11

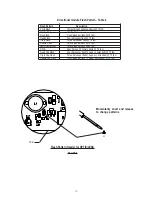

STROBE CONNECTIONS

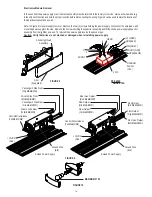

POWER CONNECTION

For all configurations the strobe power supply(s) will be powered by the #16AWG RED, and/or RED/BLK wires. For 2 or 4 head

configurations, one wire will be used, 6, 8, 10 and 12 head configurations will use two wires. These wires supply power to each

strobe power supply. All user switches and wiring connected to the RED,RED/BLK and or RED/WHT wires must be rated for a

minimum of 10 Amps and fused at a maximum of 15 Amps for each wire used.

Flash Patterns - All power supplies offer "Quad Flash" and "Random Flash". The flash patterns are controlled by jumpers on the

power supply and can be changed by first removing the power supply from the lightbar and then setting the jumpers. Refer to the

following tables:

Rear Only Flash Pattern

Connect the RED and/or RED/BLK wire in the 16 wire cable to +12 VDC through a user supplied

switch.

4/6 Head: Rear inboard and outboard strobes on each side will flash at a minimum rate of 70 FPM

(flashes per minute).

2 Head: If front or rear inboard strobes are present, strobes will flash at a minimum rate of 70 FPM.

Alternating Flash Pattern

Connect the RED and/or RED/BLK wire and GREEN wire in the 16 wire cable to +12 VDC through a

user supplied switch. This mode overrides REAR ONLY MODE.

4/6 Head: Front and Rear inboard and outboard strobes on each side will flash at a minimum rate of

70 FPM (flashes per minute).

2 Head: Front or rear inboard strobes will flash at a minimum rate of 70 FPM.

Pursuit Flash Pattern

Connect the RED and/or RED/BLK wire and GREEN/BLACK wire in the 16 wire cable to +12 VDC

through a user supplied switch. This mode overrides ALL OTHER MODES.

4/6 Head: Front inboard and outboard strobes on each side will flash at a minimum rate of 70 FPM.

2 Head: If front inboard strobes are present, strobes will flash minimum at a rate of 70 FPM.

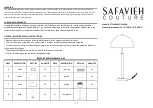

INTERSECTION LIGHTS - A high intensity 120° oscillator, located in the lower outboard corner of the light bar. Maintenance of

these units is much the same as for a typical rotator. Two mounting screws hold the assembly in place. Caution: Never install a

black worm on the 120° Intersection Light.

X-SWEEP - Dual halogen intersection lights, mounted one above the other on a common bracket, located in the lower outboard

corners of the lightbar.

X-FIRE - Upper-and lower-level strobes, mounted one above the other, 90 degrees to one another, located in the outboard

corners of the lightbar.

6-Head Flash Patterns (FIG.10)

Jumper

Quad

Random

Jumper

Quad

Random

J9

J36

J31

2 - 3

1 - 2

2 - 3

2 - 3

2 - 3

1 - 2

PSE 490E (FIG.10A)

YELLOW

Quad

Random

N/C

+12

4-Head Flash Patterns (FIG.10)