Casing Assembly

Model FLE Assembly

3-14

750-192

Figure 3-24. Finishing the Wetpack Insulation

Installation

Figure 3-25. Packing the Top of the Walls

Figure 3-26. Filling the Joint with Silicone Caulking

5. Finishing the Wetpack Installation

Around the Lower Drum

•

Unfold the wetpack to cover the lower drum and

tubes. Cover the entire base drum, overlapping

adjoining wetpack rolls. Continue to mold the wet-

pack around the lower drum and tube sections to

prevent the plates from coming apart while packing

the insulation (Figure 3-24).

•

The wetpack should be positioned to be level with, or

just outside the base refractory at the front.

6. Finish Installing Backing Plates

•

As in step 3, install the front upper and lower back-

ing plates.

7. Install Front Wall Section

To install the front wall section, repeat the same

steps used to install the rear wall. In a hot water

unit, the front wall will be one piece and the instal-

lation will be much easier, but the front wall of a

steam boiler will have two pieces just like the rear.

8. Install Roof Panel

•

Tidy the top of the walls to get them ready for the

roof (pack the insulation, wipe off the wall, etc) (Fig-

ure 3-25).

•

Fill any joints in the top of the front and rear walls

with silicone caulking (Figure 3-26).

•

Using spray adhesive, place a strip of 1/4” paper

gasket along the width of the front and rear walls

(Figure 3-27). Using the same process, place a small

square of the material on the 4 inside corners of the

walls, allowing a little metal to show through (Figure

3-28).

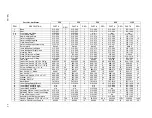

Summary of Contents for FLE

Page 1: ...Model FLE Assembly Instructions 750 192 07 09 Field Erectable Flexible Watertube Boiler ...

Page 4: ...iv Notes ...

Page 8: ...viii ...

Page 16: ...General Description Model FLE Assembly 1 8 750 192 ...

Page 34: ...3 2 750 192 Figure 3 1 Typical Hot Water Flextube Casing ...

Page 36: ...3 4 750 192 Figure 3 2 Typical Low Pressure Steam Flextube Casing ...

Page 38: ...3 6 750 192 Figure 3 3 Typical High Pressure Steam Flextube Casing ...

Page 56: ...Casing Assembly Model FLE Assembly 3 24 750 192 ...

Page 58: ...750 192 4 2 Figure 4 2 Fuel Train Components ...

Page 60: ...4 4 750 192 Figure 4 5 Typical conduit layout ProFire burner on a hot water Flextube boiler ...

Page 61: ...750 192 4 5 Figure 4 6 Typical conduit layout ProFire burner on a steam Flextube boiler ...

Page 62: ...4 6 750 192 Figure 4 7 Nameplate locations hot water boiler ...

Page 63: ...750 192 4 7 Figure 4 8 Nameplate locations steam boiler ...

Page 64: ...e mail info cleaverbrooks com Web Address http www cleaverbrooks com ...