13- 11- 605

Page 42

SECTION 6

AIR FILTER

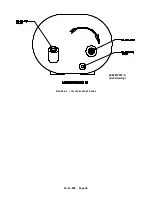

FIGURE 6--1 -- HEAVY DUTY AIR FILTER (STANDARD)

HEAVY- DUTY AIR FILTER

(FIGURE 6-- 1) furnished

as standard equipment on units with an enclosure is a

heavy-- duty washable element dry type air filter. The air

filter must receive proper maintenance if maximum ser-

vice is to be obtained from the unit. Establishing ade-

quate and timely filter service is MOST IMPORTANT.

Improperly maintained air filter can cause a loss of

compressor air delivery.

Filter Element

-- Service the air filter element when the

“CHANGE AIR FILTER” message appears on the dis-

play accompanied by a yellow indicator in the status

area of the keypad. Clean every 50 to 150 operating

hours depending on dust conditions.

Use only genuine Champion air filter

elements on Champion compressor

units. Genuine parts are available

through your authorized Champion

distributor.

To service:

1.

Remove the wingnut and pull out the filter ele-

ment.

2.

Visually inspect the element. If cleaning is not nec-

essary, reinstall the filter element. If the element

requires cleaning, go through steps 3, 4 and 5.

3.

Wash the element by soaking about 15 minutes in

warm water with a mild nonsudsing detergent.

Rinse the element thoroughly with clean water; a

hose may be used if the water pressure does not

exceed 40 psig (2.8 bar).

4.

Inspect the element for ruptures or cracks in the

pleated media; replace the element if any are

found. Inspect the gasket on the bottom (outlet

end) of the element; replace the entire element if

the gasket is damaged. A spare element will keep

down time to a minimum.

5.

Allow the element to air dry COMPLETELY. Do not

expose the element to heat over 150

_

F (66

_

C).

Install the element in the filter body and fasten se-

curely with the wing nut.

Do not oil this element. Do not wash

in inflammable cleaning fluids. Do

not use solvents other than water. Im-

proper cleaning may damage the ele-

ment.

Never operate the unit without the ele-

ment. Never use elements that are

damaged, ruptured or wet. Never use

gaskets that won’t seal. Keep spare

elements and gaskets on hand to re-

duce downtime. Store elements in a

protected area free from damage, dirt

and moisture. Handle all parts with

care.

Filter Element Life

-- The element should be replaced

after six (6) cleanings or if:

1.

Visual inspection indicates a rupture, crack or pin

hole in the pleated media. Inspection should be

done by placing a bright light inside the element.

Summary of Contents for ROTORCHAMP RCOF20

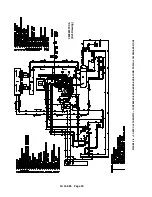

Page 13: ...13 11 605 Page 4 FIGURE 1 6 AIR WATER SCHEMATIC 300EWC797 B Ref Drawing ...

Page 16: ...13 11 605 Page 7 DECALS 206EAQ077 300EWC077 301EWC077 211EAQ077 207EAQ077 ...

Page 17: ...13 11 605 Page 8 DECALS 216EAQ077 206EWD077 222EAQ077 221EAQ077 208EAQ077 ...

Page 31: ...13 11 605 Page 22 FIGURE 4 2 FLOW CHART FOR SET UP PROGRAMMING 300EWC1255 Ref Drawing ...

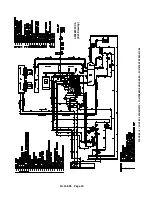

Page 41: ...13 11 605 Page 32 FIGURE 4 6 CONTROL TUBING SCHEMATIC 300EWC797 B Ref Drawing ...

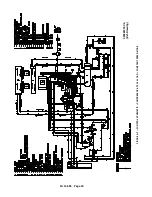

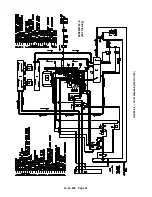

Page 45: ...13 11 605 Page 36 FIGURE 4 10 WIRING DIAGRAM FULL VOLTAGE 301EWC546 A Ref Drawing ...

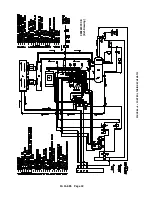

Page 46: ...13 11 605 Page 37 FIGURE 4 11 WIRING DIAGRAM WYE DELTA 302EWC546 A Ref Drawing ...

Page 47: ...13 11 605 Page 38 FIGURE 4 12 AUTO SENTRY W CONTROLLER DISPLAY ...

Page 49: ...13 11 605 Page 40 FIGURE 5 1 OIL LEVEL SIGHT GLASS 306EWC797 A Ref Drawing ...

Page 50: ...13 11 605 Page 41 FIGURE 5 2 FLOW DIAGRAM AIR COOLED 300EWC797 A Ref Drawing ...