9

MAINTENANCE

WARNING! MAKE SURE THAT THE AIR NAIL GUN IS DISCONNECTED FROM THE AIR SUPPLY

BEFORE STARTING ANY CLEANING, OR MAINTENANCE PROCEDURES.

LUBRICATION

•

Only use the oil provided to lubricate the air nail gun.

•

Lubricate the moving parts of the safety yoke and trigger mechanism before

using the nailer.

•

Do not use detergent oils or any oil that contains artificial additives as these may

cause the nailer to malfunction.

•

Place 2 or 3 drops of lubricating oil into the air intake hose connection point twice

a day when the nailer is being used. A bottle of CLARKE Air Line Oil** is supplied

with the kit.

CLEANING

•

Keep the body of the nailer clean and free from debris.

•

Make sure that the magazine release lever and the trigger are kept clean and in

good working order.

•

Clean the magazine and nail pusher by blowing with compressed air.

SERVICE AND REPAIR

•

All servicing and repair must be carried out by qualified service technicians.

NOTES

Be aware that factors other than the tool may effect its operation and efficiency such as

reduced compressor output, excessive drain on the airline, moisture or restrictions in the

line, or the use of connectors of improper size or poor condition which will reduce air

supply.

**Clarke Air Line Oil is available from your CLARKE dealer part no. 3050825.

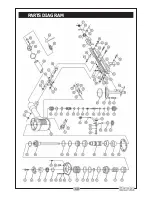

Summary of Contents for Contractor CFN34

Page 10: ...10 PARTS DIAGRAM...