29

EN

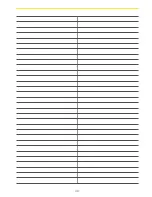

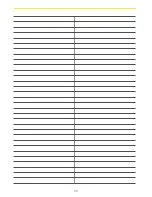

SAFETY FUNCTIONS

AND ERROR SIGNALS

ERROR CODE

ERROR DESCRIPTION

INSTRUCTION MANUAL

E03 + continuous

tone, or

Permanent use of keys; Control

unit cuts off after 10 sec. Water

or cooking utensils on the glass

above the control unit.

Cleaning of the operational sur-

face. If the problem persists,

Contact authorized center for

technical assistance - specifying

the error code.

E21

Control unit cuts off after control-

ling due to overheating to avoid

damage to electronics.

Contact authorized center for

technical assistance - specifying

the error code.

E22 or Er22

Defective Key evaluation. Con-

trol unit cuts. Short-circuit or dis-

continuation in the range of the

key evaluation.

Contact authorized center for

technical assistance - specifying

the error code.

E20 or Er20

Flash-failure Microcontroller

faulty.

Contact authorized center for

technical assistance - specifying

the error code.

E36 or Er36

Control unit cuts off. Short-cir-

cuit

Contact authorized center for

technical assistance - specifying

the error code.

E31 or Er31

Configuration data incorrect.

Configuration of induction nec-

essary.

Contact authorized center for

technical assistance - specifying

the error code.

E47 or Er47

Communication error between

TC and induction.

Contact authorized center for

technical assistance - specifying

the error code.

E2

Overheating of the induction

coils.

Contact authorized center for

technical assistance - specifying

the error code.

EA

Error on the power board. Com-

ponent failure.

Contact authorized center for

technical assistance - specifying

the error code.

U400

Secondary voltage of the power

unit to high (primary > 300V).

Control unit cuts off after 1 sec

releasing a permanent tone.

Control unit is wrongly connect-

ed.

1) Contact authorized center for

technical assistance - specifying

the error code.

2) Contact an electrician check

your home network..

E5

Error on filter board.

Contact authorized center for

technical assistance - specifying

the error code.

Summary of Contents for DD931BK

Page 4: ...INDUCTION HOB 3 ...

Page 9: ...8 EN TECHNICAL DRAWING ...

Page 33: ...32 EN DOWNDRAFT ...

Page 40: ...40 IMAGES ...

Page 41: ...41 2 6 3 4 5 1 ...

Page 42: ...42 9 8 7 10 11 12 ...

Page 43: ...43 13 15 16 14 17 ...

Page 44: ...44 ...

Page 45: ...45 ...