Responsible Technician

Eduardo Luiz Soppa

CREA-PR: 109201/D

MANUFACTURER

Cristófoli Equipamentos de Biossegurança Ltda.

Rod. BR 158, nº127 - Campo Mourão - PR - Brasil

CEP 87303-650

CNPJ 01.177.248/0001-95 - Inscr. Est. 90104860-65

Website: www.cristofoli.com - e-mail: [email protected]

4

The complete reading of this manual is indispensable for safe use of the equipment and

preventive maintenance orientation. The owner is responsible to perform the adequacy of the

electrical, hydraulic, suction and drainage systems.

The SuperGap Evolution vacuum pump must be handled by professionals, well aware of

the equipment operation.

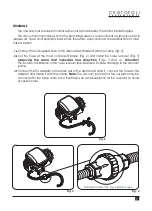

Box content:

- 1 Supergap Evolution 2 Vacuum Pump. - 1 noise reducer.

- 1 residue filter.

- 4 leveler glides with nuts and washers.

- 2 corrugated hoses (1,5 m).

- 3 clamps.

- 2 R/L adapters.

- 1 hose for water inlet.

- 1 manual.

INTRODUCTION

This equipment was developed for suction of fluids and residues from odontological

treatments or surgeries.

INTENDED USE

RECOMMENDATIONS AND WARNINGS

Read all instructions of this manual before using your SuperGap Evolution. The incorrect use

may result in malfunction and/or accidents.

For your safety, when performing any kind of maintenance, remember to unplug the power

cord and use PPE (Personal Protective Equipment).

Do not allow patients, especially kids, to get close to the equipment.

Never use your vacuum pump without water.

During the vacuum pump operation, it’s perfectly normal to hear noises, which are part of

the proper functioning of the equipment. Cristófoli is not responsible for accidents that might

occur due to jolts caused by the noises produced by SuperGap Evolution.

Do not use the vacuum pump as a water pump.

Do not place any kind of fabric under the vacuum pump, for it makes difficult the

ventilation, causing overheating and damage to the equipment.

Never move or drag the vacuum pump by the power cord or hoses, keep those parts away

from heat or sharp corners.

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N

M A N U A L

Summary of Contents for SuperGap Evolution 2

Page 16: ......