If the compressor is equipped with a liquid trap not

manufactured by Corken, make sure it is adequately

sized; otherwise, it may not be able to remove the liquid

entrained in the suction stream.

Corken’s liquid trap provides the most thorough liquid

separation (see figure 1.4) and is American Society of

Mechanical Engineers (ASME) code stamped. It contains:

• Manual drain valve.

• Relief valve designed according to the ASME code to

protect the vessel

• Pressure gauge with isolation needle valve

• Two (2) level switches: one for alarm and one for

shutdown. In some cases, the alarm switch is used to

activate a dump valve (not included with trap) or sound

an alarm so the operator can drain the trap using the

manual drain valve at the bottom of the trap.

• This trap also contains a mist pad. A mist pad is a mesh

of interwoven wire designed to remove fine liquid mists.

NOTE: The liquid level switches MUST be removed

from the trap before grounding any welding devices

to the trap or associated piping . Failure to do so will

damage the switch contacts!

2 .5 Driver Installation and Flywheels

Corken compressors may be driven by either electric

motors or internal combustion engines (e.g. gasoline,

diesel, natural gas, etc.). They are usually V-belt driven.

The fly wheel has dual purpose it is sheave for the

V-belts and for compressor speed variation reduction.

The electric motor wiring is extremely important and

must be done by a competent electrician. Low voltage

or improper wiring of the motor will result in expensive

consequences. If there is a low voltage problem, call the

power company.

Humid climates can cause problems with explosion

proof motors. Explosion proof and TEFC motors are

designed to expand and contract due temperature

changes. This allows air to enter and exit the enclosures.

The moist air inside the motor can condense and if

enough water accumulates, the motor will fail.

To prevent this two method can be followed

• Make a practice of running the motor at least once

a week on a bright, dry day for an hour. During this

period of time, the motor will heat up and vaporize the

condensed moisture.

• Motor space heaters are recommended which need to

be powered at all times to vaporize the any moisture.

NOTE: No motor manufacturer will guarantee their

explosion proof or totally enclosed (TEFC) motor

against damage from moisture .

Drivers should be selected so the compressor operates

between 400 and 1200 RPM. The unit must not

be operated without the flywheel or severe torsional

imbalances will result causing vibration and a high

horsepower requirement. The flywheel should never

be replaced unless it has a higher wk2 value than the

flywheel supplied from factory.

For installation with engine drivers, thoroughly review

instructions from the engine manufacturer to assure the

unit is properly installed.

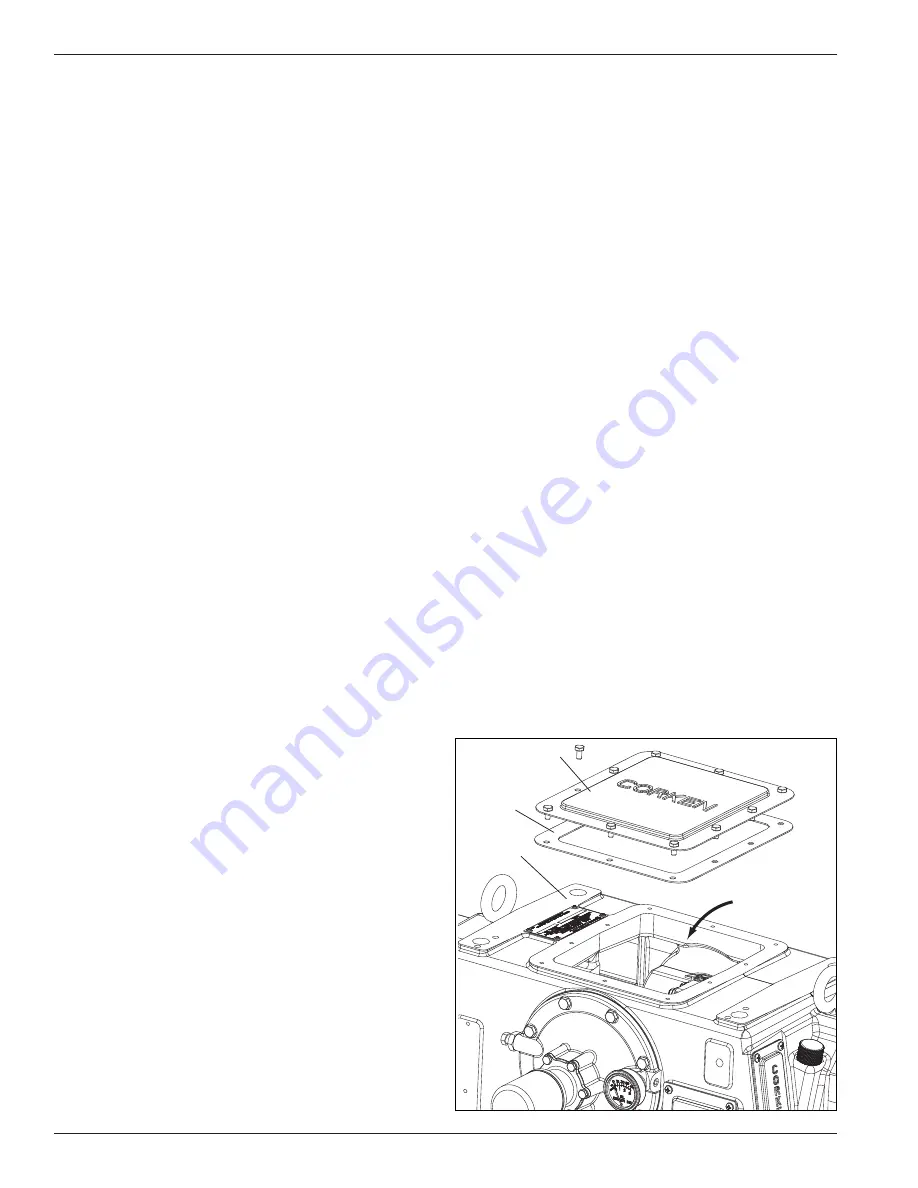

2 .6 Crankcase Lubrication

The crankcase was drained before shipment. Before

starting the machine, fill the crankcase to the full mark

on the oil bayonet and not above. To ensure proper

lubrication of the crankcase parts, the crankcase should

be filled through the crankcase inspection plate (see

figure 2.6A for the proper oil filling location).

General Notes on Crankcase Oil

Corken gas compressors handle a wide variety of

gases in a multitude of operating conditions. They

are used in all areas of the world from hot dusty

deserts, to humid coastal areas, to cold arctic climates.

Some compressors may be lightly loaded and run

only occasionally, while others may be heavily loaded

and operate 24/7. Thus, no single crankcase oil or

maintenance schedule is right for every compressor.

Availability of brands and grades of oil can vary from

one location to another. These factors can make it

Figure 2.6A

Inspection plate

Inspection plate

gasket

Crankcase

Fill crankcase

through this opening

8