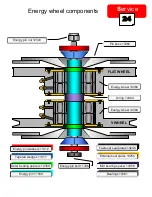

ENERGY WHEEL GREASE POINTS

Energy wheels require periodic grease service Each energy

wheel has 2 grease points (1 for each bearing)

1.) Grease energy wheels every other day of operation with

1-2 pumps.

2.) Only use recommended COE grease, the use of any

other grease will void warranty.

NOTE: USE OF NON COMPATIBLE GREASES WILL

CAUSE DETERIORATION OF GREASE LEADING TO

EVAPORATION OR SOLIDIFICATION OF GREASE. THIS

WILL CAUSE ENERGY WHEEL BEARINGS TO SEIZE.

ENERGY PIN BOLT NUT

Energy pin bolt nut requires inspection.

1.) New machines or when bolt is replaced require inspec-

tion every hour for the first day of use then daily thereafter.

2.) If bolt shows signs of loosening re-torque immediately.

NOTE: IF NUT IS NOT CHECKED REGULARLY AND

BACKS OFF A CATASTROPHIC FAILURE WILL OCCUR.

DAMAGE TO HEAD PIN BOSS & ENERGY WHEELS

WILL OCCUR.

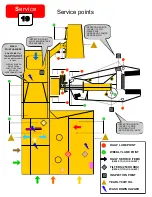

SHAKER HEAD BELT & ADJUSTMENT

Shaker head belt requires periodic adjustment.

1.) New shakers or new belt installations

require break in adjustment first 2 days of use.

Adjust 3 times a day during operation. Check

belt while hot on last day & adjust as needed.

2.) After initial break in adjust belt as needed.

3.) Properly adjusted belt should have no more

then

1/4”

downward travel.

4.) To adjust loosen 4 bolts & jam nut.

NOTE: FAILING TO ADJUST BELTS ON

SCHEDULE WILL RESULT IN FAILURE,

TWISTING OR THROWING OF BELT.

ADJUSTER

TIGHTEN LOOSEN

1/4”

ENERGY PIN BOLT NUT

O

peration

16

Shaker operation tips

Summary of Contents for R Series

Page 1: ...OWNERS MANUAL COE S7 R SERIES SIDE MOUNT SHAKER VERSION 1 1 ...

Page 2: ......

Page 8: ...Operation 5 Cab OPERATORS CAB AREA DISPLAY JOYSTICK ...

Page 30: ...Service 27 Component locations 40A 40A 40A 40A AC 60A RADIATOR 100A 200A AC RADIATOR ...

Page 44: ...Circuits 41 S7R electrical circuit ...

Page 45: ...Circuits 42 ...