15

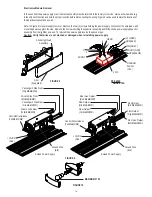

Multi-Functional Intersection Control System - This system allows multiple lighting options with a single pair of intersection lights. The

control center of the system is the Multi-Functional Control Module located in the lower section of the light bar. This combined with the

Sensing Lighthead Assemblies, located in the front lower section, allows the operator to select (4) four modes of operation - intersection,

driver side alley, passenger side alley and takedown positions.

Sensing Lighthead Assembly - As with the standard intersection lights, these are high intensity 120 degree oscillating light assem-

blies. With addition of the Position Sensing module these lights can be placed in the takedown or alley positions. (Figure 11)

Note: If the gear assembly is replaced, care must be taken to insure that the flat nylon washer is seated between the gear and the

bottom plate to prevent premature wear and failure.

Multi-Functional Control Module - Using

standard lighting controls the operator can select the

operation of the Lighthead assemblies.

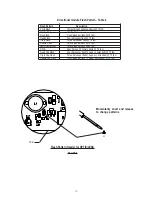

Figure 11

S50690 - Driver side assembly

S50691 - Passenger side assembly

S55401 - Multi-Functional Control Module

* - see wire tag for

exact wire color code.

Figure 12

WIRE

FUNCTION

GRN

ALLEY

BLK

GROUND

YEL

TAKEDOWN

RED

POWER