Trouble Shooting

52

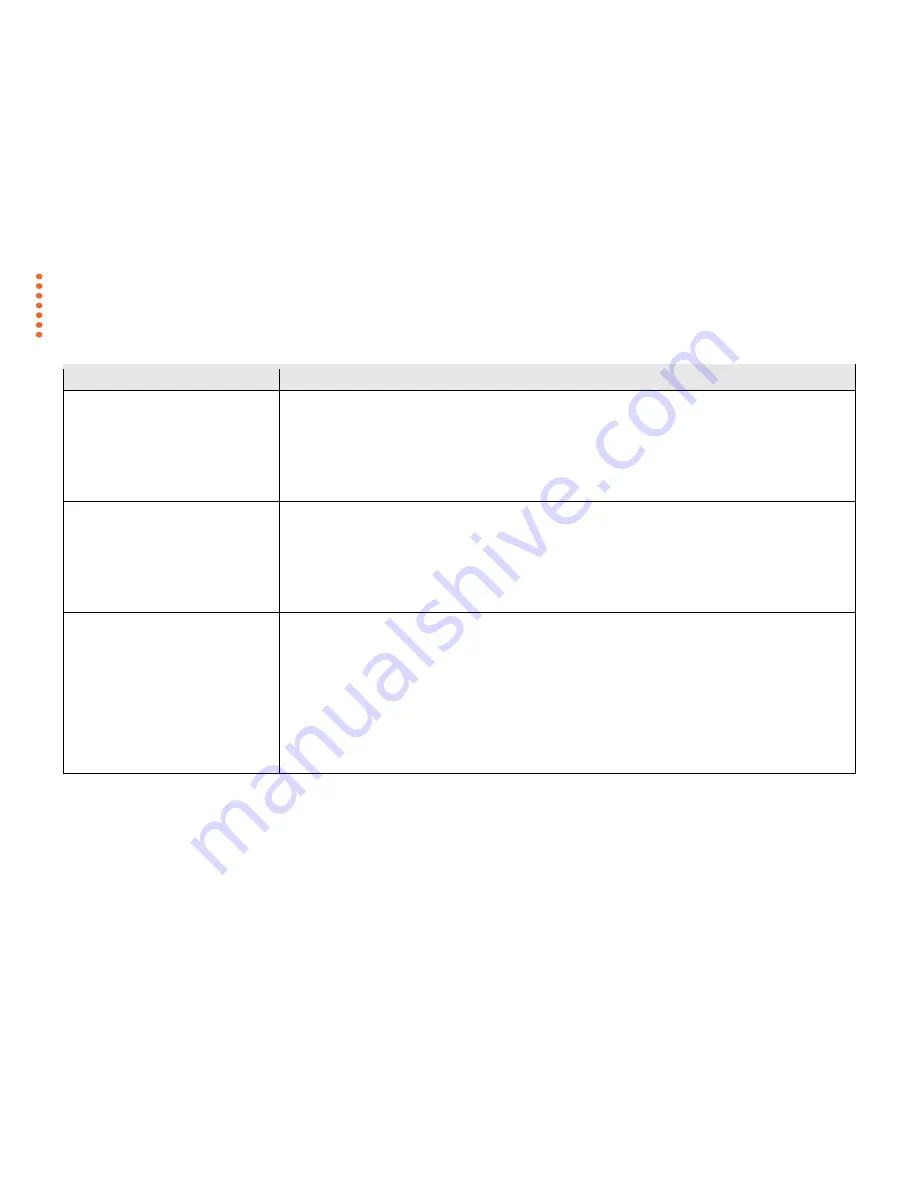

Problems Related to the Scanning Results

Problem

Possible Causes and Remedies

Entire image is not scanned

1. Check in your scanning application that your size settings are either for Auto detection or correspond to the size of the whole

original.

2. Check in your scanning application that you are loading the original correctly. Be sure to align the center of the original with

the scanner’s center arrow marking.

Stitching problems – Image sections

misaligned (at points between the sensors

-overlapping pixels)

1. Remove the original from the scanner and calibrate the scanner.

2. The Alignment Calibration includes correction of stitching errors.

3. If the problem persists after calibration – Your sensors may need readjusting. Summon your technical service provider.

One or more thin vertical lines (in the

direction of paper feeding) show up in the

scanned image, but not in the original

drawing.

This is often caused by an unclean glass plate. Even a single spec of dirt in the wrong spot on the glass plate can apply a streak

along your entire scan. To remedy:

1. Clean your glass plate and rollers as described in this users’ guide.

2. Most dirt on the glass plate is introduced by the documents that are passed against it. Wipe clean the document with a dry

lint-free cloth before feeding the document into the scanner.

3. If the problem persists after cleaning, start WDEsystem and calibrate the scanner. The scanner may have memorized dirt

specs and you need to recalibrate after dirt-removal.

4. If the problem persists after cleaning and calibration –Check the glass plate for scratches. A damaged glass plate should be

replaced. Obtain a new glass plate from your service provider. Follow the steps in the user’s guide to replace the glass plate

with a new one.

5. A damaged calibration sheet can also cause streaks. Obtain a new sheet and recalibrate the scanner.