20

A

LTERNATE

C

OMBUSTION

A

IR

P

ROVISION

(Upflow / Horizontal models only)

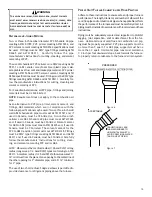

When using the alternate venting location, either in a

horizontal left side down installation or a vertical instal-

lation using down – venting, an alternate combustion air

opening can used. A locating dimple is located on the

right side of the furnace cabinet. The locating dimple is 1

7/8" measured from the front edge of the cabinet in line

with the knock out. To use the alternate combustion air

location:

1. Remove screws and combustion air flange from

cabinet.

2. Insert cabinet plug in unused combustion air hole.

3. Drill a pilot hole at the cabinet dimple (size dictated

by knockout tool used).

4. Use a knockout tool to create a 3" diameter hole

5. Install combustion air flange and secure with screws

removed in step one.

V

ENT

/F

LUE

P

IPE

L

ENGTHS

AND

D

IAMETERS

For installations at or above 7,000 feet altitude, use 3” vent-

ing. Refer to the following table for applicable length, elbows,

and pipe diameter for construction of the vent/flue pipe system.

The tee used in the vent/flue termination must be counted as

an elbow when determining the number of elbows in the piping

system.

1

2

3

4

5

6

7

8

2 or 2 1/2

115

110

105

100

95

90

85

80

3

137

130

123

116

109

102

95

88

2 or 2 1/2

115

110

105

100

95

90

85

80

3

147

140

133

126

119

112

105

98

2 or 2 1/2

60

55

50

45

40

35

30

25

3

120

113

106

99

92

85

78

71

2 or 2 1/2

40

35

30

25

20

15

10

5

3

144

137

130

123

116

109

102

95

2 or 2 1/2

40

35

30

25

20

15

10

5

3

144

137

130

123

116

109

102

95

2 or 2 1/2

95

90

85

80

75

70

65

60

3

144

137

130

123

116

109

102

95

2 or 2 1/2

95

90

85

80

75

70

65

60

3

144

137

130

123

116

109

102

95

2 or 2 1/2

60

55

50

45

40

35

30

25

3

120

113

106

99

92

85

78

71

2 or 2 1/2

40

35

30

25

20

15

10

5

3

103

96

89

82

75

68

61

54

DC97MC1005CNA*

DM97MC0804CNA*

DM97MC1005CNA*

DM97MC1205DNA*

DC97MC0603BNA*

DC97MC0803BNA*

DC97MC0804CNA*

DM97MC0803BNA*

Direct Vent (2 - Pipe) and Non-Direct Vent (1- Pipe)

(6)

Model

Pipe Size

Number of Elbows

DM97MC0603BNA*

1) Maximum allowable limits listed on individual lengths for inlet and flue

and NOT a combination.

2) Minimum requirement for each vent pipe is five (5) feet in length

and one elbow/tee.

3) Tee used in the vent/flue termination must be included when deter-

mining the number of elbows in the piping system.

4) 2 1/2” or 3” diameter pipe can be used in place of 2” diameter pipe.

5) Increased Clearance Configurations using (2) 45 deg. elbows should be

considered equivalent to one 90 deg. elbow.

6) One 90° elbow should be secured to the combustion air intake connec-

tion.

7) For installations at or above 7,000 feet altitude, use 3” venting.

V

ENT

/F

LUE

P

IPE

T

ERMINATIONS

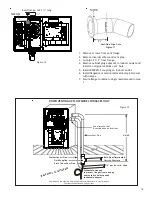

NOTE: If either a 90 degree or 45 degree elbow is used for

termination, it must be pointed downward.

The vent/flue pipe may terminate vertically, as through a

roof, or horizontally, as through an outside wall.

Vertical vent/flue pipe terminations should be as shown in

the following figure. Refer to

Vent/Flue Pipe and Combustion

Air Pipe - Termination Locations

for details concerning loca-

tion restrictions. The penetration of the vent through the

roof must be sealed tight with proper flashing such as is used

with a plastic plumbing vent.

Horizontal vent/flue pipe terminations should be as shown in the

following figure. Refer to

Vent/Flue Pipe and Combustion Air

Pipe - Termination Locations

for details concerning location re-

strictions. The wall penetration should be sealed with sili-

cone caulking material.

NOTE: Terminate both pipes in

the same pressure zone

(same side of roof, no major obstacles between pipes,

etc.).

COMBUSTION AIR INTAKE

(OPTIONAL)

*Not requ ired for

singl e pipe installation

TEE (OPTIONAL)

96

” M

AX

. -

3”

MI

N.

RO

OF

LIN

E

12” MIN

HEIGHT DIFFERENCE

BETWEEN

INTAKE AND VENT

12” MIN TO ROOF OR HIGHEST

ANTICIPATED SNOW LEVEL

Figure 13

STRAIGHT

ELBOWS

Figure 14