19

On the inside of the hull, grind also

about one inch around the hole, to remove

existing paint and expose bare fibreglass.

(Before applying the epoxy and glassfibre,

make sure you have drilled the holes for

the struts holding the forward end of the

tube)

Apply a coat of epoxy (with

hardener) to the ground portion of the tube,

and also to the inside and sides of the hole

in the hull.

Thicken the epoxy with filler until it

does not sag when you take a gob at the

end of a stick and hold it for about 10

seconds. Fill the gap between the tube and hull and make a fillet inside. For an even

better joint, you may add one or two layers 2 inch wide glass tape.

Epoxy resin provides a better adhesion to cured fibreglass than polyester. If

you are using the West System, filler no. 404 is best (you will need less), but 403 and

406 will provide adequate mechanical strength; 405 is for wood.

Uncured epoxy can be cleaned with alcohol (methylated spirits), which is less

“aggressive” than acetone.

A light bead of sealant will make a nice finish outside.

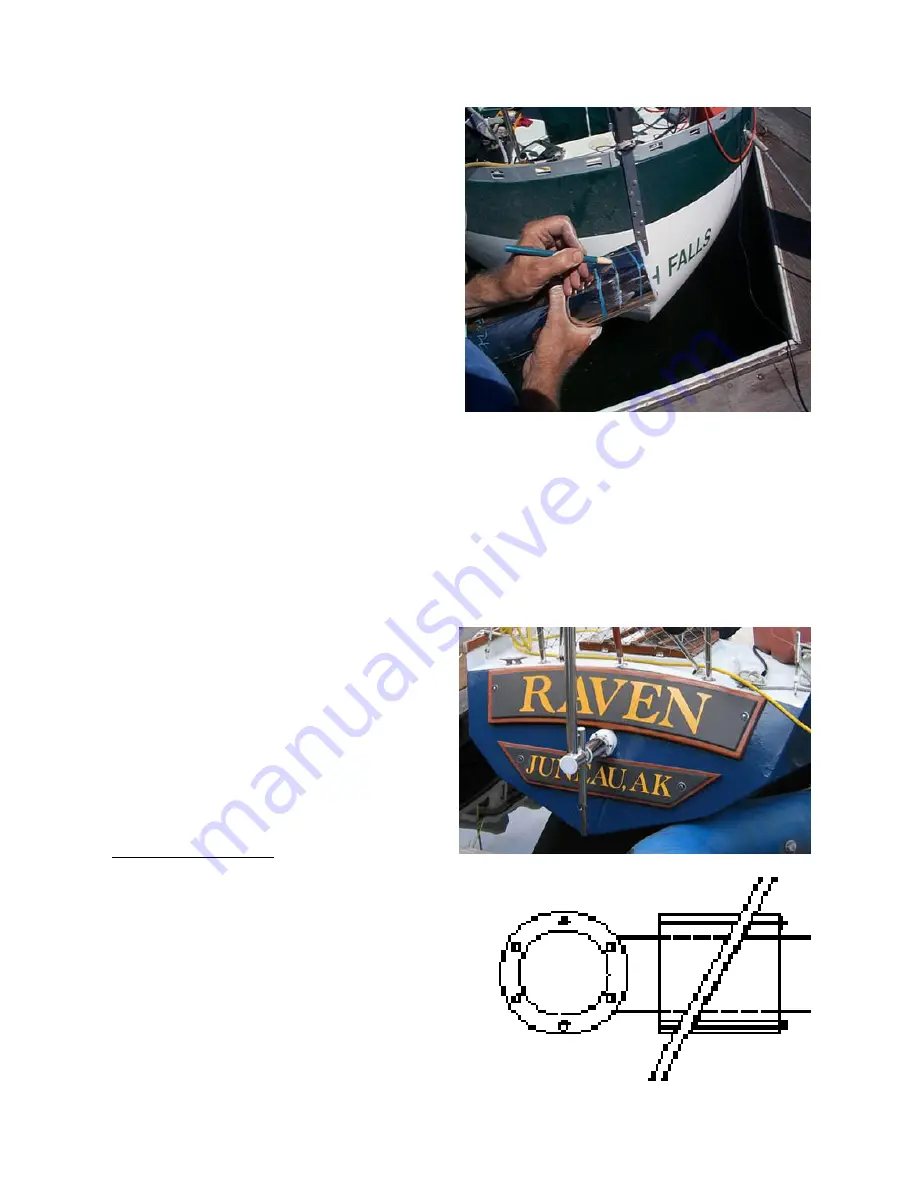

Metal Hulls

The Mounting Tube can be welded

to a steel hull, provided welding is done

carefully to minimize tube deformation.

An aluminum Mounting Tube can

be supplied for welding to an aluminum

hull.

If welding is not practical, an optional

Delrin collar adapter can be used to bond

the tube to the hull.

The collar is cut to the angle of the

transom, and the two halves are inserted over

the mounting tube one from the inside, the

other from the outside, taking the transom in

sandwich, and the two halves are bolted

together, using a liberal amount of sealant to fill

all voids..

If we are given the angle the transom

makes with the horizontal, this collar can be