5 Configuration

Installation manual

15

EBLQ+EDLQ011~W1

Daikin Altherma low temperature monobloc

4P522031-1 – 2018.01

INFORMATION

▪ During the copying, both controllers will NOT allow

operation.

▪ The copy operation can take up until 90 minutes.

▪ It is recommended to change installer settings, or the

configuration of the unit, on the main user interface. If

not, it can take up to 5 minutes before these changes

are visible in the menu structure.

8

Your system is now set to be operated by the 2 user interfaces.

5.1.4

To copy the language set from the first to

the second user interface

See

"5.1.3 To copy the system settings from the first to the second

user interface" on page 14

.

5.1.5

Quick wizard: Set the system layout after

first power ON

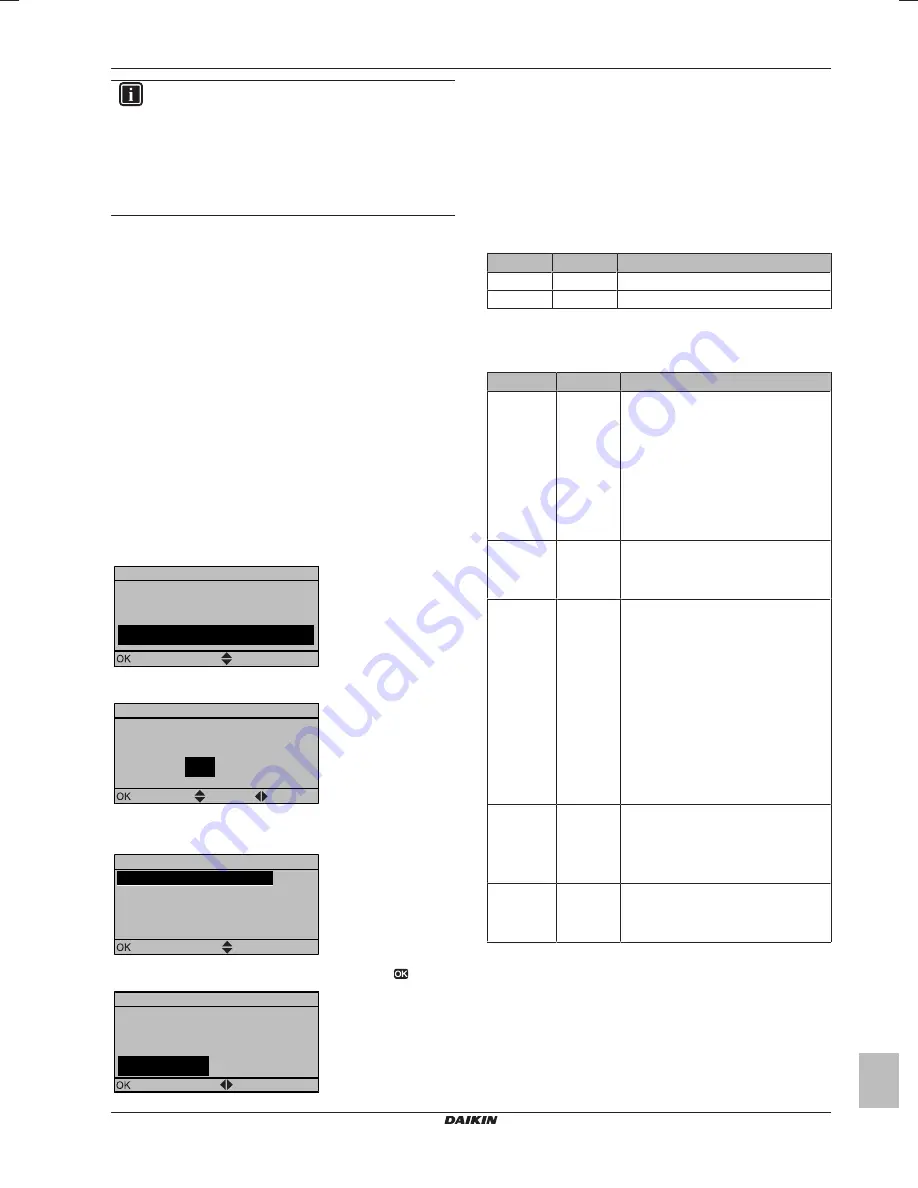

After first power ON of the system, you are guided on the user

interface to do initial settings:

▪ language,

▪ date,

▪ time,

▪ system layout.

By confirming the system layout, you can proceed with the

installation and commissioning of the system.

1

At power ON, the quick wizard starts as long as the system

layout was NOT confirmed yet, by setting the language.

Language

Select the desired language

Confirm

Adjust

2

Set the current date and time.

00

: 00

What is the current time?

Time

Confirm

Adjust

Scroll

3

Set the system layout settings: Standard, Options, Capacities.

For more details, see

"5.2 Basic configuration" on page 15

.

A.2

1

Scroll

Select

System layout

Standard

Options

Capacities

Confirm layout

4

After configuration, select Confirm layout and press

.

Confirm layout

Please confirm the system

layout. The system will

restart and will be ready for

first startup.

OK

Cancel

Confirm

Adjust

5

The user interface re-initialises and you can proceed the

installation by setting the other applicable settings and

commissioning of the system.

When the installer settings are changed, the system will request to

confirm. When confirmation is complete, the screen will shortly turn

OFF and "busy" will be displayed for several seconds.

5.2

Basic configuration

5.2.1

Quick wizard: Language / time and date

#

Code

Description

[A.1]

N/A

Language

[1]

N/A

Time and date

5.2.2

Quick wizard: Standard

Space heating/cooling settings

#

Code

Description

[A.2.1.7]

[C-07]

Unit temperature control:

▪ 0 (LWT control): Unit operation is

decided based on the leaving water

temperature.

▪ 1 (Ext RT control): Unit operation is

decided by the external thermostat.

▪ 2 (RT control): Unit operation is

decided

based

on

the

ambient

temperature of the user interface.

[A.2.1.8]

[7-02]

Number of water temperature zones:

▪ 0 (1 LWT zone): Main

▪ 1 (2 LWT zones): Main + additional

[A.2.1.9]

[F-0D]

Pump operation:

▪ 0 (Continuous): Continuous pump

operation, regardless of thermo ON or

OFF condition.

▪ 1 (Sample): When thermo OFF

condition occurs, the pump runs every

5 minutes and the water temperature

is checked. If the water temperature is

below target, unit operation can start.

▪ 2 (Request)(default): Pump operation

based on request.

Example:

Using a

room

thermostat

and

thermostat

creates thermo ON/OFF condition.

[A.2.1.B]

N/A

Only if there are 2 user interfaces:

User interface location:

▪ 0 (At unit)

▪ 1 (In room)(default)

[A.2.1.C]

[E-0D]

Glycol present:

▪ 0 (No)(default)

▪ 1 (Yes)