Technical Support Manual – 03/2017 Rel. 0

Page 36

4. MACHINE CALIBRATION

To operate properly, the machine must be calibrated. Calibration allows storing the mechanical and electrical parameters specific to

each machine so as to provide the best balancing results.

4.1 When to carry out machine calibration

Table T4.1 lists the cases in which machine calibration should be carried out.

Table T4.1: Conditions for carrying out machine calibration

Condition

Status

Who must perform it

When the machine is installed at the final user.

Mandatory

Technical Service

When the electronic circuit board is replaced.

Mandatory

Technical Service

When a mechanical part linked to the pick-up signals (pick-up, pick-

up compression springs, suspension unit + shaft) is replaced.

Mandatory

Technical Service

When the pick-up compression springs adjustment are modified.

Mandatory

Technical Service

When the encoder disc is replaced.

Mandatory

Technical Service

When a different motorbike adaptor is used since the last

calibration for MOTO Wheel Type.

Mandatory

Final user and/or Technical Service

When the machine doesn’t show accurate results for balancing.

Recommended

Final user and/or Technical Service

When there are wide and constant variations due to environmental

humidity and temperature (for example seasonal changes).

Recommended

Final user and/or Technical Service

The machine requires two independent calibrations:

•

Calibration for the CAR/SUV Wheel Type (calibration is the same for both types of wheel);

•

Calibration for the MOTO Wheel Type (wheels for motorbike).

It is not mandatory to perform both calibrations. If the user exclusively uses the machine to balance auto-vehicle/off-road wheels

(CAR/SUV) he must perform only calibration for the CAR/SUV wheel type.

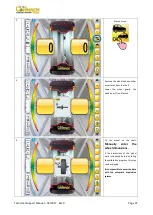

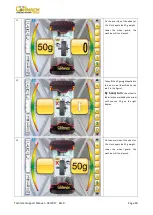

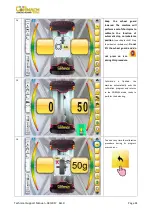

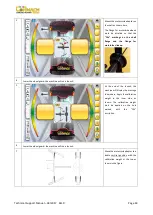

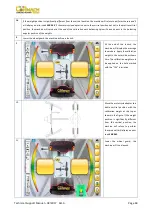

4.2 Machine calibration for the CAR/SUV Wheel Types

Calibration for the CAR and SUV Wheel Types is the same. To perform machine calibration, you must first provide for the following

material:

•

A balanced wheel (complete with rim and tyre) with steel rim and with the following dimensions: 14” ÷ 16” diameter: 5”

÷ 5.5” width. Do not use wheels with aluminum rims.

•

A 50-gram weight (preferably made of Iron or Zinc).

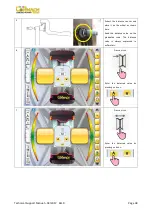

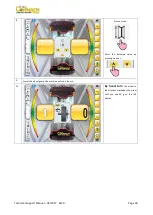

To calibrate the machine, proceed as described below:

Ph.

1

Summary of Contents for TOUCH MEC 1000 SONAR

Page 1: ...WHEEL BALANCERS TOUCH MEC 1000 SONAR TECHNICAL SUPPORT MANUAL UK...

Page 2: ......

Page 53: ......