Chiltrix Inc.

System filling with Propylene Glycol and water

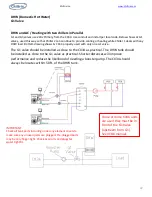

At or near the CX34 a flush/fill valve assembly must be installed. This can be made with three ball valves

and a couple hose fittings. See example below.

Pre-mix the propylene glycol in a container large enough to hold the loop volume plus a few gallons.

Using a filling pump and 3 hoses, place one hose in the glycol container and connect it to the suction

side of the pump. Connect the second hose to the pump discharge and the other end to valve “C”

that is closest to the fan coils. Using a third hose, connect it to valve ”B”, closest to the chiller and

leave the open end in the glycol bucket. Close the middle ball valve “A”. Close the middle ball valve

“A”. The pump should be pumping away from the CX34 chiller. Open and close valve “A” a few times

to remove trapped air. The pump should be pumping away from the CX34 chiller.

Run the pump until there are no more air bubbles coming out of the loop. After all air is expelled

from the loop, close valve “B” and then open valve “A” with the pump running. When the pressure

gage on the CX34 shows at least 30 psi close valve “C” and turn off the pump. Minimum loop

pressure is 14.5 psi, maximum pressure is 43.5 psi, and ideal pressure is 20-30 psi.

29

Summary of Contents for CX34-4

Page 4: ...Chiltrix Inc www chiltrix com CX34 Components 4 ...

Page 18: ...Chiltrix Inc www chiltrix com Electric Connections and Component Locator 18 ...

Page 19: ...Chiltrix Inc www chiltrix com CX34 System Wiring Diagram 19 ...

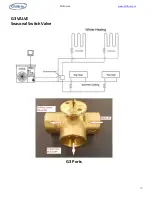

Page 25: ...Chiltrix Inc www chiltrix com G3 VALVE Seasonal Switch Valve G3 Ports 25 ...

Page 34: ...Chiltrix Inc www chiltrix com 34 Language Screen Screen Saver ...

Page 35: ...Chiltrix Inc www chiltrix com 35 Touch Screen Fixing Calibration Time Setting ...

Page 52: ...Chiltrix Inc www chiltrix com 52 ...