11

PREVENTIVE MAINTENANCE

For better functioning and durability of your vacuum pump, some procedures are needed.

Preventive maintenance correspond to the

accomplishment of all procedures below

.

PERIODICITY

MAINTENANCE

DAILY

Vacuum pump internal cleaning:

It is recommended that a specific product for this purpose be used, for example, a

detergent which is suitable to disinfect and dissolve residues inside the vacuum

system, for it will reduce the need of cleaning and keep the suction capacity

through duct clearance. To perform this kind of cleaning, proceed according to the

cleaning product manufacturer’s instructions.

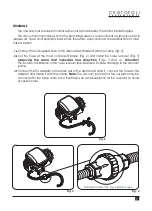

Residue filter cleaning:

Open the filter cover by turning it counterclockwise (Fig. 10, page 9), remove-it and

discard the residue in appropriate place. Wash the cover of the residue filter and

filtering element, verify if the gasket inside the cover is properly placed, and

reposition the residue filter. If the gasket is damaged, replace-it. To buy extra filtering

elements, consult your local Cristófoli authorized dealer.

ATTENTION! Never forget to

reposition the filtering element of the residue filter. Small fragments are enough

to damage the internal components of the vacuum pump.

MONTHLY

External cleaning:

Unplug the power cord and perform cleaning with a feather duster or a soft cloth,

slightly moistened with water and biodegradable neutral detergent, after it, clean

with a cloth, moistened with 70% alcohol and 1% peracetic acid. Never use

solvents or petroleum derivatives. Verify the openings at the bottom of the motor, if

there’s dirtiness accumulation on it, perform cleaning.

YEARLY

General revision and flow limiter regulation

(we recommend that this procedure

be performed by an authorized technical assistance):

Unplug the power cord and close the water supply valve. Remove the hose

connected to the water supply valve. Remove the filtering screen and take the flow

limiter out of the water inlet with a needle nose plier. Rotate the tip of the flow limiter

counterclockwise, taking care not to damage the internal rubber disc. After

removing, wash the parts below running water. When mounting it, take care not to

press the rubber disc. Reposition the set back to the valve. Reconnect the hose to

the water inlet. Turn on the vacuum pump and make the measuring test again.

Measuring test (water consumption):

Disconnect the hose from the drain exit of the

vacuum pump. Use a measuring cup with ml (millilitre) scale and a stopwatch.

Activate the vacuum pump, wait for 3 to 5 minutes, until the flow of expelled water

stay constant. Place the measuring cup at the vacuum pump water exit and collect

the expelled water for 1 minute. After this time, observe if the amount of expelled

water is 160 ml. If the result taken is different from the indicated value, perform the

procedure again.

Table 4

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N

M A N U A L

Summary of Contents for SuperGap Evolution 2

Page 16: ......