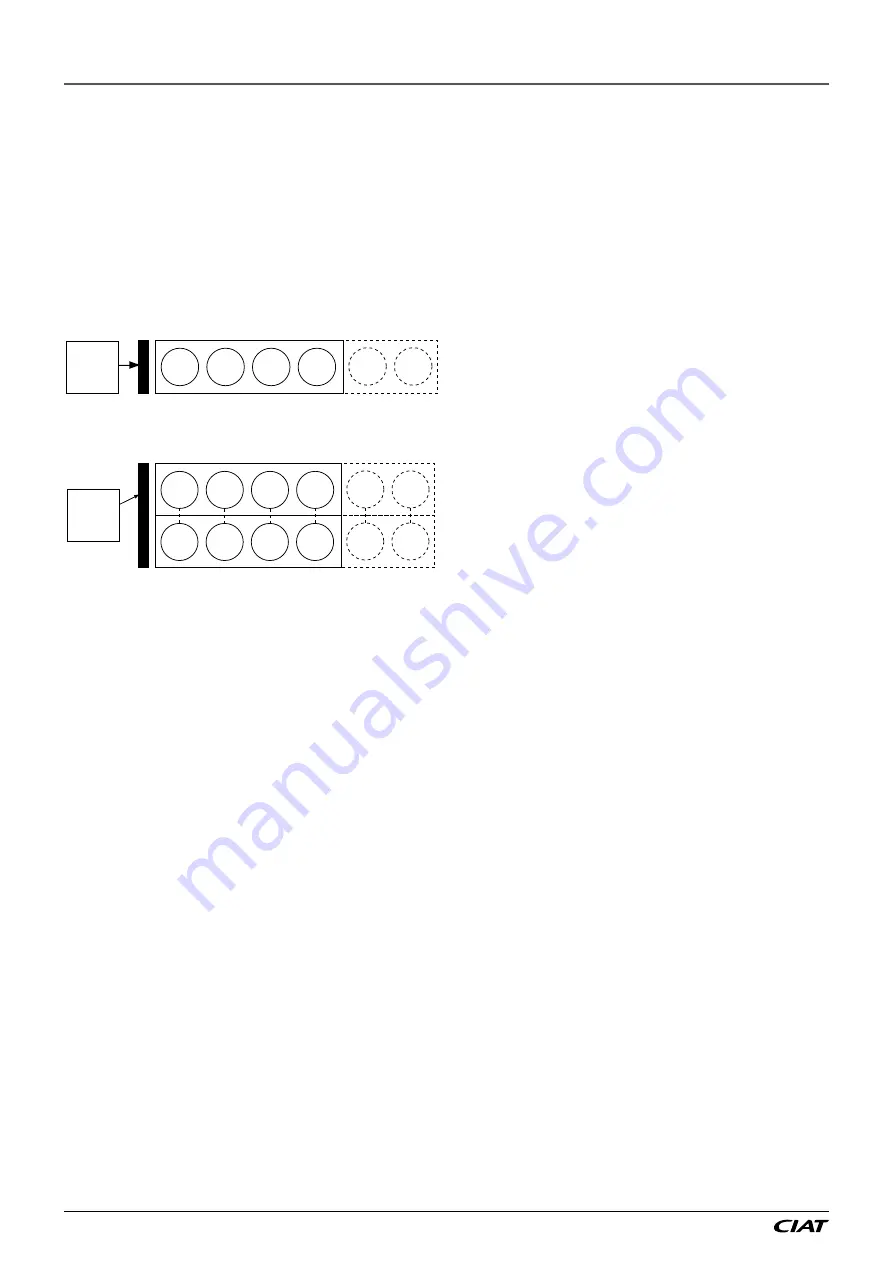

14.2.5.4 - Fan stage assignment

To ensure correct operation, a minimum of two stages is required.

Depending on the drycooler capacity the number of fans can be

between 2 and 8. They can be controlled by one fan or by linked

pairs, if necessary.

For example, a drycooler with 4 or 6 fans installed in series along

the length of the unit will result in a configuration of 4 or 6 fan

stages.

On the other hand, a drycooler with 8 or 12 fans arranged in

pairs along the length of the unit will also result in a configuration

of 4 or 6 fan stages.

Configuration with 4 and 6 stages (min. 2 - max. 8)

1

2

3

4

5

6

A

Fans linked in pairs -

4 and 6-stage configuration (min. 2 - max. 8)

1

2

3

4

5

6

A

1

2

3

4

5

6

Legend

A

Water inlet and outlet pipe side

1 to 6

Fans

14.2.5.5 -

Units without evaporator and condenser pump,

3-way valve configuration for low outside temperature

application

Units can be provided from the factory without evaporator and

condenser pump. If year-round low-temperature operation is

planned, the unit will be installed with a 3-way valve that is not

provided with the unit.

In this case Connect’Touch should be configured for 3-way valve

system control from an analogue 0-10 volt output on the master

board. An adequate condensing temperature will be maintained

with constant condenser flow rate. This configuration permits

year-round system operation down to -20°C outside temperatures.

Controlling and changing-over the fan stages, described in

chapter “Configuration of the number of fan stages and automatic

changeover of the fan stages” is identical.

14.2.5.6 -

Drycooler installation on units

When installing the drycooler, follow professional guidelines.

-

Water pipe sizing

-

Maximum piping and shut-off valve pressure drops based on

the available pressure of the unit pumps

-

Maximum drycooler elevation in relation to the unit (safety

valve at 4 bar on the unit water circuit).

-

Fan stage control (see “Fan stage control”).

-

Correct positioning of the outside air temperature and

drycooler outlet water temperature sensors.

14.2.6 -

LGN unit operation with a remote air-

cooled condenser

14.2.6.1 - Operating principle

LGN units have been specially designed to optimise the operation

of split installations, using air-cooled condensers as the chiller

heat rejection system. The installation of an operational system

is limited to the connection of the air-cooled condenser inlet and

outlet piping to the LGN unit.

The Connect Touch control system of the LGN includes a logic

to permit control the different fixed and variable-speed fan

variants.

14.2.6.2 -

Lead fan

The physical position of the air-cooled condenser with fixed or

variable-speed fans depends on the position of the leaving liquid

refrigerant manifold. In all cases there is always a so-called lead

fan. This is the fixed or variable-speed fan that is physically the

closest to the leaving liquid refrigerant manifold.

This ensures optimum subcooling on the condenser outlet side,

especially at part load. This is the first fan to start in each circuit

and the last fan to stop. A fan configuration with fixed-speed fans

permits year-round system operation down to 0°C outside

temperature.

A fan configuration with a variable-speed lead fan permits year-

round operation down to -10°C outside temperature.

14.2.6.3 - Communication to control the remote

condenser

The electronic board specifically integrated in the control box of

the remote condenser(by an option selection on the manufacturer

condenser) and a LEN communication BUS connected to the

microprocessor board of the unit are used for the overall system

control.

The option is supplied in the manufacturer condenser control

box. Connect the unit to board AUX1 in the condenser, using a

communication cable. The communication cable should be

connected to the plug with 3 points Wago type (5 mm spacing

or equivalent). The communication cable should be a shielded

type.

The option includes an air temperature sensor installed on the

condenser.

Connect Touch continuously optimises system operation to obtain

the best system efficiency by controlling the number of fans

required for any thermal load and outside temperature conditions.

14.2.6.4 -

Configuration of the number of fan stages and

fan type based on the air-cooled condenser model used in

the installation

Please refer to the instructions in the Connect Touch IOM units

to carry out the parameter setting of the air-cooled condenser

used in the installation:

-

Use of speed variation on the lead fan(s)

-

Number of fixed-speed fans

Based on the parameter setting used, the arrangement of the

digital and corresponding analogue outputs controlling the

fans will be activated by the control.

Connect Touch controls the automatic switching of all fan stages,

based on operating time and number of start-ups of the different

stages. This function prevents fan motors from only running a

little or not at all and the shafts seizing up, especially during

periods with a low cooling demand, when the outside temperature

is low. Switching is often specified by the condenser manufacturers

to ensure a long operating life of the fan motors that are only

used a little or not at all in these particular operating conditions.

14 - OPTIONS ET ACCESSORIES

Dynaciat LG/LGN

EN-58

Summary of Contents for DYNACIAT LG 080

Page 1: ...DYNACIAT LG LGN 07 2018 10188 Instruction manual...

Page 2: ...Dynaciat LG LGN EN 2...

Page 3: ...EN 3 Dynaciat LG LGN...

Page 67: ...EN 67 Dynaciat LG LGN...