19

EC3-680-3 February 2017

Order # 5041558-0 & 5041679-0

SECTION VI TROUBLESHOOTING

Problem

Probable Cause

Remedy

Lack of Proper

Lifting Speed.

1. Hoist overloaded.

1. Reduce load to within rated capacity of hoist.

2. Motor brake is dragging.

2. Check for proper brake adjustment or other defects. Sec paragraph 5-3.

3. Low voltage.

3. Bring up voltage to plus or minus 10% of voltage specified on hoist. Line

voltage should be measured while hoist is lifting load.

4. Overload limiting clutch intermittently slipping.

4. Replace clutch,

Load Brake

“Noise.” (Erratic

tapping sounds

or squeals)

1 . Need transmission oil change, or improper lubricant has

been used.

1. Change transmission oil. Sec Table 5-1.

Note: Hoist Warranty is void if unapproved oil is used.

2. Load brake malfunctioning.

2. Check load brake operation. See Figure 4-3.

Motor Brake

Noise or Chatter.

(While starting

hoist)

1. Brake needs adjustment.

1. Adjust as per paragraph 5-3.

2. Low voltage.

2. Check voltage at hoist power cord with hoist starting. Voltage should be no less

than 90% of the voltage specified.

Motor Brake

“Buzz.” (Anytime

hoist is running)

1. Brake needs adjustment.

1. Adjust as per paragraph 5-3.

2. Broken shading coil on brake frame.

2. Replace shading coil or complete brake frame assembly.

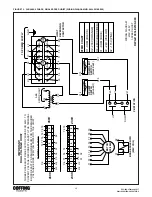

SECTION VII WIRING

SAFETY NOTES

Disconnect power from hoist before removing end covers.

7-1.VOLTAGE CONVERSION

Standard single speed units are convertible from 460 to 230 volts.

Conversion to the alternate voltage can be accomplished with the

following procedure.

a. Be sure power is disconnected from hoist. Remove long end

cover.

b. To convert the hoist from 460 to 230 volts, reconnect leads

T4, T5 , T6, T7, T8, T9, H2, H4, SI, and S2 per the 230 volt

connection diagram on Wiring Diagram, Figure 7-1.

Do not move any wires or make any changes to the wiring

except at the gray terminal block.

c. After converting voltage, check for proper phasing of three

phase units and check for proper limit switch operation.

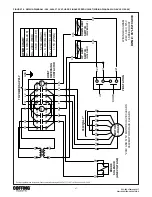

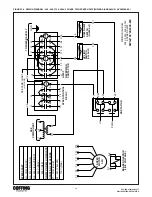

7-2. WIRING DIAGRAMS

The wiring diagrams for standard hoist models are reproduced on

the following pages. In addition, every hoist should have a wiring

diagram located inside the long end cover.