11

PARTS LIST

No. Description

Part No.

No. Description

Part No.

9

PARTS & SERVICE TEL: 020 8988 7400

or e-mail as follows:

PARTS: [email protected]

SERVICE: [email protected]

1

Bolt M8X30

HTCFN34001

2

Air deflector

HTCFN34002

3

Deflector rubber

HTCFN34003

4

Spring

HTCFN34004

5

Spring wire

HTCFN34005

6

Bolt M6X30

HTCFN34006

7

Spring washer

HTCFN34007

8

Flat washer

HTCFN34008

9

Cylinder core

HTCFN34009

10

Bolt M5X5

HTCFN34010

11

Cylinder cover

HTCFN34011

12

O-ring 41.7x3

HTCFN34012

13

O-ring 56x3.1

HTCFN34013

14

Head valve Piston

HTCFN34014

15

Spring seat

HTCFN34015

16

Compressed spring

HTCFN34016

17

Spring washer

HTCFN34017

18

Collar

HTCFN34018

19

O-ring 42.3x5

HTCFN34019

20

Main Piston

HTCFN34020

21

O-ring 57.5x3

HTCFN34021

22

O-ring 88x3

HTCFN34022

23

Fixed ring

HTCFN34023

24

Sealing ring

HTCFN34024

25

Cylinder

HTCFN34025

26

Bumper

HTCFN34026

27

Cylinder washer

HTCFN34027

28

Gun body

HTCFN34028

29

Rubber washer

HTCFN34029

30

Trigger valve seat

HTCFN34030

31

O-ring 15x2.65

HTCFN34031

32

O-ring 17x1.5

HTCFN34032

33

Trigger valve guide

HTCFN34033

34

O-ring 6.1x1.8

HTCFN34034

35

O-ring 6.4x2

HTCFN34035

36

O-ring 9x1.8

HTCFN34036

37

Switch spring

HTCFN34037

38

Switch pipe

HTCFN34038

39

O-ring 2.5x1.5

HTCFN34039

40

O-ring 20.3x2.3

HTCFN34040

41

Switch seat

HTCFN34041

42

Trigger Pin

HTCFN34042

43

Trigger

HTCFN34043

44

O-ring 1.7x2

HTCFN34044

45

Safety spacer

HTCFN34045

46

Pin 3x16

HTCFN34046

47

Safety guide

HTCFN34047

48

Pin 3x25

HTCFN34048

49

Compressed spring

HTCFN34049

50

Bolt M5x8

HTCFN34050

51

Flat washer

HTCFN34051

52

Spring washer

HTCFN34052

53

Adjust nut

HTCFN34053

54

Safety yoke

HTCFN34054

55

Safety Nose

HTCFN34055

56

Copper collar

HTCFN34056

57

Safety nose case

HTCFN34057

58

O-ring 59x1.8

HTCFN34058

59

Driver guide

HTCFN34059

60

Spring washer

HTCFN34060

61

Bolt M8X25

HTCFN34061

62

Bolt M6X12

HTCFN34062

63

Magazine

HTCFN34063

64

Drive nail bar

HTCFN34064

65

Bolt M4x8

HTCFN34065

66

Nut M4

HTCFN34066

67

Flat washer

HTCFN34067

68

Bolt M4x40

HTCFN34068

69

Safety pipe

HTCFN34069

70

Safety pipe case

HTCFN34070

71

Pin case

HTCFN34071

72

Spring Pin

HTCFN34072

73

Bolt M6X12

HTCFN34073

74

Pusher

HTCFN34074

75

Spring pin 3X20

HTCFN34075

76

Spring pin 5X20

HTCFN34076

77

Bolt M3X14

HTCFN34077

78

Nut M3

HTCFN34078

79

Pin B4X30

HTCFN34079

80

Spring

HTCFN34080

81

Spring core

HTCFN34081

82

Pin B5X12

HTCFN34082

83

Release latch

HTCFN34083

84

Block

HTCFN34084

85

Spring

HTCFN34085

86

Bolt M5X25

HTCFN34086

87

Fixed seat

HTCFN34087

88

Nut M6

HTCFN34088

89

Nut M5

HTCFN34089

90

Rubber handle case

HTCFN34090

91

End cap washer

HTCFN34091

92

End cap

HTCFN34092

93

Flat washer

HTCFN34093

94

Bolt M5x20

HTCFN34094

95

Air plug

HTCFN34095

96

Air plug case

HTCFN34096

Summary of Contents for Contractor CFN34

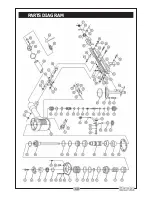

Page 10: ...10 PARTS DIAGRAM...