p.

2

- M

an

u

al

:

F

A

0

0

6

1

3

-E

N

FA

0

0

6

1

3

-E

N

v.

1

1

- 1

1/

2

0

1

6 - © C

A

M

E S

.p.

A

. T

h

e d

ata a

n

d i

nf

or

m

ati

on i

n th

is

m

an

u

al

m

ay b

e c

h

an

g

ed at a

ny ti

m

e a

n

d w

ith

ou

t n

oti

ce

.

WARNING!

important safety instructions for people:

READ CAREFULLY!

P

REMISE

• T

HIS

PRODUCT

SHOULD

ONLY

BE

USED

FOR

THE

PURPOSE

FOR

WHICH

IT

WAS

EXPLICITLY

DESIGNED

. A

NY

OTHER

USE

IS

DANGEROUS

. C

AME

S.

P

.A.

IS

NOT

LIABLE

FOR

ANY

DAMAGE

CAUSED

BY

IMPROPER

,

WRONGFUL

AND

UNREASONABLE

USE

•

T

HE

SAFETY

OF

THIS

PRODUCT

AND

ITS

PROPER

FITTING

DEPENDS

,

THEREFORE

,

ON

RESPECTING

ITS

TECHNICAL

CHARACTERISTICS

AND

PROPER

FITTING

,

TO

BE

DONE

IN

STATE

-

OF

-

THE

-

ART

FASHION

,

AND

UNDER

SAFE

CONDITIONS

AS

EXPRESSLY

EXPLAINED

IN

THE

LITERATURE

THAT

COMES

WITH

THE

PRODUCT

• K

EEP

THESE

WARNINGS

TOGETHER

WITH

THE

INSTALLATION

AND

OPERATION

MANUALS

THAT

COME

WITH

THE

OPERATOR

.

B

EFORE

INSTALLING

(

CHECKING

WHAT

'

S

THERE

:

IF

SOMETHING

IS

MISSING

,

DO

NOT

CONTINUE

UNTIL

YOU

HAVE

COMPLIED

WITH

ALL

SAFETY

PROVISIONS

)

• F

ITTING

AND

TESTING

MUST

BE

BE

ONLY

PERFORMED

BY

QUALIFIED

TECHNICIANS

•

LAYING

THE

CABLES

,

INSTALLATION

AND

TESTING

MUST

FOLLOW

STATE

-

OF

-

THE

-

ART

PROCEDURES

AS

DICTATED

BY

REGULATIONS

•

BEFORE

BEGINNING

ANY

OPERATION

IT

IS

MANDATORY

TO

CAREFULLY

READ

ALL

INSTRUCTIONS

;

IMPROPER

INSTALLATION

MAY

RESULT

IN

SERIOUS

HARM

TO

PEOPLE

AND

THINGS

.•

MAKE

SURE

THE

OPERATOR

IS

IN

GOOD

MECHANICAL

STATE

,

BALANCED

AND

ALIGNED

,

AND

THAT

IT

OPENS

AND

CLOSES

PROPERLY

. A

LSO

,

IF

NEEDED

,

FIT

SUITABLE

PROTECTIONS

O

USE

PROPER

SAFETY

SEN

-

SORS

•

MAKE

SURE

THAT

THE

OPENING

TURNSTILE

CANNOT

RESULT

IN

ANY

HAZARDS

•

DO

NOT

INSTALL

THE

OPERATOR

ONTO

SURFACES

THAT

COULD

YIELD

AND

BEND

.

I

F

NECESSARY

,

ADD

SUITABLE

REINFORCEMENTS

TO

THE

ANCHORING

POINTS

•

ONLY

INSTALL

ON

A

LEVEL

SURFACE

•

MAKE

SURE

ANY

SPRINKLER

SYSTEMS

CANNOT

WET

THE

OPERATOR

FROM

THE

GROUND

UP

.

I

NSTALLING

• S

UITABLY

SECTION

OFF

AND

DEMARCATE

THE

ENTIRE

INSTALLATION

SITE

TO

PREVENT

UNAUTHORIZED

PERSONS

FROM

ENTERING

THE

AREA

,

ESPECIALLY

MINORS

AND

CHIL

-

DREN

•

BE

CAREFUL

WHEN

HANDLING

OPERATORS

THAT

WEIGH

OVER

25

KG

. I

F

NEED

BE

,

USE

PROPER

SAFETY

HOISTING

EQUIPMENT

•

THE

CE-

MARKED

SAFETY

DEVICES

,

MUST

BE

FITTED

IN

COMPLIANCE

WITH

THE

REGULATIONS

IN

EFFECT

AND

ACCORDING

TO

STATE

-

OF

-

THE

-

ART

CRITERIA

,

TAKING

INTO

ACCOUNT

THE

ENVIRONMENT

,

THE

TYPE

OF

REQUIRED

SERVICE

AND

OF

THE

WORKING

FORCES

APPLIED

TO

MOVING

TURNSTILES

.

A

NY

CRUSHING

SHEARING

OR

CONVEYING

POINTS

MUST

BE

SUITABLY

PROTECTED

•

A

NY

RESIDUAL

RISKS

MUST

BE

POINTED

OUT

TO

END

USERS

AND

HIGHLIGHTED

WITH

PICTOGRAMS

AS

PROVIDED

BY

THE

LAW

•

ALL

OPENING

COMMANDS

(

THAT

IS

,

BUT

-

TONS

,

KEY

SWITCHES

,

MAGNETIC

READERS

,

AND

SO

ON

)

MUST

BE

INSTALLED

AT

LEAST

1.85

M

FROM

THE

PERIMETER

OF

THE

TURNSTILE

'

S

WORKING

AREA

,

OR

WHERE

THEY

CANNOT

BE

REACHED

FROM

OUTSIDE

THE

TURNSTILE

. A

LSO

,

ANY

DIRECT

COMMANDS

(

BUTTONS

,

TOUCH

PANELS

,

AND

SO

ON

)

MUST

BE

INSTALLED

AT

LEAST

1.5

M

FROM

THE

GROUND

AND

MUST

NOT

BE

REACHABLE

BY

UNAUTHORIZED

PERSONS

•

THE

TURNSTILE

MUST

CLEARLY

DISPLAY

ITS

OWN

IDENTIFICATION

DATA

•

BEFORE

CONNECT

-

ING

THE

TURNSTILE

TO

THE

POWER

SUPPLY

MAKE

SURE

THAT

THE

IDENTIFICATION

DATA

MATCH

THE

NETWORK

DATA

•

THE

TURNSTILE

MUST

BE

CONNECTED

TO

AN

EFFICIENT

,

STATE

-

OF

-

THE

-

ART

GROUNDING

SYSTEM

•

THE

MANUFACTURER

DECLINES

ANY

LI

-

ABILITY

FOR

USING

NON

-

ORIGINAL

PRODUCTS

;

WHICH

WOULD

RESULT

IN

WARRANTY

LOSS

• B

EFORE

DELIVERING

TO

THE

USERS

,

MAKE

SURE

THE

SYSTEM

IS

EN 12453

AND

EN 12445

STANDARD

COMPLIANT

,

AND

ALSO

MAKE

SURE

THE

SYSTEM

HAS

BEEN

PROPERLY

ADJUSTED

AND

THAT

ANY

SAFETY

,

PROTECTION

AND

MANUAL

RELEASE

DEVICES

ARE

WORKING

PROPERLY

•

APPLY

WARNING

SIGNS

WHERE

NECESSARY

AND

IN

A

VISIBLE

PLACE

.

S

PECIAL

INSTRUCTIONS

AND

RECOMMENDATIONS

FOR

USERS

• K

EEP

TURNSTILE

OPERATION

AREAS

CLEAN

AND

FREE

OF

ANY

OBSTRUCTIONS

.

M

AKE

SURE

THE

PHOTOCELL

'

S

OPERATING

FIELD

IS

CLEAR

OF

ANY

OBSTRUCTIONS

•

DO

NOT

ALLOW

CHILDREN

TO

PLAY

WITH

FIXED

COMMANDS

,

OR

TO

LOITER

IN

THE

TURNSTILE

'

S

MANEUVERING

AREA

. K

EEP

ANY

REMOTE

CONTROL

TRANSMITTERS

OR

ANY

OTHER

COMMAND

DEVICE

AWAY

FROM

CHILDREN

,

TO

PREVENT

THE

OPERATOR

FROM

BEING

ACCIDENTALLY

ACTIVATED

•

THE

APPARATUS

MAY

BE

USED

BY

CHILDREN

OF

EIGHT

YEARS

AND

ABOVE

AND

BY

PHYSICALLY

,

MENTALLY

AND

SENSORY

-

CHAL

-

LENGED

PEOPLE

,

OR

EVEN

ONES

WITHOUT

ANY

EXPERIENCE

,

PROVIDED

THIS

HAPPENS

UNDER

CLOSE

SUPERVISION

OR

ONCE

THEY

HAVE

BEEN

PROPERLY

INSTRUCTED

TO

USE

THE

APPARATUS

SAFELY

AND

TO

THE

POTENTIAL

HAZARDS

INVOLVED

. C

LEANING

AND

MAINTENANCE

BY

USERS

MUST

NOT

BE

DONE

BY

CHILDREN

,

UNLESS

PROPERLY

SUPERVISED

.• F

REQUENTLY

CHECK

THE

SYSTEM

FOR

ANY

MALFUNCTIONS

OR

SIGNS

OF

WEAR

AND

TEAR

OR

DAMAGE

TO

THE

MOVING

STRUCTURES

,

TO

THE

COMPONENT

PARTS

,

ALL

ANCHORING

POINTS

,

INCLUDING

CABLES

AND

ANY

ACCESSIBLE

CONNEC

-

TIONS

. K

EEP

ANY

HINGES

,

MOVING

JOINTS

AND

FRICTION

POINTS

PROPERLY

LUBRI

-

CATED

•

PERFORM

FUNCTIONAL

CHECKS

ON

THE

PHOTOCELLS

AND

SENSITIVE

SAFETY

EDGES

,

EVERY

SIX

MONTHS

. C

ONSTANTLY

CLEAN

THE

PHOTOCELLS

'

GLASS

COVERS

USING

A

SLIGHTLY

WATER

-

MOISTENED

CLOTH

;

DO

NOT

USE

SOLVENTS

OR

CHEMICALS

THAT

COULD

DAMAGE

THE

DEVICES

• I

F

REPAIRS

OR

MODIFICATIONS

ARE

REQUIRED

TO

THE

SYSTEM

,

CUT

OFF

THE

MAIN

POWER

SUPPLY

AND

DO

NOT

USE

IT

UNTIL

SAFETY

CONDITIONS

HAVE

BEEN

RESTORED

• C

UT

OFF

THE

POWER

SUPPLY

BEFORE

PERFORM

-

ING

ANY

MANUAL

OPENINGS

. I

F

THE

POWER

SUPPLY

CABLE

IS

DAMAGED

,

IT

MUST

BE

REPLACED

BY

THE

MANUFACTURER

OR

AUTHORIZED

TECHNICAL

ASSISTANCE

SERVICE

,

OR

IN

ANY

CASE

,

BY

SIMILARLY

QUALIFIED

PERSONS

,

TO

PREVENT

ANY

RISK

• I

T

IS

FORBIDDEN

FOR

USERS

TO

PERFORM

ANY

OPERATIONS

THAT

ARE

NOT

EXPRESSLY

REQUIRED

OF

THEM

. F

OR

ANY

REPAIRS

,

MODIFICATIONS

AND

ADJUSTMENTS

AND

FOR

EXTRA

-

ORDINARY

MAINTENANCE

,

CALL

TECHNICAL

ASSISTANCE

•

LOG

THE

JOBS

AND

CHECKS

INTO

THE

PERIODIC

MAINTENANCE

LOG

.

A

DDITIONAL

INSTRUCTIONS

AND

RECOMMENDATIONS

FOR

EVERYONE

• K

EEP

AWAY

FROM

AND

DO

NOT

LOITER

NEAR

THE

BARRIER

AND

MECHANICAL

MOV

-

ING

PARTS

•

DO

NOT

ENTER

THE

BARRIER

'

S

AREA

OF

OPERATION

WHEN

IT

IS

MOVING

•

DO

NOT

COUNTER

THE

OPERATOR

'

S

MOVEMENT

AS

THIS

COULD

RESULT

IN

DANGER

-

OUS

SITUATIONS

•

ALWAYS

PAY

SPECIAL

ATTENTION

TO

ANY

DANGEROUS

POINTS

,

WHICH

HAVE

TO

BE

LABELED

WITH

SPECIFIC

PICTOGRAMS

AND

/

OR

BLACK

AND

YELLOW

STRIPES

•

WHEN

USING

A

SELECTOR

SWITCH

OR

A

COMMAND

IN

MAINTAINED

ACTION

MODE

,

KEEP

CHECKING

THAT

THERE

ARE

NO

PERSONS

WITHIN

THE

OPERATING

RANGE

OF

ANY

MOVING

PARTS

,

UNTIL

THE

COMMAND

IS

RELEASED

•

THE

TURNSTILE

MAY

MOVE

AT

ANY

TIME

AND

WITHOUT

WARNING

•

ALWAYS

CUT

OFF

THE

MAINS

POWER

SUPPLY

BEFORE

PERFORMING

ANY

MAINTENANCE

OR

CLEANING

.

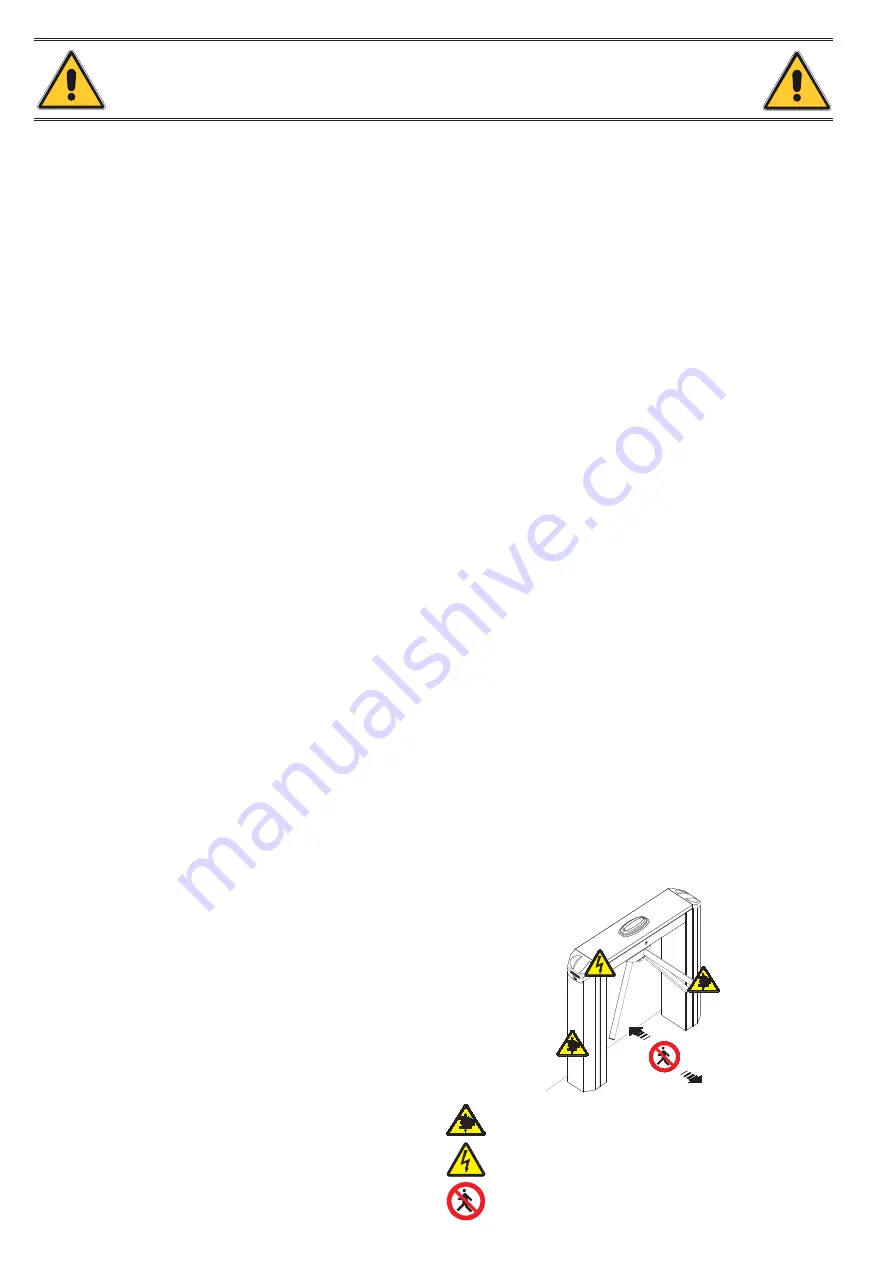

D

ANGER

OF

HAND

CRUSHING

D

ANGER

! H

IGH

VOLTAGE

.

N

O

TRANSITING

WHILE

THE

BARRIER

IS

MOVING