K. FINAL ROTARY LIMIT SWITCH ADJUSTMENT

After the run speed, creep speed and ACCEL & DECEL

have been adjusted, the fi nal limit switch settings can be

made.

(a) Actuate the operator controls and adjust the

rotary limit switches (LSO & LSC) to stop the

door in the full open and closed positions.

(b) Actuate the operator and adjust the rotary limit

switches (LSCO & LSCC) to initiate the creep

mode at the desired time. Keep in mind that the

operator only travels in creep mode as long as

the cam lobe is depressing the snap switch.

Note: The length of time the operator is running in creep

mode must be long enough to allow for it to dynamically

brake from run speed to creep speed plus the desired

length of time the operator is traveling under creep

mode. If the DECEL time is set for too long, the creep

mode may be adversely affected.

(c) After adjusting LSCO & LSCC check the travel of

the door. LSC & LSO may need to be re-adjusted.

(d) Activate the operator to open and close the door

several

times

and

fi ne tune the limit switch

settings.

(e) Close limit switch cover and tighten down screw

clamp.

(f) Periodically the limit switches may require

adjustment. This is especially evident during the

initial few weeks after start up due to chain

stretch and wear in.

L. FINAL ADJUSTMENTS & CHECKS

(1) Make a fi nal check of operator, Chain Tensioner,

sliding door hardware, sag roller(s) and idlers. It is

extremely important that the operator be run several

times to check chain alignment. Make corrections as

needed.

3. MAINTENANCE

A. GENERAL

To insure that the electric operator is ready for operation

at all times, it must be inspected systematically which will

preclude serious damage or failure. Proper adjustment

and lubrication must be maintained and checked as

recommended below.

B. LUBRICATION

(1) LUBRICATION FOR GEARMOTOR

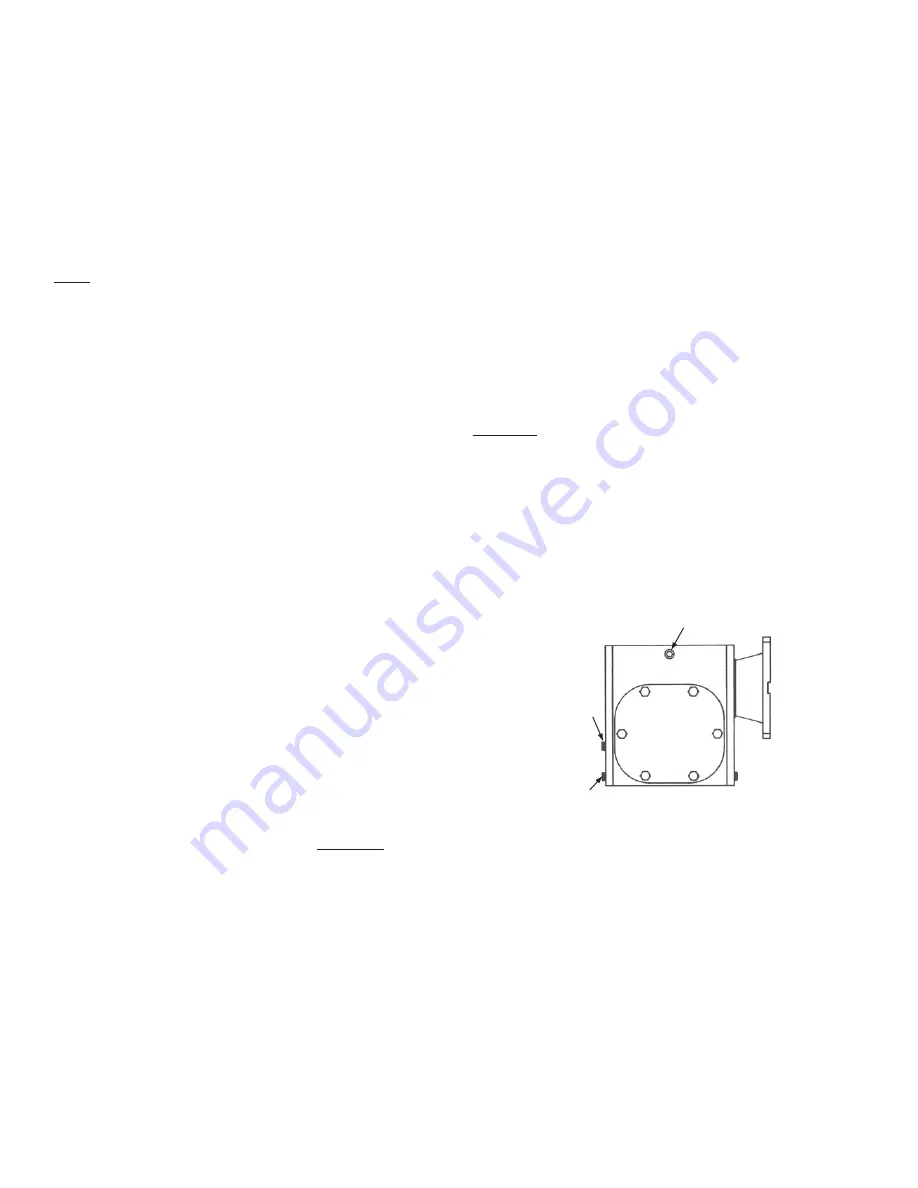

(a) Figure 16 shows the proper location of vent, oil

level, and drain plugs.

(b) The drive unit is pre-lubricated and shipped with

Mobil "SHC 634" synthetic lubricant. This oil is a lifetime

lubricant rated for operation in ambient temperatures

ranging from -40°F to +125°F.

(2) Every 900 cycles, where one cycle consists of

opening and closing of the door, or every 3 months

whichever comes fi rst, clean and lubricate the chain with

a SAE lubricant as required for ambient temperature.

C. PREVENTIVE MAINTENANCE

To prevent damage or improper operation, the following

inspections should be let made at least EVERY 6

MONTHS.

(1) Check oil level by removing the oil level plug. Oil

should be up to the bottom of the plug hole.

(2) Check tension of chain.

(3) Check all electrical components and wiring for

tightness.

(4) Check clutch to see that it doesn’t slip under

normal

operation.

(5) Check all bolts and nuts for tightness.

VENT PLUG

OIL LEVEL

PLUG

DRAIN

PLUG

Figure 7.

A. TO ORDER REPLACEMENT PARTS

(1) SEND IN SERIAL NUMBER OF ELECTRIC

OPERATOR.

(2) SPECIFY the number of pieces needed.

(3) Order by part number and name of part.

(4) State whether to ship by freight, truck, parcel

post, or air express.

(5) State whether transportation charges are to be

prepaid or collect.

(6) Give name and address of the person or

company to whom the parts are to be shipped.

(7) Give name and address of person or company to

whom the invoices to be sent.

4. PARTS

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

www.crown-industrial.com Email: [email protected]

G-2001

6