CM6SV65 and 83

Installation Instructions

4

ASSEMBLY AND INSTALLATION

Installation

CAUTION:

Tracks must be parallel. Small variations in

cabinet width will affect performance.

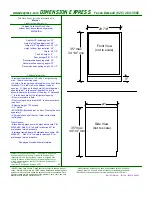

The lift tracks are designed to be mounted to the sides of the

cabinet through the prepunched holes in the base of the tracks.

IMPORTANT ! :

Allow adequate clearance around all moving

parts.

1.

Using screws of dequate length attach the motor drive side

track to left side of cabinet, keeping track even with front

edge of cabinet.

NOTE:

Top of track should be 1 1/2" below the location of the

top edge of the door panel when the panel is in the

open position.

2.

Using screws of dequate length attach the right side track to

right side of cabinet, keeping track even with front edge of

cabinet.

3.

Attach counterweight arms to the sides of the cabinet above

tracks. Hold the end of the arm with the lower wheel tight to

the top and with the notch tight against the back of the track.

NOTE:

The counterweight arms should extend 1/4" past the

front of the tracks.

IMPORTANT ! :

Use screws of adequate length.

4.

Attach counterweight cables to the wheel plates.

5.

Remove thumbnut from stud on wheel plate.

6.

Slide cable eye over threaded stud on wheel plate.

7.

Secure cable to the plate with thumbnut.

8.

Screw the door plates to back of moving door panel.

NOTE:

The plates are mounted 1/4" down from the top of the

panel with the notched corners to the top. Position the

alignment notches on either end of the plates even with

the edge of the panel.

IMPORTANT ! :

Before attaching door panel, make sure

wheel plates on left and right tracks are tight to track. If they are

not tight, loosen the red shipping screws in the center of the

plates, firmly push on outside of wheel plates, and retighten red

shipping screw.

9.

Remove hex nuts from the threaded studs on wheel plates.

10. Place adjustment slots in door plates over studs on wheel

plates, center door panel side to side on opening, and

secure with hex nuts.

Figure 1