors.

Major factors are venting and draining.

Venting

The venting system should be planned and installed with

the following in mind:

•

Should not be longer than necessary

•

Use 45° elbows rather than 90° elbows when possible

•

Must not sag or otherwise trap condensate

•

Use longest radius fittings possible

•

If using 3" venting, make the transition from 2" to 3" as

close as practically possible

•

Make sure there is no flue gas recirculation into the

combustion air pipe

Condensate Drainage

Furnace combustion can be affected if a furnace is holding

condensate. Check for proper connections of drain

hoses; make sure furnace condensate trap is clean. Make

sure furnace is not improperly sloped. Make sure air

conditioning coil drain is not interfering with furnace drain.

Other Causes

1. Manifold Gas Pressure must be set, the gas being

used, Natural or L.P., high and low firing rates. If

converted to L.P. gas, check size of all orifices.

2. Remove Draft Inducer, Check the integrity of the

gasket between the inducer and the collector box

cover, any air leak here will have a negative effect

on combustion. Check the orifice hole in the collector

box, it must be free or burrs on both sides.

3. Make sure burners are clean, not out of position and

line up correctly with heat exchanger tubes, including

the heat exchanger orifice plate - this is the plate

which mounts to the front panel of the heat exchanger

between the burners and the heat exchanger tubes,

make sure it is not loose, missing a screw or hanging

down between the burners and heat exchanger

causing flame impingement.

4. Make sure the field installed gas line is not binding

and causing distortion of burner assembly.

5. If the furnace is installed as a one pipe system; make

sure the surrounding area and structure are adequate

to provide combustion air.

6. Make sure there are no cabinet air leakes allowing

supply air to affect combustion.

7. If heat exchanger integrity is uncertain, follow

procedures in Service Bulletin SF-041.