41

condenser flow switch, temperature sensors and refrigeration

devices to allow up to 100% of the condenser heat to be re-

claimed for hot water. This means that this water-cooled con-

denser, which is in parallel with the standard air-cooled con-

denser, is capable of capturing all of the heat available from the

chiller condensing process. The leaving water temperature can

reach at maximum 131 F (55 C) under steady state and con-

stant hot water flow conditions with an allowable hot water

temperature range of 68 to 131 F (20 to 55 C). The heat reclaim

condenser fluid connections are at the end of the unit opposite

the control panel. The temperature sensor and the condenser

flow switch are mounted in the nozzles and are wired in the

control box. Refer to the Controls and Troubleshooting Book

for detailed operational information.

The heat reclaim condenser has water-side Victaulic-type

connections (follow connection directions as provided by the

coupling manufacturer). Provide proper support for the piping.

If compressor and cooler grilles have been added, holes must

be cut for field piping and insulation. A field-supplied strainer

with a minimum size of 20 mesh must be installed within 10 ft

(3.0 m) of the inlet to the heat reclaim condenser. See Fig. 32

for a typical piping diagram of the heat reclaim condenser and

3-way valve location. All piping must follow standard piping

techniques. Refer to Carrier System Design Manual or appro-

priate ASHRAE (American Society of Heating, Refrigerating,

and Air-Conditioning Engineers) handbook for details.

Two drain connections are provided, one in each head of the

condenser.

HEAD PRESSURE CONTROL — A form of head pressure

control is required while in the heat reclaim mode. In order to

meet this requirement, a properly sized 3-way valve must be

field-installed. This valve will facilitate cold water start-up

(water temperatures below 68 F [20 C]), and it also will be able

to maintain proper head pressure during heat reclaim operation.

Since the hot water temperature at start-up may be very low,

the 3-way valve is to be located as close to the heating con-

denser as possible so that this valve can quickly accomplish its

purpose of maintaining the minimum required head pressure.

Locate the 3-way valve within 40 ft (12.2 m) of the heating

condenser if the circulating pump is located between the 3-way

valve and the heat reclaim condenser. See Fig. 33A. If the

pumps are too far away from the condenser, a second option is

to install the 3-way control valve close to the condenser. See

Fig. 33B. The 30RB unit uses an anolog output to control this

valve.

CAUTION

Do not circulate water through unit without strainers in

place. Failure to use the strainers represents abuse and may

impair or otherwise negatively affect the Carrier product

warranty.

T1

T2

FS PP

PP

D

V

Heater (Optional)

Chilled Water

Out

Chilled Water

In

Isolation Valve*

20 Mesh Strainer†

Flexible Connections*

Pressure Relief*

LEGEND

*Field-supplied and installed.

D

—

Drain,

3

/

4

-in. NPT

FS

—

Flow Switch

PP

—

Pipe Plug,

1

/

4

-in. NPT

T1

—

Leaving Water Thermistor

T2

—

Entering Water Thermistor

V

—

Vent,

1

/

4

-in. NPT

Fig. 31 — Typical Piping Diagram on 30RB Units without Hydronic Package

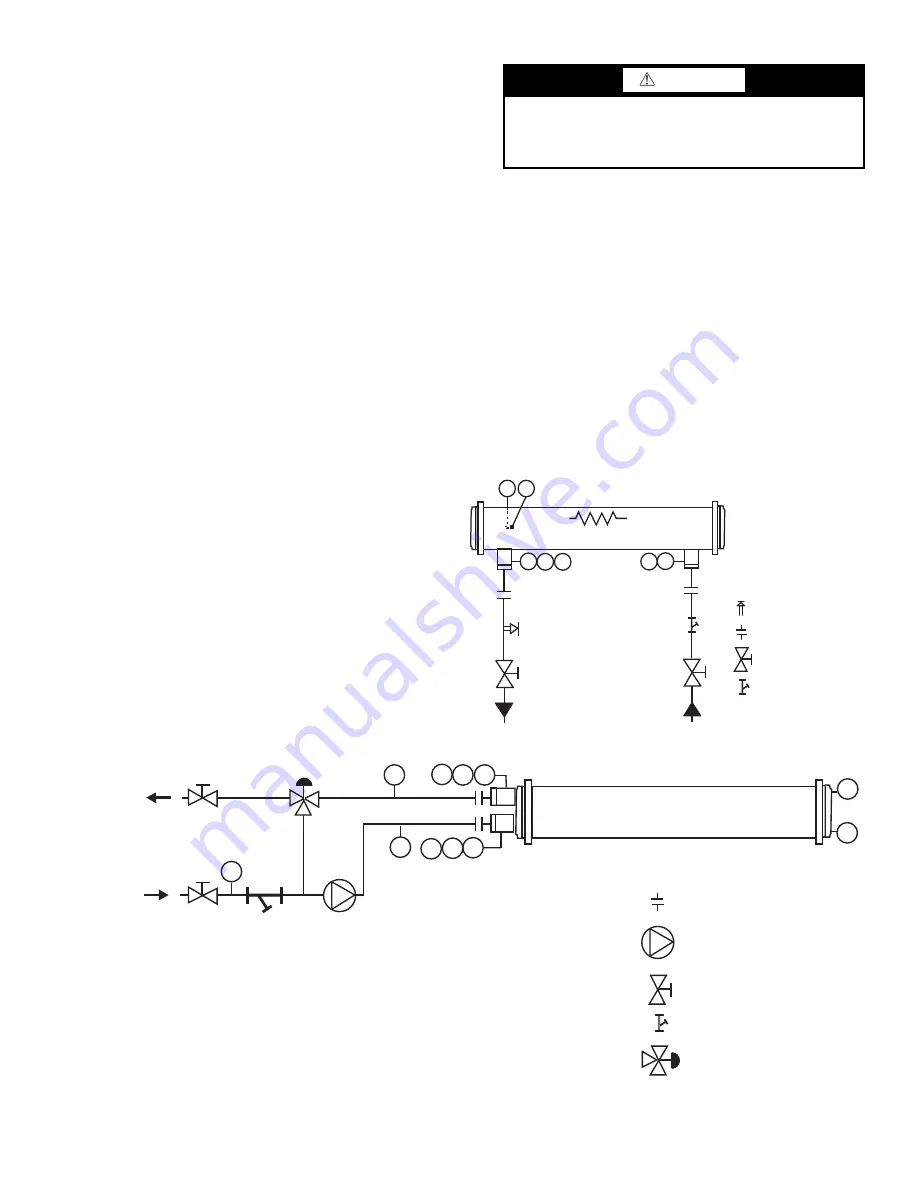

T1

T2

FS PP

PP

HEAT RECLAIM CONDENSER

HEAT

RECLAIM

RETURN

HEAT

RECLAIM

SUPPLY

Pump*

Isolation Valve*

Flexible Connections*

20 Mesh Strainer*, installed

within 10 ft (3 m) of condenser

inlet

Three-Way Valve*

V*

D*

R

D

V

D

a30-5321

Fig. 32 — Typical Piping Diagram on 30RB Units with Heat Reclaim Option

LEGEND

*Field-supplied and installed.

D*

—

Drain, Field Supplied

D

—

Drain,

3

/

8

-in. NPT

FS

—

Flow Switch

PP —

Pipe Plug,

1

/

4

-in. NPT

R

—

Pressure Relief

T1

—

Leaving Water Thermistor

T2

—

Entering Water Thermistor

V*

—

Vent, Field Supplied

V

—

Vent,

3

/

8

-in. NPT

Summary of Contents for MINIMUM LOAD CONTROL ACCESSORY 30RB060-390

Page 36: ...36 Fig 24 Unit Rigging Label Detail 30RB060 150...

Page 37: ...37 Fig 25 Unit Rigging Label Detail 30RB160 300...

Page 74: ......

Page 75: ......