11

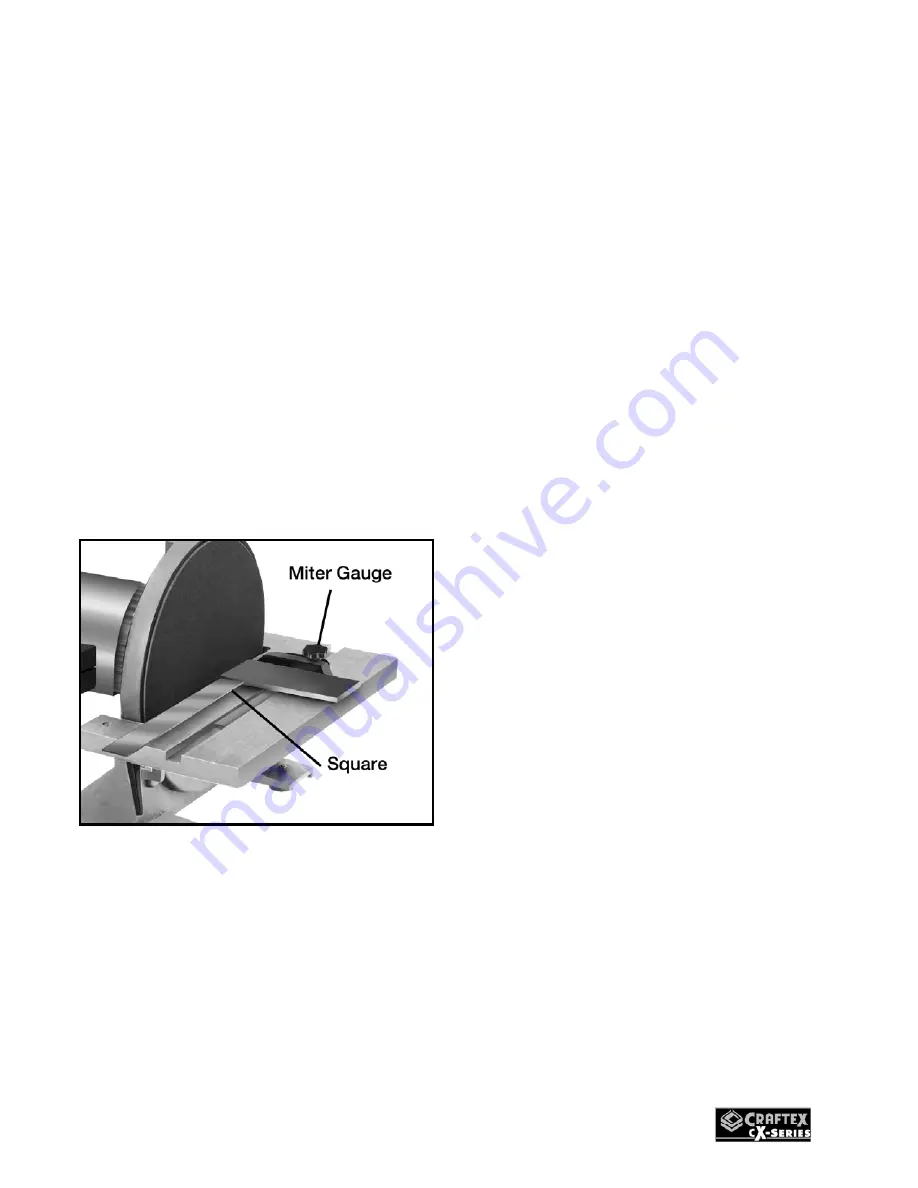

MITER GAUGE

The miter gauge needs to be adjust

perpendicular to the face of the table slot

when it is mounted to the table slot.

To adjust he miter gauge:

Position the miter gauge on the table and

mount it to the table slot.

Loosen the adjusting screw on the miter

gauge and make it flush with the edge of

the square.

Loosen the screws securing the angle

pointer and adjust the pointer to 0° mark.

Retighten the screw that secures the angle

pointer.

Figure-6 Adjusting miter gauge

ATTACHING SANDPAPER

The CX506 comes with a 12" sanding disc,

attached to the cast iron disc platen with its

adhesive backing.

To attach the sandpaper:

Disconnect the cord from the power source.

Peal off the old sandpaper, and clean the

platen disc surface and make sure it is dry.

Peel off the protective layer on one-half of

the sandpaper disc and fold it against the

remaining half.

Slip the half with protective layer between

the table edge and the platen disc.

Position the sandpaper on the platen disc

so that it is centered and press it so that the

exposed half is sticking on the platen disc.

Rotate the platen disc with hand so that the

half with protective layer is above the table.

Peel off the remaining protective layer and

press to attach the sandpaper to the platen

disc.