8

Dim Operation

Lightbar LED modules are equipped with a low power "Dimming" mode as standard. Dimming will be controlled by applying

+12V by way of the appropriate wire(color) in the wire harness/wire list. When DIM is engaged the LED's will operate in a

reduced power mode.

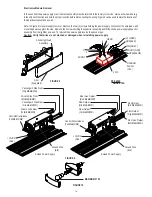

The DIM control wires( two white wires) located on each of the modules are connected from one module to the

next. To disable the dimming function on a particular module, disconnect the white wires. Then

reconnect the white wire to the white wire on another module that has dimming enabled.

The Dim setting reduces the light output of emergency warning lights reducing the effectiveness of them

especially in brightly lit areas. Failure to use adequate light for the circumstances can cause motorists to

fail to see the emergency vehicle and lead to serious personal injury or death. Never use the DIM

setting in a brightly lit area. Use of the DIM setting may cause emergency lights to not comply with

applicable emergency warning light standards. Use caution when using the DIM setting to assure that

motorists can clearly see the emergency vehicle.

!

WARNING!

For safety purposes, the corner modules in lightbars are not connected to the dimming circuit. This

ensures that when corner modules are turned on, full 360 degree coverage and compliance with

SAE warning light standards is provided.

Code 3® OPTIX™ 360 DEGREE CORNER MODULES

The Code360™ Lightbar may be equipped with Code 3® OPTIX™ 360 degree corner LED modules that provide a full 360

degree of warning.The optic has been designed to exceed all applicable requirements for 360 degree warning devices in Red,

Blue, and Amber. The new OPTIX corner module is a ( 1" X 6" ) module and uses larger, higher efficiency, TIR optics to produce

an enhanced corner signal over the exisitng ( 1" X 4" ) Code 3 LED X™ corner module. While the OPTIX will become the standard

corner module for most configurations, the LED X corner module will still be available and may be required for some configurations.

Installation and Operation for both modules will be the same. Consult the factory for further information.

Operating Specifications for 360 degree module:

Operating Voltage: 10-16 VDC, Reverse Polarity Protection

Current Draw :

Red/Amber - .5A avg @ 12.8 Volts

Blue/White - .8A avg @ 12.8 Volts

Available Colors - Red, Blue, Amber and White