O

peration

15

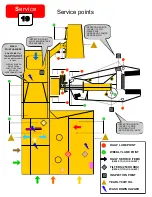

SHIM

REAR CLAMP ARM PIN ADJUSTMENT

Rear clamp arm pin requires periodic adjustment.

1.) Check for play in clamp arm by using pry bar, place bar

between lower case and clamp arm as indicated by green

arrow.

2.) If there is play remove cross bolt and adjust castle nut to

remove excessive play.

NOTE: MAINTAINING PROPER TORQUE ON REAR

CLAMP ARM PIN IS CRITICAL IN THE LONGEVITY &

RELIABILITY OF THE CLAMPING SYSTEM.

CROSS BOLT

CLAMP ARM WEAR PLATES

Clamp arm wear plates requires periodic adjustment.

1.) With use the clamp arm wear plates will get worn down.

2.) When worn enough to create a gap between the guide

arms use shims to take up the gap.

3.) To add shim pull clamp arm out, remove wear plate

bolts, install shim as needed & re-install bolts.

4.) Once wear plates are worn replace with new wear plate.

INSTALL SHIM FIRST ON LOWER WEAR PLATE, NEXT

SHIM UPPER WEAR PLATE WHEN GAP APPEARS.

WHEN GAP APPEARS WHEN BOTH WEAR PLATES

SHIMS INSTALLED REMOVE SHIMS & INSTALL NEW

WEAR PLATES.

NOTE: MAINTAINING PROPER TOLERANCE OF CLAMP

ARM WEAR PLATES IS CRITICAL IN THE LONGEVITY &

RELIABILITY OF THE CLAMPING SYSTEM.

Shaker operation tips

Summary of Contents for R Series

Page 1: ...OWNERS MANUAL COE S7 R SERIES SIDE MOUNT SHAKER VERSION 1 1 ...

Page 2: ......

Page 8: ...Operation 5 Cab OPERATORS CAB AREA DISPLAY JOYSTICK ...

Page 30: ...Service 27 Component locations 40A 40A 40A 40A AC 60A RADIATOR 100A 200A AC RADIATOR ...

Page 44: ...Circuits 41 S7R electrical circuit ...

Page 45: ...Circuits 42 ...