Disturbances, possible causes and measures

DWP - 1106 A | Version 1.03

13

12.4Disposal via municipal collection

points

Disposal of used electrical and electronic equipment

(Applicable in the countries of the European Union and

other European countries with a separate collection sy-

stem for this equipment).The symbol on the product or its

packaging indicates that this product should not be trea-

ted as normal household waste, but should be handed in

at a collection point for the recycling of electrical and

electronic equipment. By helping to dispose of this pro-

duct correctly, you will help protect the environment and

the health of those around you. The environment and

health are endangered by incorrect disposal. Material

recycling helps to reduce the consumption of raw materi-

als. For more information about recycling this product,

contact your local authority, municipal waste disposal

service or the shop where you purchased the product.

13 Disturbances, possible cau-

ses and measures

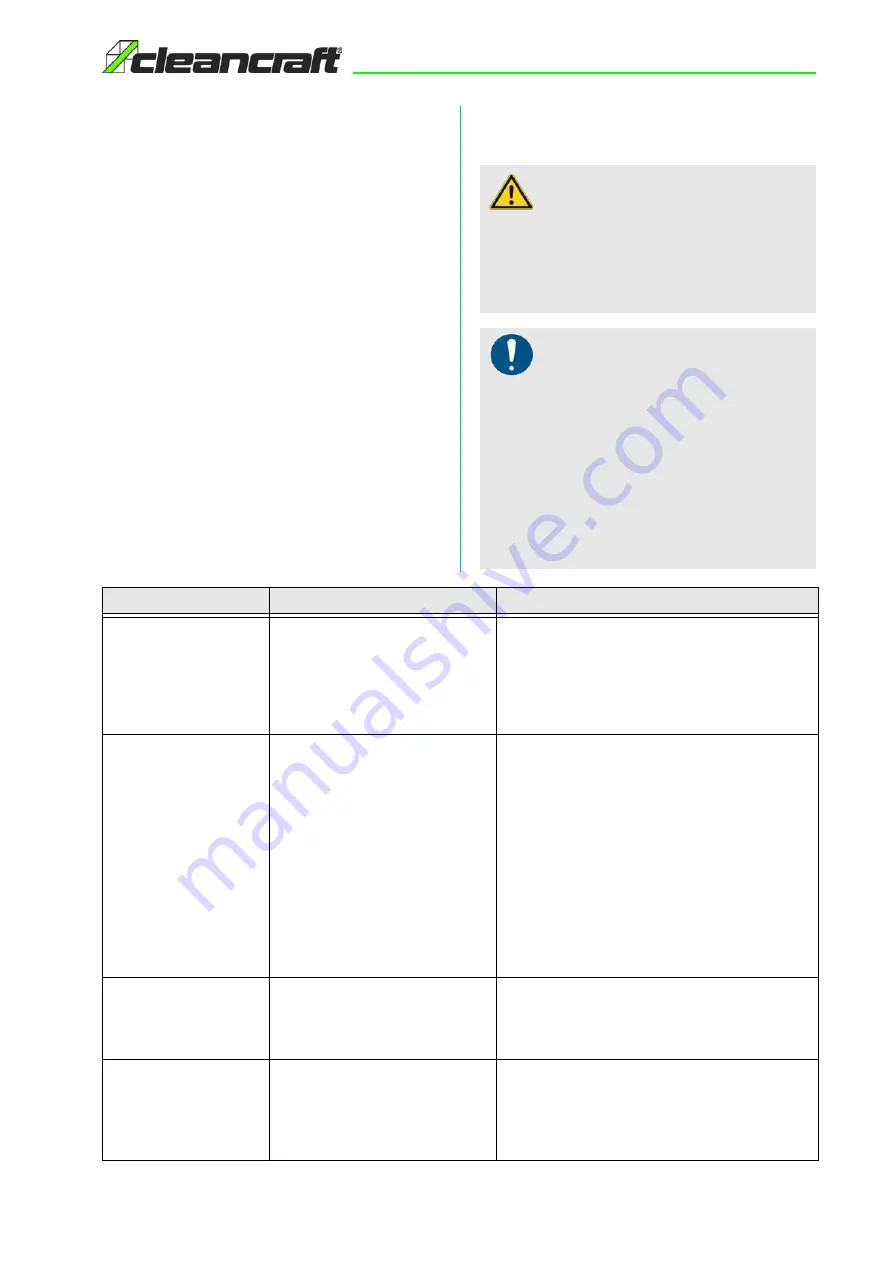

ATTENTION!

If one of the following errors occurs, immediately stop

working with the water pump. Before you begin

troubleshooting, turn off the water pump and unplug

the power cord. Otherwise it could lead to serious inju-

ries. All repairs or replacement work may only be car-

ried out by qualified and trained specialist personnel.

NOTE!

If you can not solve the problems with your water

pump yourself, then please contact your nearest

CLEANCRAFT dealer. Please write down the follow-

ing information from the water pump or the operating

instructions in advance to help you with your problem

in the best possible way.

-Model name of the device

-Serial number of the device

-Construction year

-Exact error description

Fault

Possible cause

Remedy

Engine will not start

1. No electricity available

2. Capacitor defective

3. Motor shaft or bearing blocked

4. Motor protection tripped

1. Check with a GS-compliant device that voltage is

present. Check mains plug.

2. Contact customer service

3. Check the cause and free the pump from the

blockage.

4. Check pump and allow to cool

The engine is running

but the pump does not

deliver any liquid.

1. The pump is not completely sub-

merged

2. Ingress of air into the

suction line.

3. Blockage of the intake

4. Outdoor temperature too low

(Frozen water)

5. Defective water pipes

1. Check the pump

2. Check and make sure that

the suction line and all connections are tight.

the inlet of the suction line including the check

valve is immersed in the delivery liquid.

the check valve with suction filter closes tightly and

is not blocked.

there are no siphons, kinks, opposite slopes or re-

strictions along the suction lines.

3. Remove dirt in the intake area.

4. Increase the temperature, start the pump as

soon as the ice has completely thawed.

5. Check water pipes, replace if necessary

Suction decreases.

Blockages in the suction nozzle, in-

take manifold, suction hose or filter.

1. Remove blockages.

2. Clean or change the filter.

3. Insert the filter cover correctly.

4. Check correct installation position of the filter.

Pump works for a short

time, but then shuts off

1. Unstable or too high or low

mains supply

2. Liquid too thick

3. Blockage of the intake

4. Pump / motor overheated

1. Check the supply voltage according to the rating plate

2. Check fluids

3. Check the intake filter

4. Check pump / motor and allow to cool