Operation Section

-64-

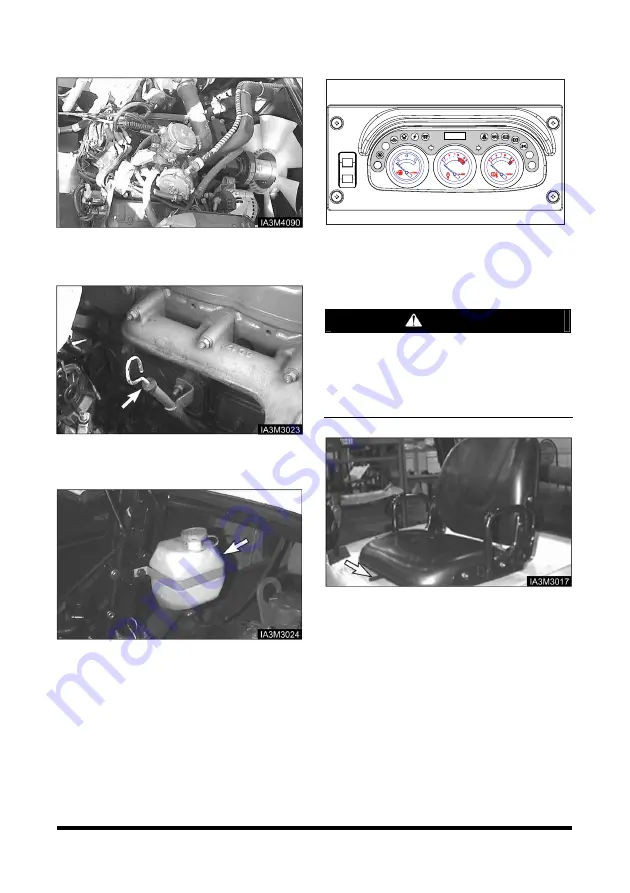

Typical Example LP-Gas Engine Truck

10.

Inspect the engine compartment for oil, coolant and

fuel leaks.

11.

Measure the engine crankcase oil level with the dip

stick. Maintain the oil level between the MAX. and

MIN., (or FULL and ADD) notches on the dip stick.

12.

Observe the engine coolant level in the coolant

recovery bottle. With the engine cold, maintain the

level to the COLD mark. If the recovery bottle is

empty, also fill the radiator at the top tank.

13.

Observe the fuel level gauge after starting the truck.

Add fuel if necessary

14.

In case of LPG truck, if needed, change LPG Fuel

Tank as the procedure of changing LP-Gas tanks in

Refueling Section.

WARNING

Personal injury may occur from accidents caused

by improper seat adjustment. Always adjust the

operator's seat before starting the lift truck engine.

Seat adjustment must be done at the beginning of

each shift and when operators change.

15.

To position the seat, PUSH the lever away from the

seat track and move the seat forward or backward

to a comfortable position.

Summary of Contents for D35S-2

Page 31: ...Safety Section 29 Lean away from the direction of fall Lean forward...

Page 39: ...General Section 37 Capacity Chart...

Page 40: ...General Section 38 Capacity Chart...

Page 41: ...General Section 39 Capacity Chart with Side Shifter...

Page 42: ...General Section 40 Capacity Chart with Side Shifter...

Page 43: ...General Section 41 Capacity Chart...

Page 44: ...General Section 42 Capacity Chart...

Page 45: ...General Section 43 Capacity Chart with Side Shifter...

Page 46: ...General Section 44 Capacity Chart with Side Shifter...

Page 47: ...General Section 45 Capacity Chart D G 50C 2...

Page 48: ...General Section 46 Capacity Chart with Side Shifter D G 50C 2...