21

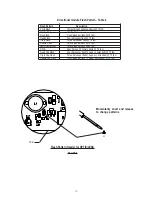

STROBE OPTION

TROUBLESHOOTING GUIDE

PROBLEM

Light heads do not

fire.

Only front

strobes flash.

CAUSE

a. Harness that connects power

supply to strobe head has loose

connections or damaged

h a r n e s s .

b . Faulty strobe Lighthead.

c . High voltage shorting to ground

(earth) through harness.

a . GREEN/BLACK control wire

connected to +12VDC overrides

o t h e r m o d e s .

SOLUTION

a. Check all connections.

Check harness by switching harness with functioning

strobe head.

Replace harness.

b . Check with known good lighthead.

c . Isolate shorted harness by disconnecting one at a time.

Replace harness.

a . See "Strobe Lighting Connections" section.

Reconnect switching.

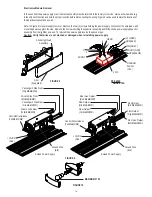

Troubleshooting

All CODE 360

®

lightbars are thoroughly tested prior to shipment. However, should you encounter a problem

during installation or during the life of the product, follow the guide below for information on repair and trouble-

shooting. Additional information may be obtained from the factory technical help line at 314-426-2700 ext. 2131.

NO STROBE LIGHTS IN THE LIGHTBAR OPERATE - Check the following: 1) +12 VDC source connection for the control switch box

and any in line fuse 2) Connection of the RED and RED/BLK or RED/WHT wire at the control switch box 3) Check the 15 Amp ATO fuse

on each power supply. If the fuse is blown, replace it with another 15 Amp fuse and test the lightbar. If the fuse continues to blow, return

the power supply only, NOT the entire lightbar, to the factory for service. For instructions on power supply removal see the " Electronics

Module Removal " section of this manual.

Do not replace the fuse with one of a higher rating. This will damage the power supply and void all

warranties.

WARNING!

!

ONE STROBE LIGHT MODULE DOES NOT OPERATE - Check the defective strobe light module by switching it with a module that is

known to be working.

No DIM a.Module White wire not connected a. Connect White wire to a switched source of +12V

to source of +12V