Pressure Vessel Assembly

Model FLE Assembly

2-16

750-192

10. Installation of Pressure Vessel to

Base

If the pressure vessel has been built on stands or is

suspended, follow the earlier procedures for

mounting and securing the pressure vessel to the

base.

Figure 2- 29: Leak testing the completed pressure

vessel to the boiler design pressure

WARNING -

The assembled Model FLE

pressure vessel is heavy. Until the pressure

vessel is secured to the base, it will be

unstable when standing in an upright position.

Failure to adequately and properly restrain

and/or suspend the drum and tube assembly

prior to securing it to the base may allow the

assembly to fall with the possibility of causing

serious personal injury or death

11. Pressurized Leak Test

After the pressure vessel has been assembled, a

leak test must be performed. The leak test takes as

much time as is needed to check that there are no

leaks. The assembler is responsible for arranging

and preparing for the leak test. An air compressor

capable of pressurizing the flooded pressure vessel

to its design pressure will be required.

If any ferrule-to-drum joint leaks are apparent, the

affected ferrule will need to be driven deeper into

the drum. Relieve the hydraulic pressure, remove

the retainer plate and drive the ferrule deeper into

the drum. Drive the ferrule only far enough to

eliminate leakage.

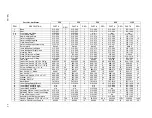

Table 2- 2: Recommended Pressure for Leak Test

A leak test requires that the following must be

attended to:

• Connection points to the pressure vessel must be

blocked with blind flanges, plugs, or caps

capable of withstanding the required test

pressure.

• A valve capable of withstanding the required test

pressure must be installed in the vent fitting at the

top of the pressure vessel.

• A source of clean water with a minimum

temperature of 70°F must be available to fill the

pressure vessel.

CAUTION -

Before resealing the

ferrules, relieve pressure from the vessel.

Once the ferrules are resealed, repeat the

pressurized leak test.

Figure 2-29. With the vessel flooded and

pressurized, check for leaks at all ferrules and

flanges

Boiler Design

Recommended

Pressure for Leak Test

15 psi Steam

15 psi

150 psi Steam

150 psi

160 psi Hot Water

160 psi

Summary of Contents for FLE

Page 1: ...Model FLE Assembly Instructions 750 192 07 09 Field Erectable Flexible Watertube Boiler ...

Page 4: ...iv Notes ...

Page 8: ...viii ...

Page 16: ...General Description Model FLE Assembly 1 8 750 192 ...

Page 34: ...3 2 750 192 Figure 3 1 Typical Hot Water Flextube Casing ...

Page 36: ...3 4 750 192 Figure 3 2 Typical Low Pressure Steam Flextube Casing ...

Page 38: ...3 6 750 192 Figure 3 3 Typical High Pressure Steam Flextube Casing ...

Page 56: ...Casing Assembly Model FLE Assembly 3 24 750 192 ...

Page 58: ...750 192 4 2 Figure 4 2 Fuel Train Components ...

Page 60: ...4 4 750 192 Figure 4 5 Typical conduit layout ProFire burner on a hot water Flextube boiler ...

Page 61: ...750 192 4 5 Figure 4 6 Typical conduit layout ProFire burner on a steam Flextube boiler ...

Page 62: ...4 6 750 192 Figure 4 7 Nameplate locations hot water boiler ...

Page 63: ...750 192 4 7 Figure 4 8 Nameplate locations steam boiler ...

Page 64: ...e mail info cleaverbrooks com Web Address http www cleaverbrooks com ...