H

List of faults

d1.0

compressor discharge - level 0

d1.1

compressor discharge - level 1

d1.2

compressor discharge - level 2

d2.0

water circulation - level 0

d2.2

water circulation - level 2

d3.2

Antifrost limit - level 2

d4.0

Brazed plates exchanger antifrost - level 0

d4.1

Brazed plates exchanger antifrost - level 1

d4.2

Brazed plates exchanger antifrost - level 2

d5.0

Low pressure - level 0

d5.1

Low pressure - level 1

d5.2

Low pressure - level 2

d6.0

High pressure - level 0

d6.1

High presure - level 1

d6.2

High pressure - level 2

d7.0

Defrosting - level 0

d7.1

Defrosting - level 1, goes to d7.2 when switching from

heating mode to cooling mode or stop

d7.2

Defrosting - level 2

d8.2

Immersed electrode safety device - level 2 or manual

thermostat safety device 63

°

C in PCR

d9.1.1. Coil refrigerant sensor - level 1

d9.1.2. Coil refrigerant sensor - level 2

d9.2.1. Plate heat exchanger refrigerant sensor - level 1

d9.2.2. Plate heat exchanger refrigerant sensor - level 2

d9.4.1. External sensor - level 1

d9.4.2. External sensor - level 2

d.9.5.1. Compressor discharge sensor - level 1

d9.5.2. Compressor discharge sensor - level 2

d9.6.2. Sensor on water/refrigerant fluid exchanger water

return - level 2

d.9.7.2. Sensor on water/refrigerant fluid exchanger water

departure - level 2

d.9.8.

Ambient thermostat sensor fault

d.9.9.

Ambient thermostat potentiometer fault

d.10.2. Eeprom memory - level 2

d.11.0

Climbox 2 programmer liaison - level 0

d.12.0

Liaison MCAD5 - level 0

H

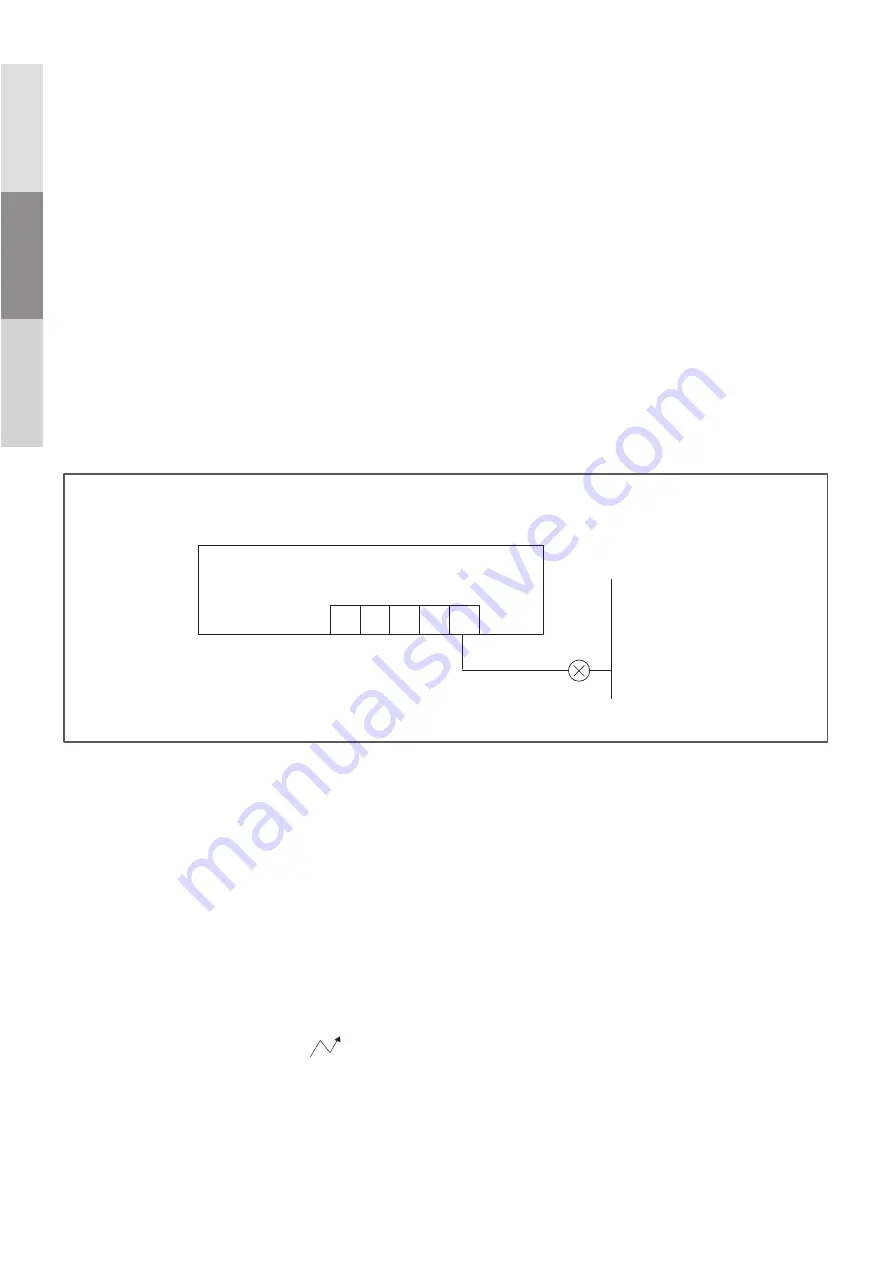

Fault transfer

The MRS5.1 card offers a neutral type fault transfer on terminal

5 of terminal box J5 ; in case of level 1 or 2 fault, this terminal

acts as a neutral.

Utilization example : visualization of faults by lamp lighting.

Maximal load on terminal 5 : 10A resistive

5

J5

MRS 5.1

Ph (230 V)

"

Verifications before commissioning

– Make sure of the absence of refrigerant fluid leak

– Make sure that water circulates in the generator when the

circulator is operating

– Purge the air of the hydraulic circuit

– Check the tightening of all the electrical connections

– Make sure that the network voltage corresponds to the unit

voltage and that its value remains within the admissible limits

(+6% –10% in relation to the nominal voltages)

"

Starting sequence

Before putting under voltage, check that the hydraulic circuit is

supplied with water.

Put the unit under voltage (the green LED

of the MRS5.1

lights up and the display panel gives the water return tempera-

ture). The thermodynamic unit is stopped. Check that the circu-

lator operates.

Press the MRS5.1

CONFIGURATION

key for modifying and

validating the parameters which will serve your installation.

Press keys

+ / –

for reaching the parameter to be modified, on

Pr

value display, on

+ / –

for modification of values and finally on

Pr

for parameter validation.

For parameters P01 to P18 modification, you must first transfer

P15 on 0 by positioning yourself on P15 and pressing simulta-

neously keys

–

and

reset

.

"

List of basic parameters to be set

before starting

P04 control

mode

Value 0 : Climbox 2 programmer

Value 1 : All or nothing entries

Value 2 : remote control MCAD5

P12

Hydraulic pump operation type

Value 0 : continuous operation

Value 1 : economical operation in anti-freeze

and absence period

P07

Choice of hydraulic network

Value 0 : fan coil unit

Value 1 : cooling heating floor (PCR)

If P07 = 1, you must also adjust :

P09 ambient temperature above which the unit will

ensure the cooling

(factory setting : 25

°

C)

P18 ambient temperature desired in the room in

heating (factory setting : 20

°

C)

P02

Cooling regulation as a function of the outside

temperature (accessible only if P07 = 0)

Value 0 : no

Value 1 : Yes

P03

Heating regulation as a function of the outside

temperature

Value 0 : no

Value 1 : yes

P35

Water return setting in heating mode

P36

Water return setting in cooling mode

français

Deutsche

English