IM 1040 • VAV ACTUATOR

6

www.DaikinApplied.com

s

TarT

-u

p

p

roCedures

Enabling autozero module

CAUTION

If an Autozero Module is used, do not enable MTR3 (valve 2).

NOTICE

For a controller without an Autozero Module, the damper

is commanded closed to get a zero airflow reading during

calibration. For a controller with an Autozero Module, the

damper is closed only for the first calibration after controller

initialization or power up.

If an Autozero Module is used, enable it by setting CAL

MODULE to Y.

Selecting automatic calibration option

NOTICE

The air velocity sensor must be calibrated at least once every

24 hours. Make sure that the sensor has been calibrated

before balancing takes place, as this will affect the balancer’s

results.

NOTICE

Options can be combined by summing their numbers. For

example, to calibrate as in Options 1 and 2, set CAL SETUP

to 3.

Using

Table 5

set CAL SETUP to the value that best meets

your job requirements.

If appropriate, change CAL TIMER from the default of 12

hours. This setting applies only if your choice for CAL SETUP

includes Option 4.

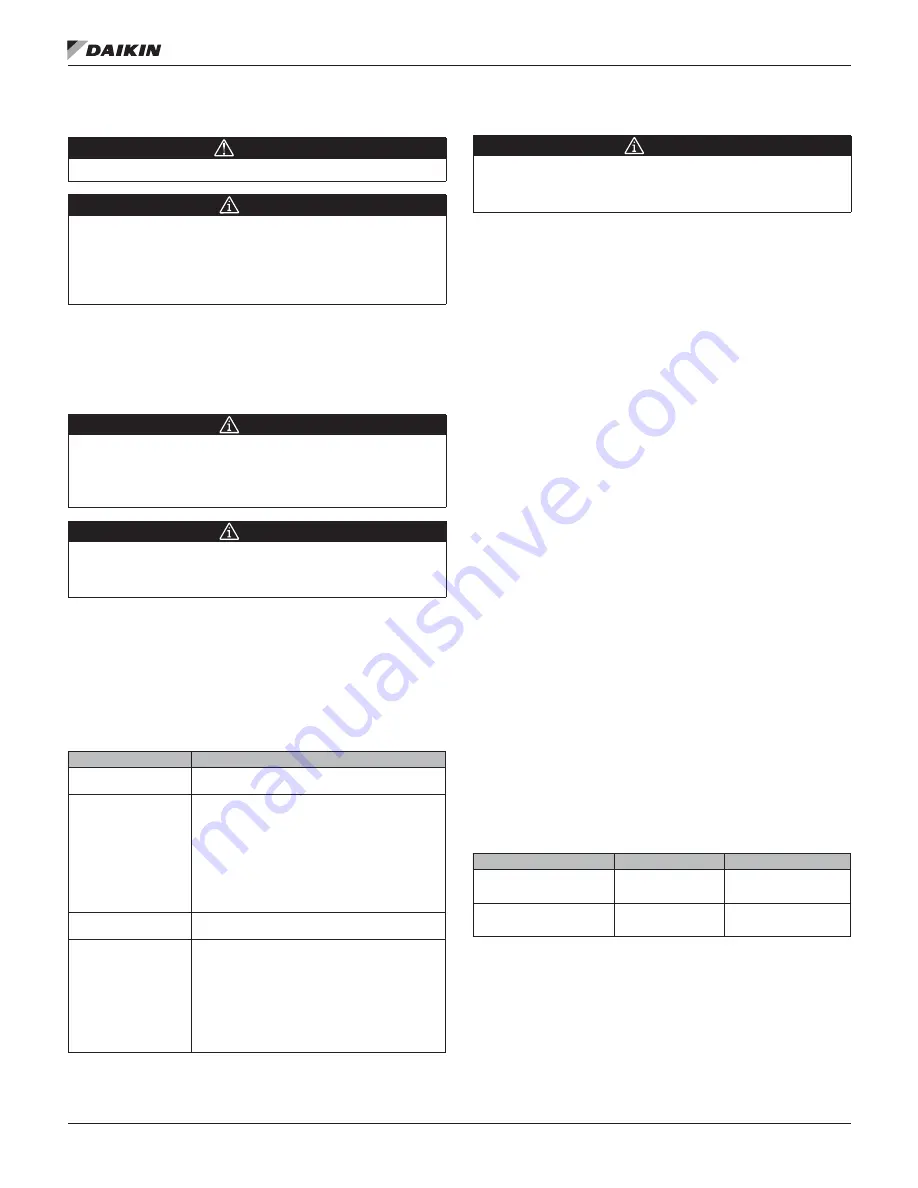

Table 5: CAL SETUP Values

CAL SETUP (Point 95)

Description

0

Calibration occurs ONLY when the point CAL AIR

(Point 94) is set to YES

1

Calibration occurs when the field panel commands

a day/night mode changeover. Actual calibration is

subject to a time delay of 0, 1, 2, or 3 minutes. This

delay is determined by the point CTLR ADDRESS

(Point 1) divided by 4. The remainder is the time

delay in minutes.

Example: If CTLR ADDRESS = 11, then the

controller will wait 3 minutes (11 ÷ 4 = 2 R3) after it

receives the day/night mode changeover command

before beginning the calibration routine.

2

Calibration occurs immediately after the override

switch is depressed.

4

(factory default value)

Calibration occurs on the time interval set in the

point CAL TIMER (Point 96).

For example, if CAL TIMER = 12, then the

calibration period is12 hours. Actual calibration is

subject to a time delay based on the value of CTLR

ADDRESS.

See the example in Option 1. This is the

recommended option when using a controller with

an Autozero Module.

Setting room temperature setpoints

NOTICE

If STPT DIAL is set to YES, do not set the DAY (or OCC)

setpoints; the value of RM STPT DIAL will be used for these

points.

•

DAY (or OCC) cooling setpoint

•

DAY (or OCC) heating setpoint

•

NGT (or UOC) cooling setpoint

•

NGT (or UOC) heating setpoint

If the room temperature sensor has a setpoint dial that will be

used, set STPT DIAL to YES. Otherwise, set STPT DIAL to NO.

Set the room temperature setpoints to the desired values

(some points are not present in certain cooling only

applications).

Set RM STPT MIN and RM STPT MAX for the minimum and

maximum allowable room temperature setpoints, respectively.

Valid values range from 55°F to 95°F (13°C to 35°C). Default

values are 55°F (13°C) for RM STPT MIN and 90°F (32°C) for

RM STPT MAX.

Setting override time

If using night/unoccupied override, set OVRD TIME to the

number of whole hours that an override should last. If OVRD

TIME equals 0 (default), then this feature is disabled.

Enabling Wall Switch

If a wall switch is used for day/night (Occ/Unocc) control,

enable it by setting WALL SWITCH to YES.

Setting Duct Area

If provided, enter the duct area (sq ft or sq m) into DUCT

AREA (and also into HTGDUCT AREA, where applicable) and

continue to

Setting flow coefficient on page 7

.

If you do not know the duct area, use

Table 6

:

Table 6: Duct Area Calculation

Area =

Round Duct

Rectangular Duct

Area in Sq. Ft.

(Dimensions in inches)

(π x R2)/144

Width × Height/144

Area in Sq. M.

(Dimensions in centimeters)

(π × R2)/10,000

Width × Height/10,000

Summary of Contents for BACnet

Page 9: ......