Standard Recom m ended Procedure 003-1002-BEN | Issue 4 | January 2019 | Page 18 of 26

Step 5:

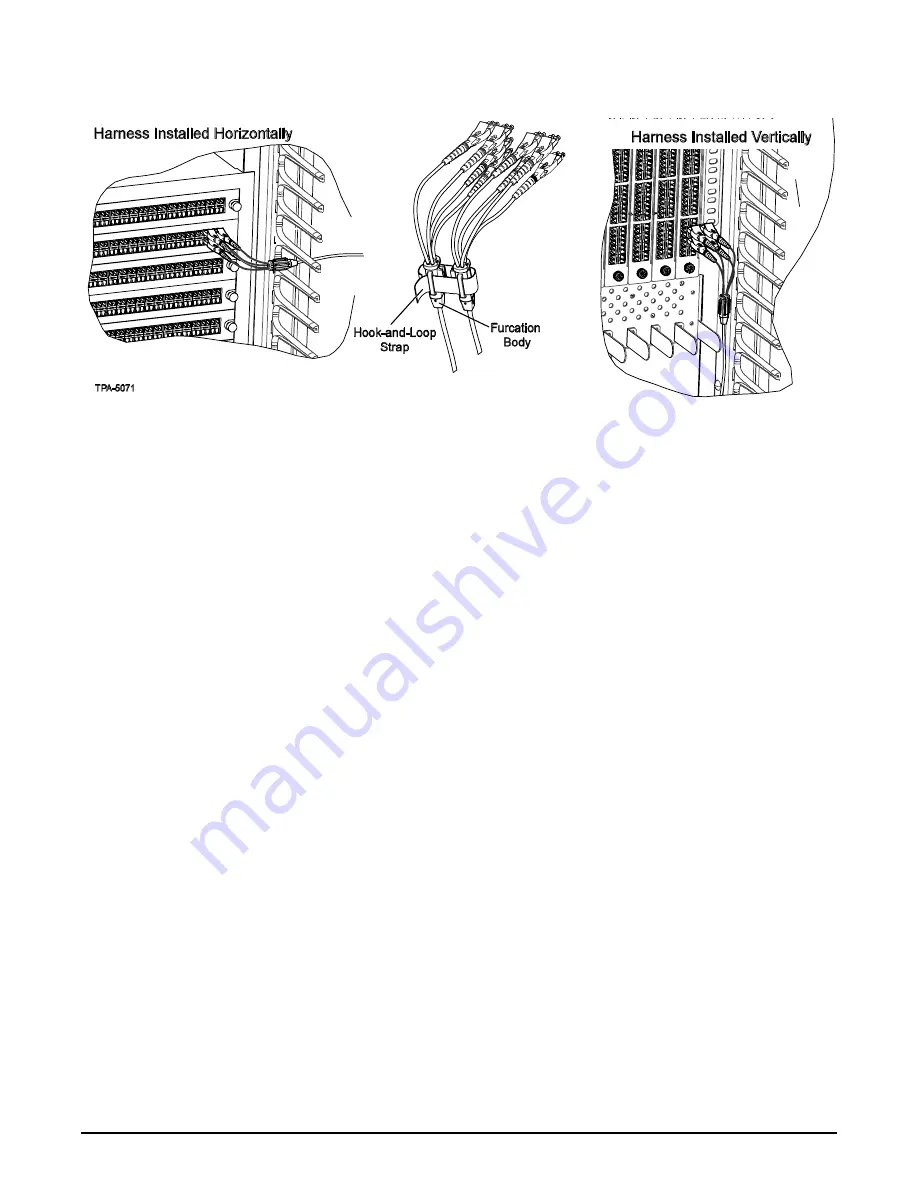

Clean the connectors at the end of the harness, jumper, or trunk and mate in the electronics

equipment as illustrated in Figure

26 per instructions provided w ith that equipment or according to

your installation plan.

Figure

26 — Typical Harness Con

gurations

5. Recordkeeping

Detailed and accurate recordkeeping enables users to logically “ map”

bre terminations w ithin the data center

from local equipment to remote equipment . It is recommended that users employ labelling guidelines outlined

in ANSI/ TIA-606 for mapping the netw ork. Guidelines below provide an analogous solution in accordance

w ith this standard for labelling to be used w ith the EDGE8™ solution. Additions in the suggested coding are

accounted for to identify housing/chassis trays and modules.

5.1 Hardw are

Labelling

•

Hardw are components come pre-labeled for identi

cation and promote a consistent labelling

schem e.

•

Users must provide their own label maker and media for the frame or cabinet and hardware.

•

Labelling is best supported w ith use of adhesive backed label makers w ith media up to 1.27 cm

(0.5-inch) in height.

•

M odule positions w ithin each chassis tray are identi

ed by alphabetical characters A through F

from left to right.

•

M odules or MTP

®

panels come assembled w ith adapters and silkscreened w ith Fiber and/ or Port

ID.

•

Housing/ chassis comes equipped w ith a label card that is easily removable from the inside of the

front door and requires no additional fastening to remain in place. This label may be written on,

but use of a label maker is better.

•

Label card supports adhesive-backed label media and printed labels may be easily adhered or

removed for moves, adds, and changes.

Hardw are labelling involves a

ve-step process that identi

es the local and remote site. Use the suggested code

in Figure

27 and the follow ing steps to map your location. User should print and record the remote location on

t he provided label card.