12

EC3-680-3 February 2017

Order # 5041558-0 & 5041679-0

INSPECTOR’S REPORT

ITEM

REMARKS (LlST DEFICIENCIES AND RECOMMENDED ACTION)

Inspector’s Signature

Date Inspected

Approved By

Date

FIGURE 4-2. RECOMMENDED INSPECTOR’S REPORT

4-3. PERIODIC INSPECTION

The exact period for the following inspections will depend on the

anticipated severity of hoist use. Determination of this period should be

based on the user's experience. It is recommended that the user begin

with a monthly inspection and extend the periods to quarterly, semi-

annually, or annually, based on his monthly inspection experience.

a. Clean hoist of any dirt or foreign material. Inspect bottom block

for accumulation of debris.

b. Perform all frequent inspections listed above.

c. Check for loose bolts, screws and nuts.

d. Check housings, load block. and other parts for wear,

corrosion, cracks or distortion. Check for abnormal openings

between housing sections.

e. Check motor brake for worn discs, oil contamination or

excessive clearance (see paragraph 5-3).

f. Check mechanical load brake function (see Figure 4-3).

g. Inspect the entire length of chain for gouges, nicks.

weld spatter, corrosion, distortion and wear. See CHAIN

INSPECTION, paragraph 4-5.

h. Inspect hooks and suspension pans for cracks, distortion or

extreme wear.

i. Inspect hooks for cracks using magnetic particle, dye penetrant

or other crack detecting methods.

j. Check limit switch set points and reset if necessary (see

paragraph 5-2).

k. Inspect all wiring for defective insulation and check to be sure

all electrical connections are tight. Check motor reversing

contactor or relay for burned contacts.

l. Inspect for oil leaks. Check oil level.

m. Inspect for missing or illegible capacity or warning labels.

n. Inspect the supporting structure for continued ability to support

the hoist rated load.

4-4. LOAD BRAKE FUNCTION CHECK

To check the functioning of the mechanical load brake, proceed as

follows:

a. Attach a light load to the hoist and lift it several inches.

b. DISCONNECT HOIST FROM POWER SUPPLY and re move

short end brake cover (see Figure 8-1, Index No. 1).

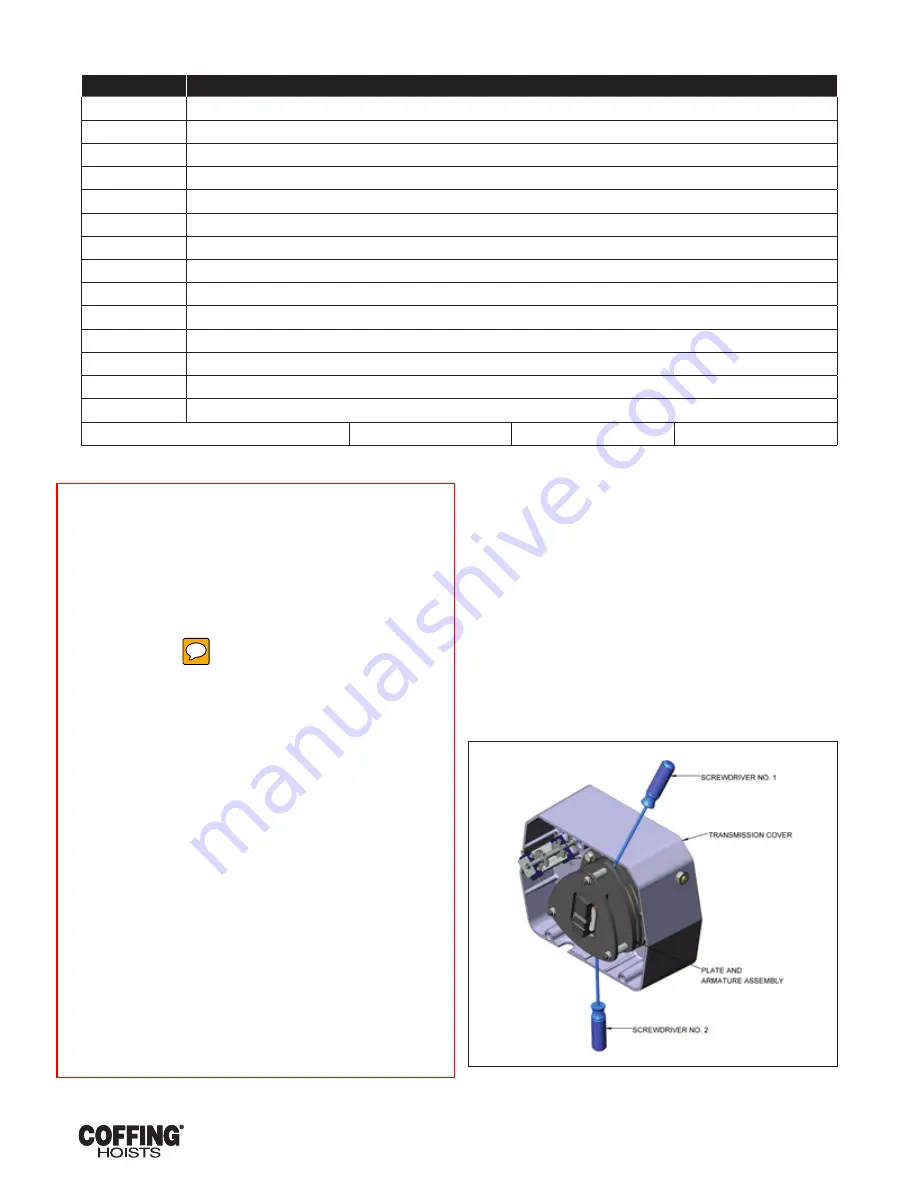

c. Referring to Figure 4-3 and Figure 8-8, place screwdrivers No. 1

and No. 2 behind the plate and armature assembly and prepare

to pry against the transmission cover.

NOTE: Do not allow either screwdriver to contact brake

disc (see Figure 8-8. Index No. 7).

d. Carefully pry open motor brake (close solenoid gap) and

observe action of load. If the load descends, the mechanical

load brake is malfunctioning and must be repaired.

FIGURE 4-3. LOAD BRAKE FUNCTION CHECK