18

Motor

MOTOR (MODEL EJ4-4001 AND EJ8-4001A)

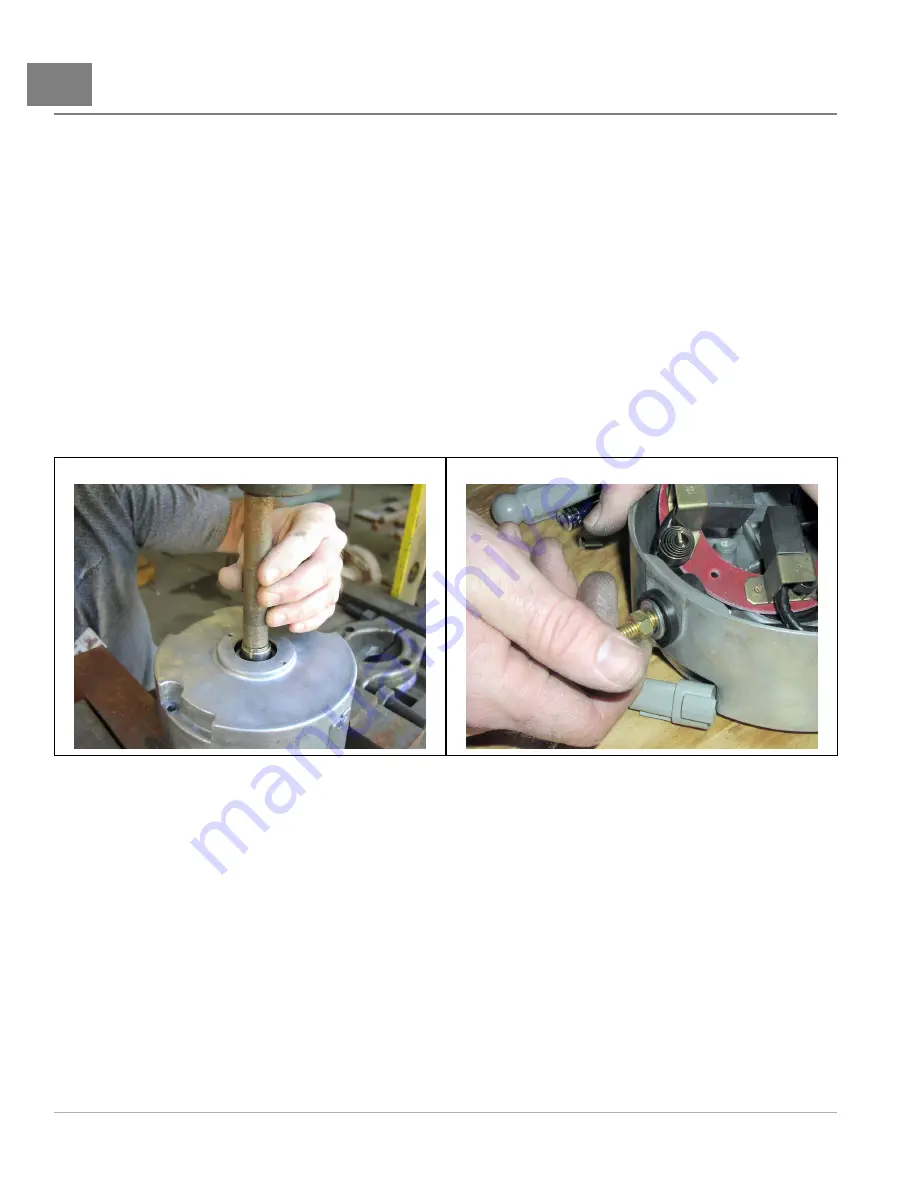

9.1. Place the end cap in a press with the armature facing down.

9.2. Place a bearing press tool with an outer diameter smaller than that of the armature shaft between the press

ram and the armature shaft

(Figure 18-8, Page 18-6)

.

9.3. Have an assistant support the armature while the press is activated.

10. Inspect the armature for wear and damage.

See Armature Inspection and Testing on page 18-7.

11. Inspect the motor frame and field windings.

See Motor Frame and Field Windings Inspection on page 18-9.

12. Remove the brush rigging.

12.1. Mark the brush terminal posts (A1 and A2).

12.2. Remove the two nuts securing the brush terminals (A1 and A2) to the end cap

(Figure 18-9, Page 18-6)

.

12.3. Remove the two screws and the brush rigging to the end cap

(Figure 18-10, Page 18-7)

.

13. Inspect the terminal insulators.

See Terminal Insulator Inspection on page 18-9.

14. Remove the bearing from the end cap.

14.1. Remove the retaining ring that secures the bearing in the end cap

(Figure 18-11, Page 18-7)

.

14.2. Use an arbor press to remove the bearing from the end cap.

15. Inspect the bearing for wear and damage.

See Bearing Inspection on page 18-10.

752

Figure 18-8

Armature Removal

753

Figure 18-9

A1 and A2 Terminals

Page 18-6

2009 Electric Precedent Maintenance and Service Manual