14

EC3-680-3 February 2017

Order # 5041558-0 & 5041679-0

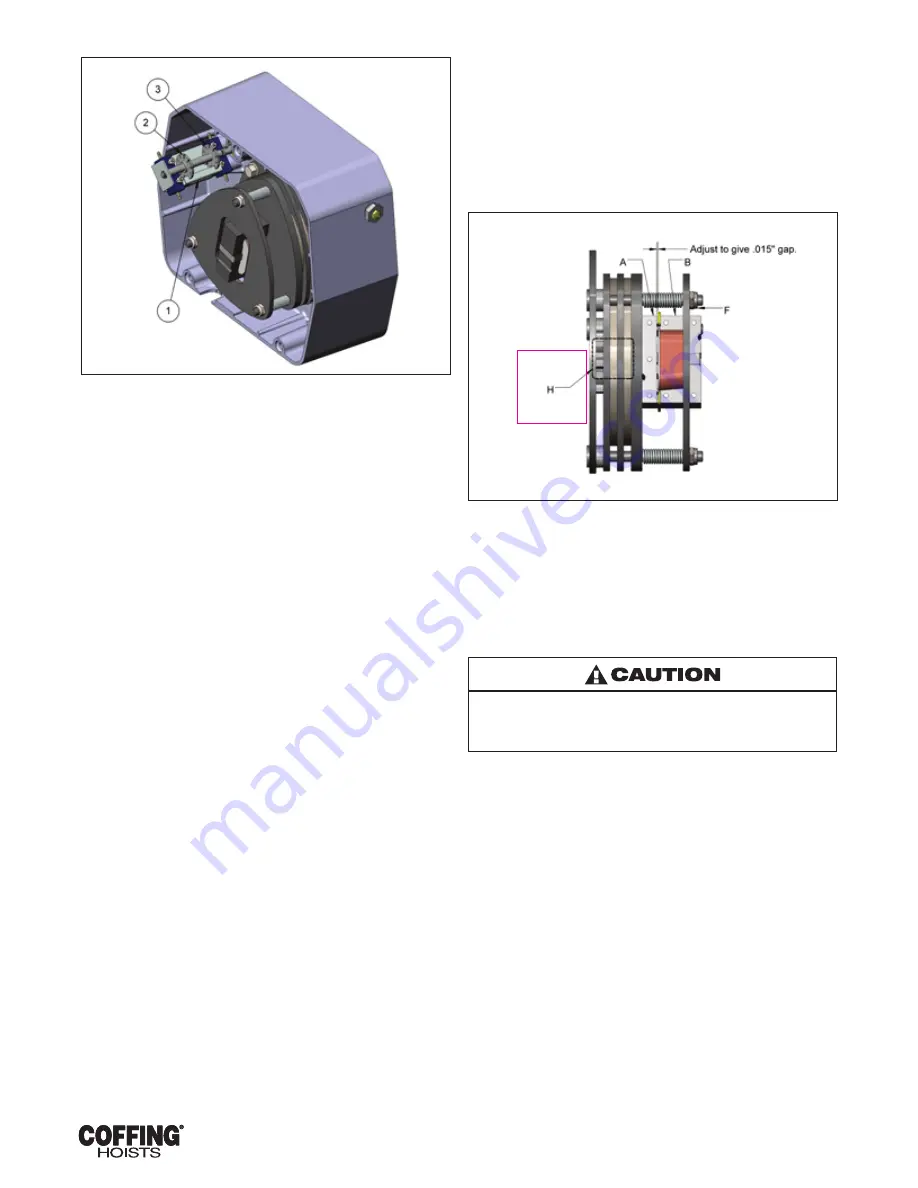

FIGURE 5-1. LIMIT SWITCH ADJUSTMENT

a. Adjusting Upper Limit (Brass Nut).

1. Carefully raise the load block to a point where its top is 3” or

more from the hoist housing.

2. DISCONNECT POWER from the hoist and remove the short

end cover.

3. With a screwdriver. pry the spring guide plate (No. 1 , Figure

5-1) out of the slots in the colored limit switch nuts (Nos. 2

and 3).

4. Tum the slotted brass nut (No. 2) toward its limit switch until

the switch clicks.

5. Release the spring guide plate and be sure it snaps back

into the slots in both nuts. Do not disturb the other slotted

nut if it has been previously set.

6. Replace the short end cover and reconnect power to the hoist.

7. Carefully raise the load block to its upper limit and observe

to see if it stops automatically at the desired point. Do

not allow the load block to run into the hoist housing. The

stopping point should be at least 3” below the hoist housing.

b. Adjusting Lower Limit (Zinc Nut)

1. Carefully lower the load block to a point where at least 12

links of Slack chain hang down from the hoist housing.

2. DISCONNECT POWER from the hoist and remove the short

end cover.

3. Adjust the zinc limit switch nut in the same manner

described above for the red nut.

4. Replace the short end cover and reconnect power to the

hoist.

5. Carefully lower the load block to its lower limit and observe

if it stops automatically at the desired level. Do not run chain

out of hoist or allow the slack end loop to become taut

against the hoist housing. At least 12 links of slack chain

should hang from the hoist.

NOTE: If upper and lower limits are not operating satisfactorily,

repeat adjustment.

5-3. MOTOR BRAKE ADJUSTMENT

When properly adjusted, the multiple disc motor brake should

release promptly, operate without noticeable chatter, and stop the

load with no more than one inch of drift. If the hoist hesitates to lift

the load promptly when the pushbutton is depressed. the brake

should be adjusted per the following procedure.

FIGURE 5-2. MOTOR BRAKE ADJUSTMENT

a. Remove any load and DISCONNECT POWER from hoist.

b. Remove the short end cover.

c. Referring to Figure 5-2, check the gap between armature (A)

and frame (B). The correct gap is .015”.

d. Adjust the gap by turning the three lock nuts (F) and check with

a feeler gauge to be sure the gap is the same on both ends of

the solenoid.

Be sure the bottom of the armature does not touch the

splined adapter (H). As wear occurs, the original clearance

will be reduced when this clearance is gone; THE BRAKE

DISCS MUST BE REPLACED.

e. Replace short end cover and reconnect power. If the brake

still chatters or is hesitant to release, refer to Section VI,

Troubleshooting.

5-4. TOP SUSPENSION REMOVAL

AND REPLACEMENT

A number of different top suspension assemblies are available to

accommodate different methods of hanging the hoist. If it should be

necessary to change top suspensions, proceed as follows:

a. DISCONNECT POWER from hoist and move the hoist to a safe

working area. If necessary, remove trolley to gain access to the

cap screws bolting the top suspension to the frame of the hoist.

b. Remove cap screws and lift off the suspension assembly.

NOTE: Due to the variety of mounting arrangements and

different reeving available on EC-3 Series hoists it is possible for

any suspension assembly to be mounted in several positions.

Refer to the diagrams of Figure 5-3 for proper suspension

location and orientation.

c. Check to be sure proper length cap screws are being used with

any change of top suspension. Screws should have ¾ to 1 inch

thread engagement.

d. Install new suspension assembly and tighten cap screws to

75 ft.-lbs. torque.