Specifications

4-13

4

Appe

ndix

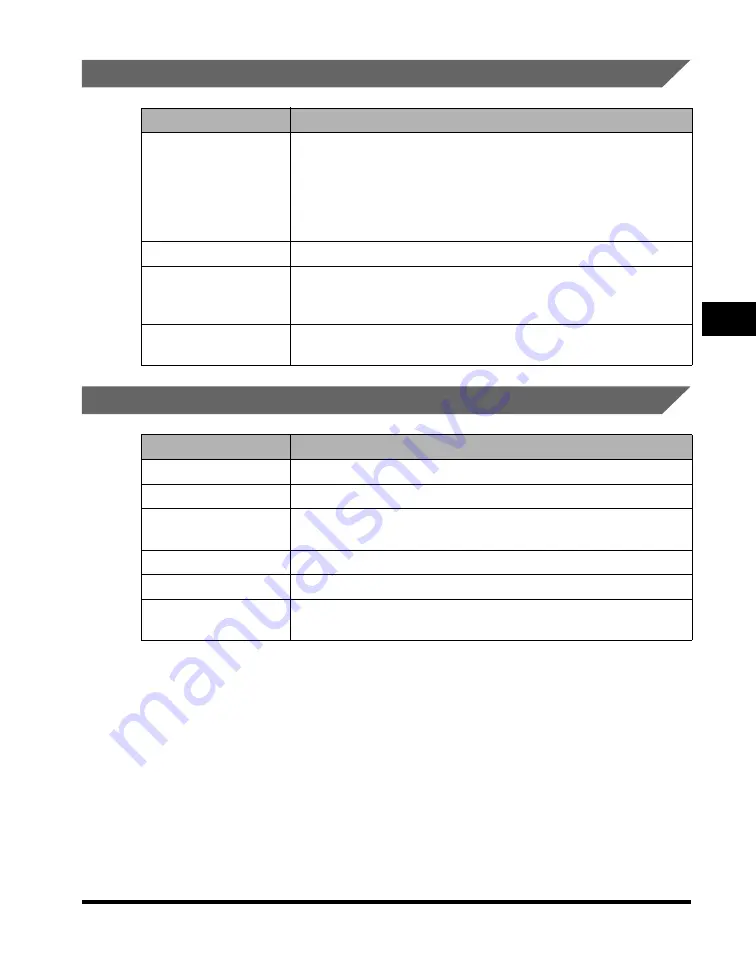

Copy Tray-L1

Card Reader-C1

Item

Specification

Paper Size/Weight/

Type

Size: 11" x 17", LGL, LTR, LTRR, STMTR, EXEC, Free size (3 7/8"

x 5 7/8" to 11 5/8" x 17" (99 mm x 148 mm to 297 mm x 432 mm))

Weight: 17 lb bond to 110 lb index (64 to 200 g/m

2

)

Type: Plain, Recycled, Color, Pre-punched, Heavy (24 lb bond to

110 lb index (91 to 200 g/m

2

)), Bond, Letterhead, Tracing Paper,

Transparency, Labels, Tab Paper

Capacity

250 sheets (20 lb bond (80 g/m

2

))

Dimensions (H x W x

D)/Weight

7 3/8" x 17 5/8" x 13 3/8" (186 mm x 446 mm x 340 mm)

(when the auxiliary tray and wire are extended)/

Approximately 1.5 lb (670 g)

Installation Space (W

x D)

42 7/8" x 29 1/4" (1,089 mm x 743 mm)

Item

Specification

Available Cards

Optical

Card Readout Method

Optical readout

Magnetic Card

Reading Direction

Face up

Store/Replay

Replay

Power Source

From the main unit

Dimensions (H x W x

D)/Weight

1 1/4" x 3 1/2" x 4" (32 mm x 88 mm x 100 mm)

Approximately 10.4 oz (295 g)

Summary of Contents for imageRUNNER 5075

Page 2: ......

Page 3: ...imageRUNNER 5075 5065 5055 5050 Support Guide 0 Ot...

Page 40: ...xxxviii...

Page 68: ...System Settings 1 28 1 Before You Start Using This Machine...

Page 138: ...Consumables 2 70 2 Routine Maintenance...

Page 242: ...When the Power Does Not Turn ON 3 104 3 Troubleshooting...

Page 266: ...System Management of the imageRUNNER 5075 5065 5055 5050 4 24 4 Appendix...

Page 267: ......