6-8

520 Express Series

520 Express Series

3. Use one of two methods to determine

when the proper amount of oil has been

delivered to the engine.

a. Pre-measured Method – this method

requires the operator to set aside a known

quantity of oil prior to filling. For example,

if the engine requires 22 quarts of oil, the

operator may want to pump from a 5

gallon container, adding two additional

quarts as the container empties.

b. Timed Method – the timed method is

used when pumping from a container of

unknown capacity, or a reservoir. The flow

of oil through the system varies primarily

with the viscosity and temperature of the

oil. Under normal conditions 75°F to 85°F

(24°C to 29°C), the system pumps four

quarts of 40 weight oil (one gallon) in

approximately 90 seconds.

NOTE

Models 946DB or 946DBT pump

eight quarts (two gallons) of 40

weight oil in approximately 90

seconds. Filling time is a function of

several factors, including the oil

temperature and weight. Oil (40

weight) at 85°F (29°C) pumps

approximately 20% faster than the

same oil at 75°F (24°C).

Fresh oil

should be 75°F (24°C) or warmer

before pumping!

FILLING THE ENGINES

1. Loosen the oil filler cap on the engine or

remove the dip stick to allow air to enter

the crankcase.

2. Insert the PVC wand of the drain/fill hose

into a container of fresh oil.

3. Release the fail-safe lock device on the

pump/motor unit valve handle and direct

the arrow-shaped tip to PORT ENGINE.

4. Flip the pump motor control switch on

the system to the FILL position. The

pump will start immediately and you will

observe the oil moving through the clear

tubing toward the pump/motor unit. You

should hear a noticeable change in the

sound (speed) of the pump motor when

the oil enters the pump.

5. Continue to operate the pump until a

measured amount of oil has been

pumped into the engine’s crankcase.

Fresh oil is pumped at the rate of about

one gallon each 90 seconds.

NOTE

Models 946DB or 946DBT pumps

fresh oil at a rate of two gallons per

90 seconds.

6. Flip the pump motor control switch to the

OFF position when the oil pan nears its

filled capacity and check the proper oil

level with the engine’s dip stick (or other

measuring device supplied with the

engine). If filling is completed, place the

fail-safe switch in the OFF position.

NOTE

If you have overfilled an engine, you

may simply flip the motor control

switch to the DRAIN position for a

few seconds and remove the excess.

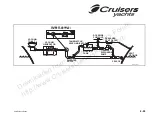

Davit Lift System

The “Davit Lift” system should NOT be

bonded to the ship’s bonding system. Zinc

anodes must be placed on BOTH main

tubes of the lift. Any portion of the system

that extends below the waterline and comes

in contact with the water should be painted

with an appropriate bottom paint.

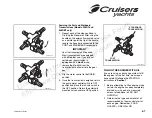

Helm Seat

The helm seat can be adjusted fore and aft.

The front of the seat can be positioned as a

“leaning post.”

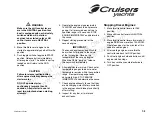

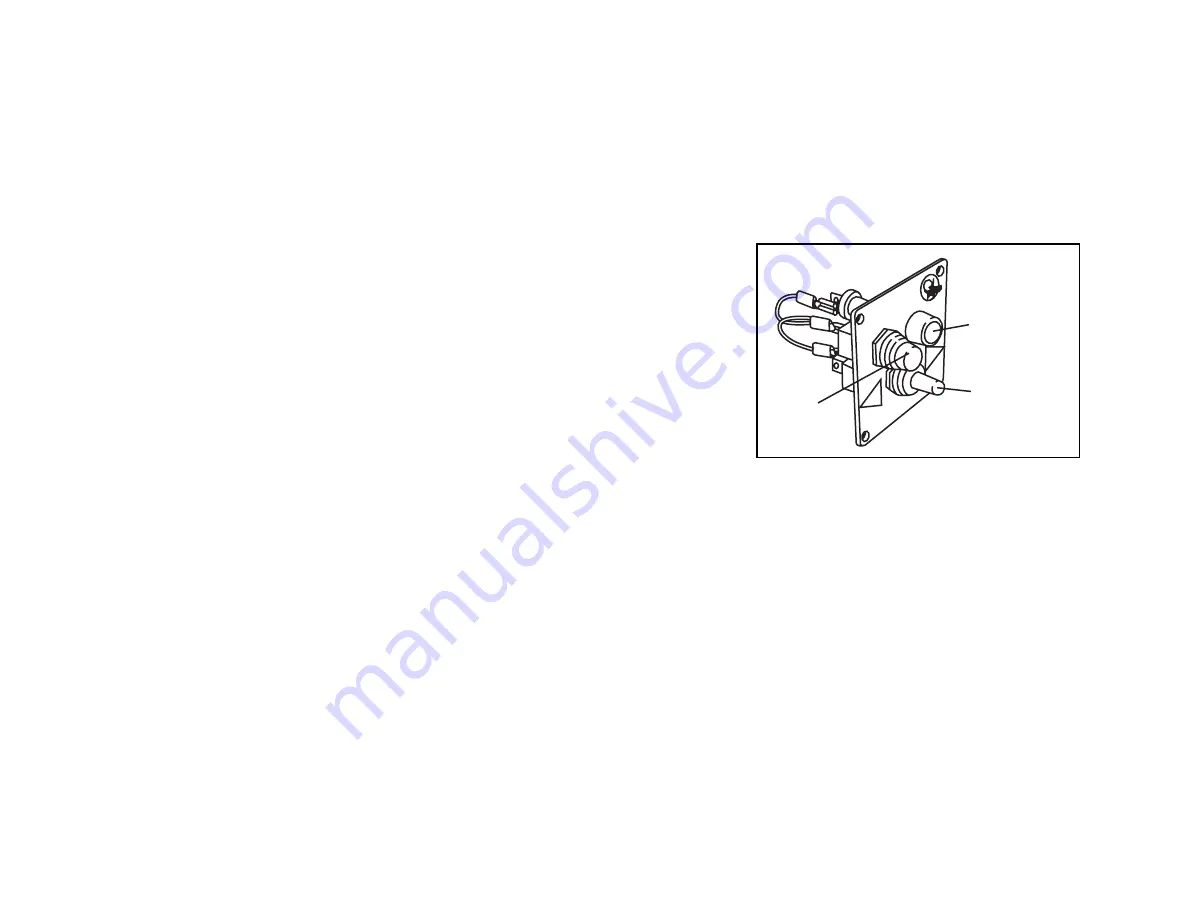

ON / OFF

KNOB

INDICATION

LIGHT

CONTROL

SWITCH

CSR173-48

Downloaded

from

Cruisers

Owners

Forum

http://www.CruisersOwnersForum.com