- 32 -

- 33 -

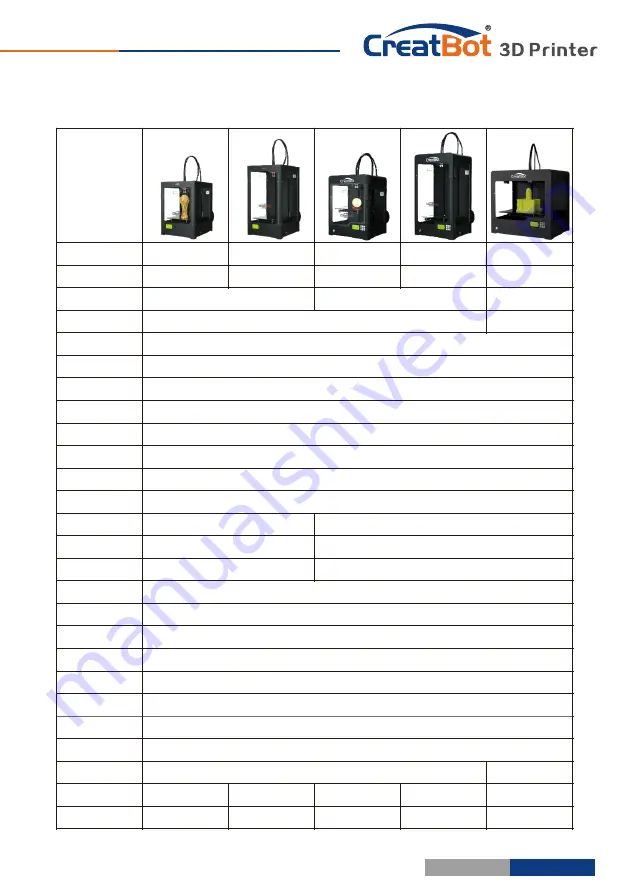

Specifications

Model

DM

DM

Plus

DX

DX

Plus

DE

Build

Size

250

*

250

*

300

250

*

250

*

450

300

*

250

*

300

300

*

250

*

520

400

*

300

*

300

Nozzles

Single

/

Dual

Single

/

Dual

/

Tris

Single

/

Dual

Diameter

0

.

3~1.0mm (other

sizes

can

be

customized)

0

.

3

~

1

.

5mm

Temperature

250

℃ (

300

℃

extruder

update

supported

)

Hot

bed

120

℃ (

can

be

closed

after

certain

layers

)

Min

.

Layer

0.04mm

(

less

than

0

.

04

is

not

recommended)

Accuracy

X

、

Y

、

Z axis 0

.

01mm

Print Speed

120mm

/

s

(

inner

/

outter

,

top

/

bottom

,

fill

,

first

layer

speed

can

be

set

separately

)

Travel

Speed

200mm/s

Materials

PLA

、

ABS

、

PVA

(

dissolve

)

, Nylon

,

PS

and

so on (<350

℃

)

Fila

.

Diameter

3

.

0mm (1

.

75mm optional

)

Keypad

No

Yes

(

nine

key

)

Auto

Turnoff

No

Yes

(

pwr

manager

+

relay

)

Continue

Play

No

Yes

(

Power

outage

,

lower

plate

and

save

data

)

Fila

.

Check

Yes

(

pause

printing

when

filament

finish

,

and

lower

platform

)

Adju

.

Head

Yes

(

height-adjustable-nozzles

)

OS

Windows, Linux, Mac OS, OSX

Languages

Chinese

,

English

, French,

multi

-

language

Software

CreatWare Muti

-

language

File Format

STL, OBJ, GCode, Amf

Chipset

Atmega 2560-16AU (AVR

8 Bit 16MHz

,

256KB Flash)

Display

128*64 monochrome

multi

-

language

(

support

color

TFT

)

Pwr

Supply

110~220V 360W

Double

Pwr

Dimension

370*420*530

370

*

420

*

680

420

*

380

*

570

420

*

380

*

790

590

*

430

*

570

Weight

25 Kg

30

Kg

28 Kg

35 Kg

45 Kg

Frequently Asked Questions

not over 120℃, and you can close the bed above 100mm.

3. The model not stick on the platform ?

Please

paste

masking

paper

or

Kapton

on

the

platform

,

or

the

nozzle

is

too

far

away

from

the

platform, or the bottom of the model is not flat.

4

.

No

or

less

silk

coming

on

the

first

layer

?

The

distance

between

nozzle

and

platform

is

too

small

,

or

the

filament

has

not

been

sent

to

the

nozzle

.

5. Why nozzle is not spit silk ?

The

filament

is

not pressed or too tight, or print temperature is too low, or the

filament feeder not working.

6

.

How

to

prevent

model

become

warped

?

Increase hot bed temperature or use Kapton, or change platform adhesion

type to Raft, or cover the baffle, or reduce indoor ventilation.

7

.

How

far

from

nozzle to platform appropriate ?

Distance

should

be

0

in

theory

,

but

there

is

no absolute flat platform, so the

distance -0.1mm. Finally, with the actual printing effect as the

standard, too close will lead to a silk blocked, too far will cause the model not

stick on the platform.

8

.

How

to

determine

whether

the

temperature

is too high ?

PLA

temperature

is

too high will appear liquefaction

,

ABS

will

be

the

carbide

,

that

will

block

the

nozzle

.

9

.

What

reasons

will

causing

nozzle

blocked

?

Filament are impurities or print environment dust too much, bad of thermal

conductivity between the nozzle and the heating block.

10

.

Model

surface

is

loose

with

crack

?

The

layer

is

too

high

or

the

printing

speed too fast, nozzle temperature too

low or filament press nut too loose, or filament is wrapped.

11

.

How

to

a

small

model

?

Multiple

the

model

,

and

print them at a time.

12

.

Dual

color

model

not

aligned

?

Adjust

offset

of

second

nozzle

in

machine

settings

.

13

.

Dual

color

model

color

interference

?

Align two nozzle in vertical direction

14

.

There

is

too

much

silk

drag

on

the

model

?

Please

enable

filament retraction, and specified proper retract speed, and

distance, the retract distance should not less than 4mm, and the speed not

less than 10mm/s.

Printing

Troubleshoot