2

Tools Required for Installation

Important Safety Instructions

When using your video equipment, basic safety precautions

should always be followed, including the following:

1. Read and understand all instructions before using.

2. Position the cord so that it will not be tripped over, pulled, or

contact hot surfaces.

3. If an extension cord is necessary, a cord with a current rating at

least equal to that of the appliance should be used. Cords rated

for less amperage than the appliance may overheat.

4. To reduce the risk of electric shock, do not disassemble this

appliance. Contact an authorized service dealer when repair

work is required. Incorrect reassembly can cause electric shock

when the appliance is used subsequently.

5. The use of an accessory attachment not recommended by the

manufacturer may cause a risk of fire, electric shock, or injury to

persons.

Pre-Installation

Prior to Retrofit installation, you will need to run a CAT5 or

CAT5e network cable from the motor end of your screen to

the area in which your computer will be located. THE CAT5

CABLE IS NOT PROVIDED. The length of the CAT5 cable cannot

exceed 200 feet. See Pre-Installation of ViewShare Screen and

Roller Assembly and Camera and Speakerphone Installation

sections for additional details on CAT5 cable connections.

NOTE:

It requires at least two people to install a ViewShare

Retrofit.

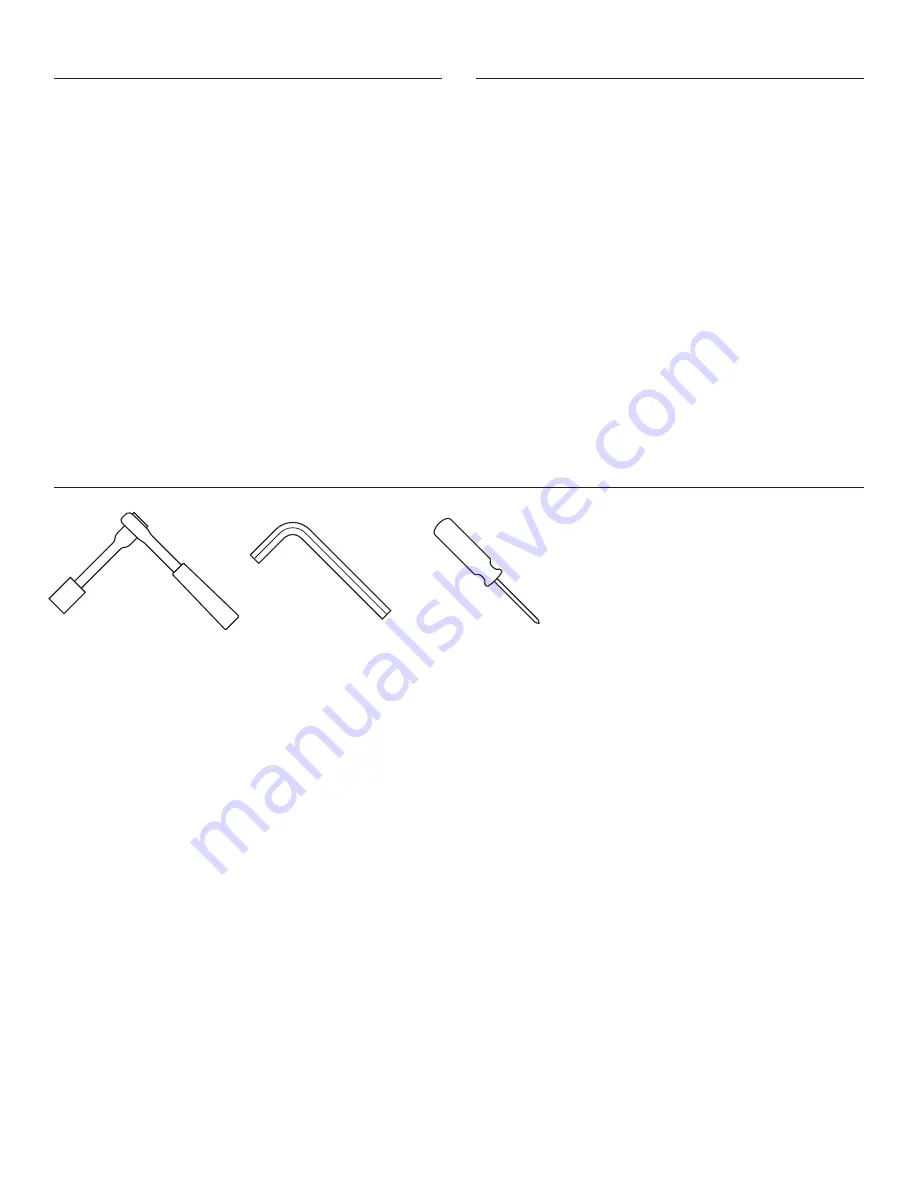

7/16“ Socket Driver

with 6" Extension

1/8” Hex Key

(included)

#2 Phillips Screwdriver

Summary of Contents for ViewShare

Page 1: ...INSTRUCTION BOOK FOR ViewShare Tensioned Advantage Electrol Retrofit ...

Page 18: ...18 ...

Page 19: ...19 ...