Cargo Floor B.V.

Byte 14

NL-7741 MK COEVORDEN

Phone:+31 (0)524-59 39 00

www.cargofloor.com

Replacing a cylinder CF500 SL-2 / CF500 SL-C

10-12-2013

/ NL 6 van 16

Pull in the cylinders

To prevent the piston rod getting damaged in the stroke area during the repair the all the cylinders should be

pulled in fully before starting (fig. 2). In order to achieve this it is necessary to block the switching of the control

valve. Let cylinder 1 (left cylinder) run out to the front and switch off the system. Then take out the roll pin or

bolt in the bottom of the front command lip. Next, the threaded rod can be bent slightly downwards and the steel

spring on the threaded rod can be removed from the end of the threaded rod (fig.1). Turn the system back on

and the cylinders will eventually pull in fully and at the end of the ingoing stroke the pressure relieve valve will

be activated. At that time the system must be turned off. For your safety it will be advisable to disconnect the

hoses between pump and system and disconnect the electrical connections.

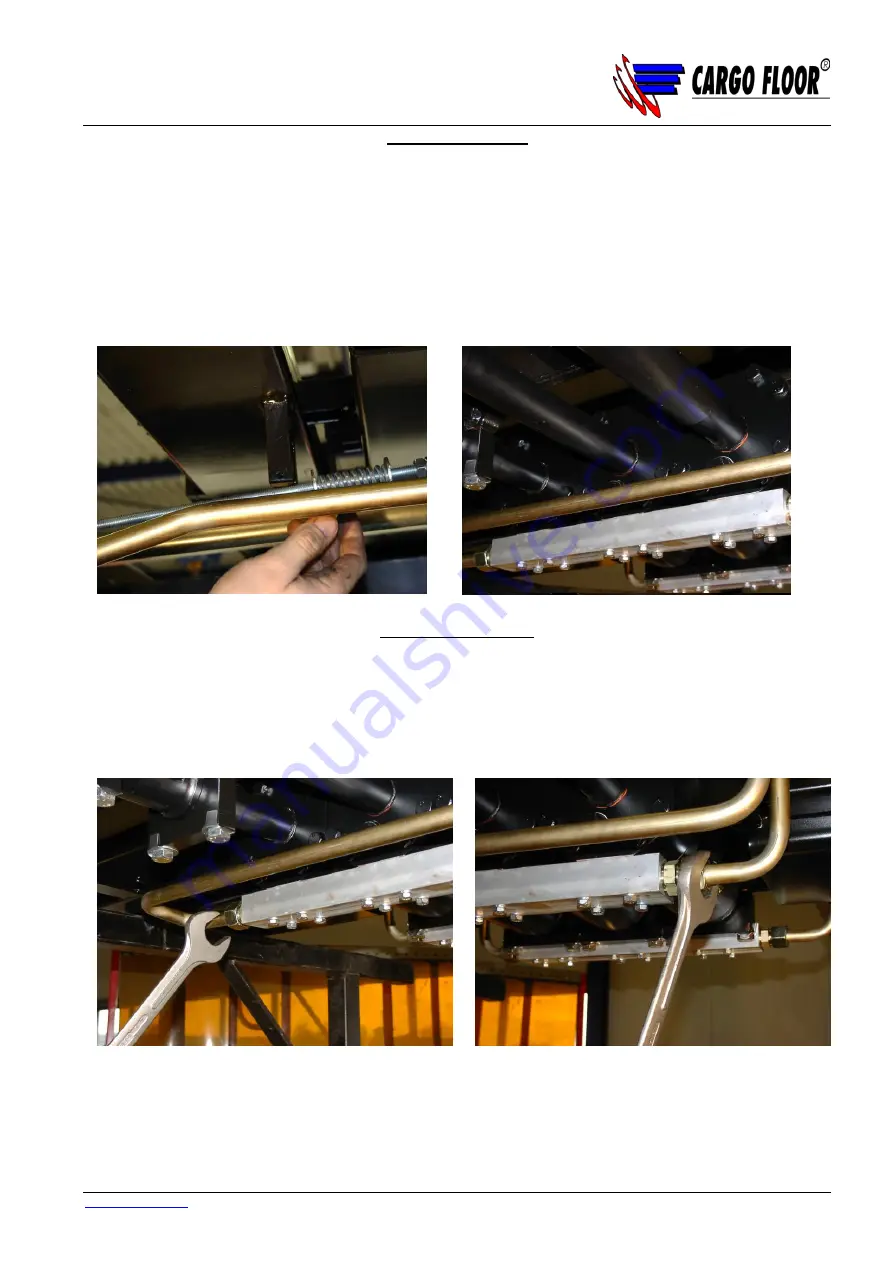

Demounting the pipes

Place a drip tray under the coupling that should be loosened and collect the leaking oil.

Unscrew the coupling screws of all 4 the pipes of the two common rails, with an open-end spanner 36 mm (fig.

3 t/m 6). If the screw-in coupling is also turning, this can be prevented with an open-end spanner 32 mm. Put

marks on the common rails, so you know how the common rail must be re-assembled. The common rails are

identical but are mounted mirrored!!!!!

Fig. 1

Fig. 2

Fig. 3

Fig. 4