11

EN

• A horizontal and vertical space of at least

20mm from the lower surface of the cooking

hob and at least 20mm from the downdraft

must be foreseen so as to create a passage

for the air necessary to cool the product (refer

to the above illustration).

• There must be an opening of at least 50mm

the whole width of the kitchen unit in the lower

and rear part of the furniture to allow for the

passage of air to avoid the product overheat-

ing.

• Ensure that the passage of air in the lower part

of the kitchen unit permits a constant flow of

air to cool the product.

• Fitting the oven underneath the cooking hob

is possible with fan-cooled ovens. Before in-

stalling the oven, remove the rear wall of the

kitchen unit where the oven will be fitted into

the kitchen furniture.

There must also be a minimum aperture of

5mm in the front part and above all in the low-

er part of the kitchen furniture to ensure an

adequate passage of air necessary to cool the

product.

Before installing the product, check that all com-

ponents are not damaged. If any components

are damaged, contact the retailer and do not go

ahead with the installation.

Before installing the downdraft, remove the safe-

ty spacer highlighted in the photograph (

Fig. 1

).

Furthermore, carefully read all the instructions as

follows:

• Utilise an air extraction duct that has a maxi-

mum length of not more than 5 metres.

• Limit the number of curves in the duct be-

cause each curve reduces the efficiency of the

extraction equal to 1 linear metre (E.g., if two

90° curves are utilised, the length of the duct

must not exceed 3 metres in length).

• Avoid drastic changes of direction.

• Utilise a duct with a 150mm or 200mm diam-

eter along its whole length.

• Utilise a duct that is manufactured from ma-

terial approved to the norm. The supplying

company will not respond to problems of flow

capacity or noise if there is a lack of respect of

the previously mentioned instructions and the

guarantee will be annulled.

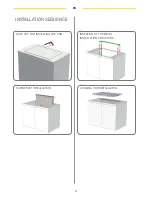

1. Position the support bracket of the down-

draft in the rear part of the realised aperture

(refer to

Fig. 2

).

2. The bracket must be positioned approxi-

mately two/three millimetres from the upper

surface of the worktop, as shown in

Fig.3

.

3. Fix the support bracket of the downdraft to

the worktop by utilising the screws supplied

in the case of wood worktops. For worktops

realised in materials different to wood, utilise

the appropriate screws.

4. Utilise the upper and lower holes positioned

in the support bracket of the downdraft in ac-

cordance with the thickness of the worktop

into which the product is installed.

5. Fix the two worktop reinforcement telescopic

structures to the lower sides of the support

bracket of the downdraft, as shown in

Fig. 4

.

6. After fixing the reinforcement structures, ad-

just their telescopic travel so as to reach the

base underneath (

Fig. 5

). Fix the structure

to the base underneath utilising the screws

supplied.

7. Check that the worktop is perfectly level then

block the travel of the structures utilising the four

self-threading screws, positioned as in

Fig. 6

.

8. Insert the downdraft into the installed sup-

port bracket (refer to

Fig. 7

). The fixtures

positioned on the downdraft must coincide

perfectly with the support bracket installed in

the kitchen unit (refer to

Fig. 8

).

Internal motor

Summary of Contents for DD931BK

Page 4: ...INDUCTION HOB 3 ...

Page 9: ...8 EN TECHNICAL DRAWING ...

Page 33: ...32 EN DOWNDRAFT ...

Page 40: ...40 IMAGES ...

Page 41: ...41 2 6 3 4 5 1 ...

Page 42: ...42 9 8 7 10 11 12 ...

Page 43: ...43 13 15 16 14 17 ...

Page 44: ...44 ...

Page 45: ...45 ...